Method for preparing blue long afterglow luminescence C12A7 powder

A long afterglow luminescence, dodecacalcium technology, applied in the field of materials, can solve the problem of high synthesis temperature and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

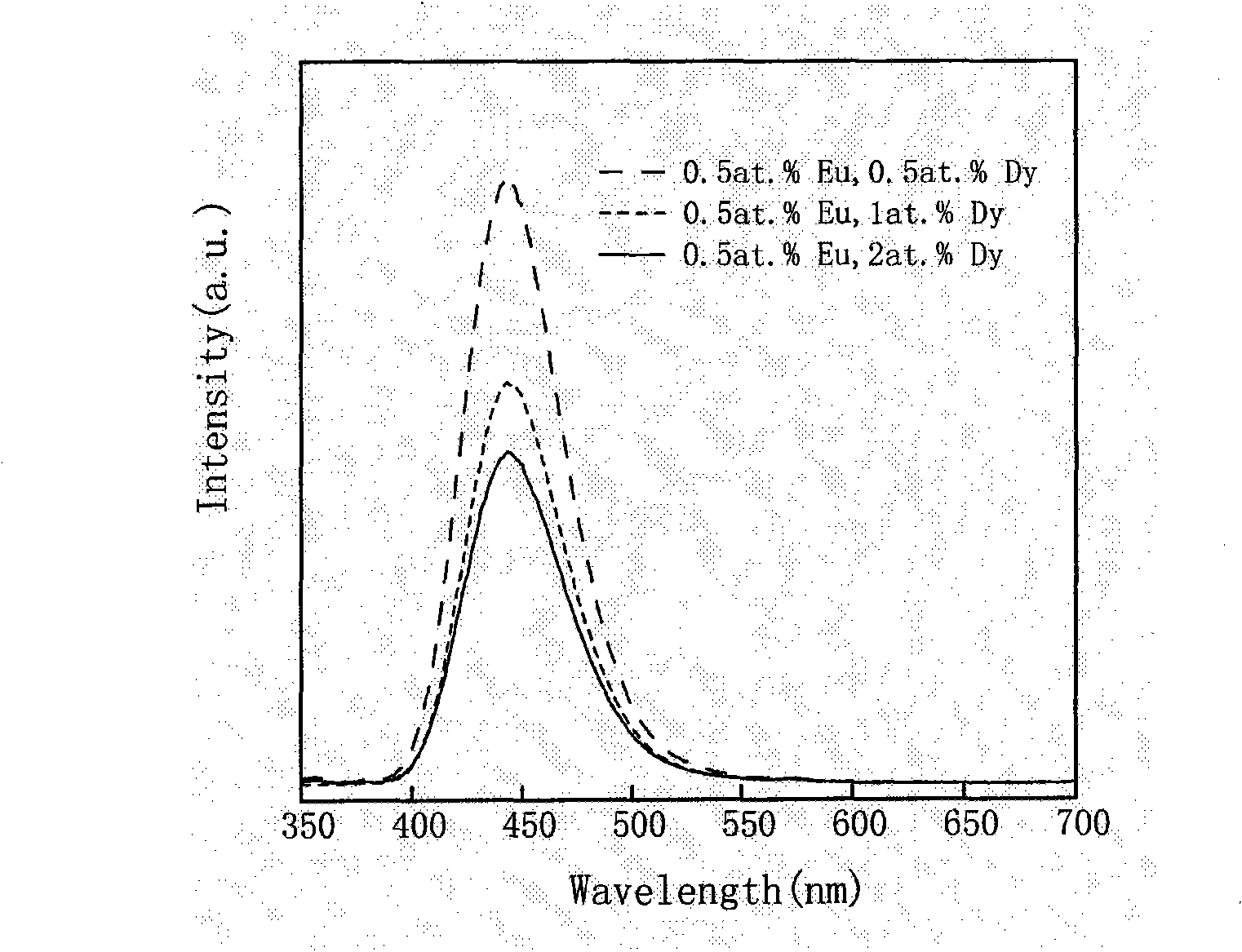

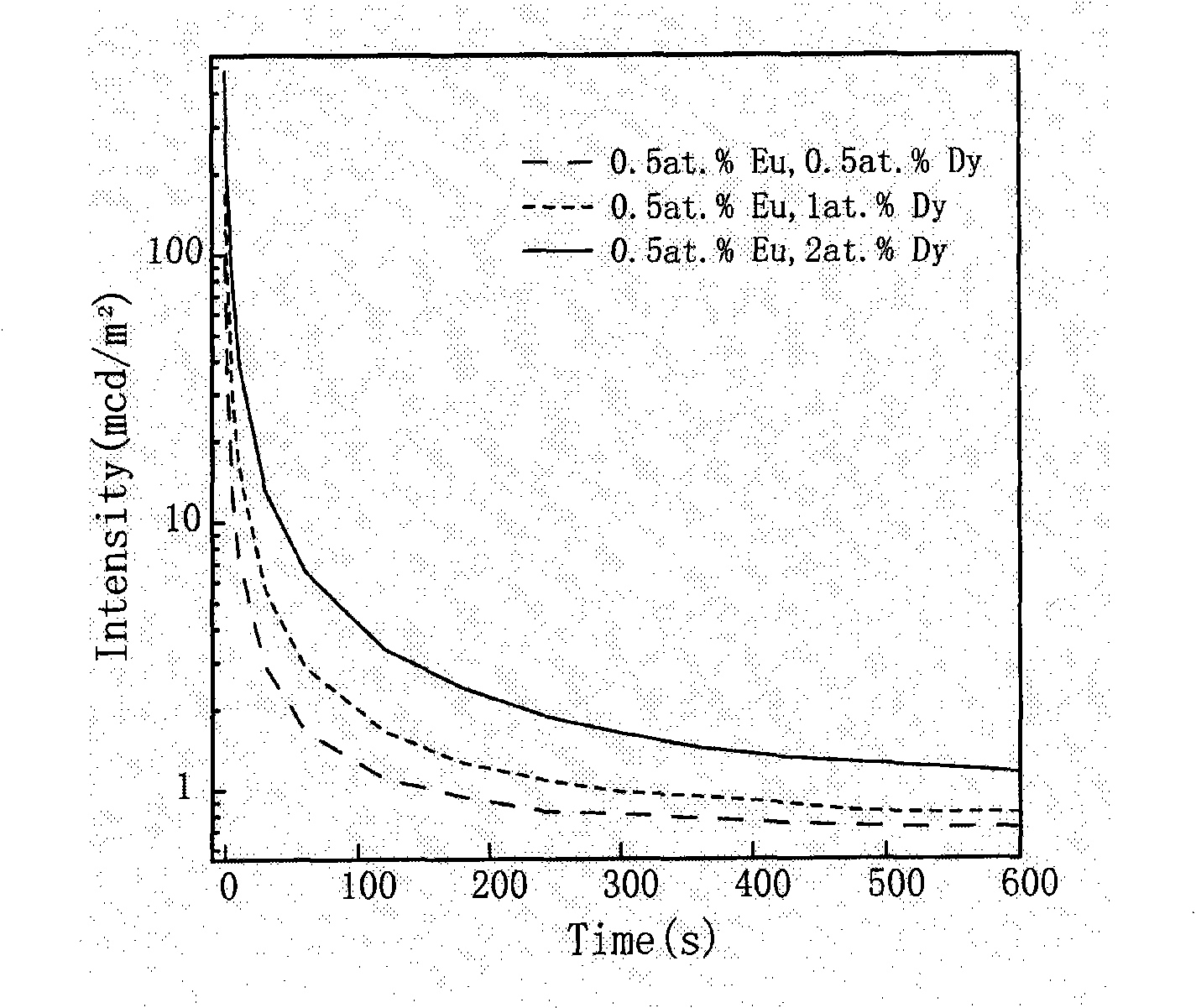

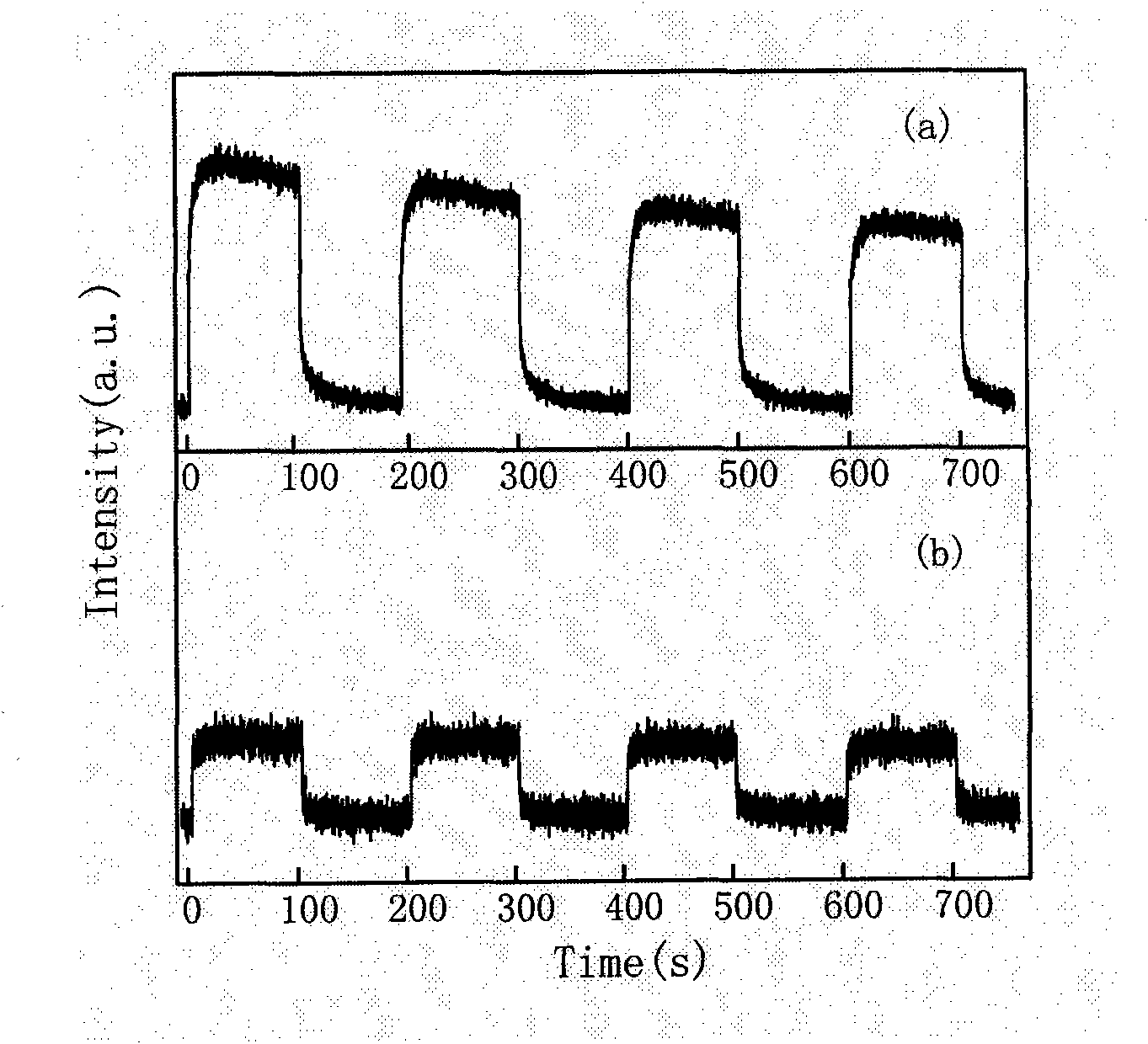

Embodiment 1

[0023] 1. Weigh 0.0114g of Eu with a purity of 99.99% 2 o 3 , 0.0121g with a purity of 99.99% Dy 2 o 3 , dissolved in HNO under heating 3 In, made into nitrate solution;

[0024] 2. the 5.6838g purity is 99.99% Al (NO 3 ) 3 and 3.0669g of 99.99% pure Ca(NO 3 ) 2 The raw materials are dissolved in deionized water according to the chemical dosage ratio;

[0025] 3. Mix the above two solutions evenly and add the precipitating agent NH 3 ·H 2 O, to obtain the gel precursor;

[0026] 4. Dry the obtained gel precursor at 100°C to remove water;

[0027] 5. Put the obtained gel into a high-temperature furnace, sinter in an air atmosphere at 1100°C for 6 hours, cool, grind, and sinter and reduce the obtained powder in an activated carbon reducing atmosphere at 1000°C for 2 hours to obtain 0.5 Calcium heptaaluminate powder co-doped with % europium and 0.5% dysprosium (C12A7: 0.5% Eu, 0.5% Dy).

Embodiment 2

[0029] 1. Weigh 0.0114g of Eu with a purity of 99.99% 2 o 3 , 0.0242g with a purity of 99.99% Dy 2 o 3 , dissolved in HNO under heating 3 In, made into nitrate solution;

[0030] 2. the 5.6838g purity is 99.99% Al (NO 3 ) 3 and 3.0669g of 99.99% pure Ca(NO 3 ) 2 The raw materials are dissolved in deionized water according to the chemical dosage ratio;

[0031] 3. Mix the above two solutions evenly and add the precipitating agent NH 3 ·H 2 O, to obtain the gel precursor;

[0032] 4. Dry the obtained gel precursor at a temperature of 90°C to remove water;

[0033] 5. Put the obtained gel into a high-temperature furnace, sinter in an air atmosphere at 1200°C for 7 hours, cool, grind, and sinter and reduce the obtained powder in an activated carbon reducing atmosphere at 1050°C for 3 hours to obtain 0.5 Calcium heptaaluminate powder co-doped with % europium and 1% dysprosium (C12A7: 0.5% Eu, 1% Dy).

Embodiment 3

[0035] 1. Weigh 0.0114g of Eu with a purity of 99.99% 2 o 3 , 0.0484g with a purity of 99.99% Dy 2 o 3 , dissolved in HNO under heating 3 In, made into nitrate solution;

[0036] 2. the 5.6838g purity is 99.99% Al (NO 3 ) 3 and 3.0669g of 99.99% pure Ca(NO 3 ) 2 The raw materials are dissolved in deionized water according to the chemical dosage ratio;

[0037] 3. Mix the above two solutions evenly and add the precipitating agent NH 3 ·H 2 O, to obtain the gel precursor;

[0038] 4. Dry the obtained gel precursor at a temperature of 120°C to remove water;

[0039] 5. Put the obtained gel in a high-temperature furnace, sinter in an air atmosphere at 1100°C for 8 hours, cool and grind, and sinter and reduce the obtained powder in an activated carbon reducing atmosphere at 1100°C for 4 hours to obtain 0.5 Calcium heptaaluminate powder co-doped with % europium and 2% dysprosium (C12A7: 0.5% Eu, 2% Dy).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com