Jet flow and blade combined pump

A vane-type, composite pump technology, applied in the field of composite pumps, can solve the problems of two long connecting pipelines, cumbersome installation procedures, etc., and achieve the effects of saving costs, reducing use and storage space, and saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

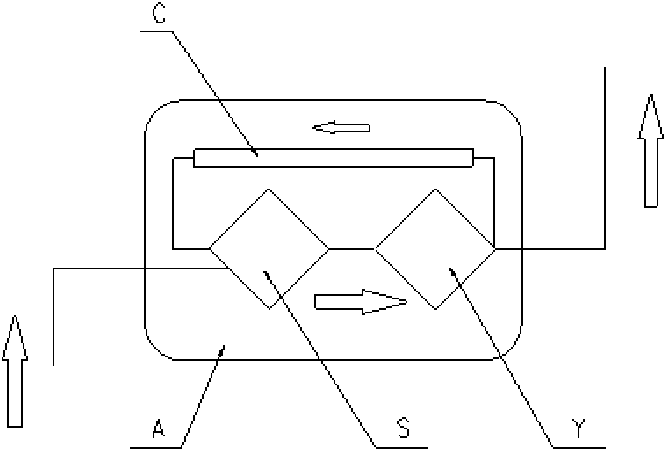

[0027] exist figure 1 The schematic diagram of the principle of the present invention is shown in , A is the whole compound pump, S is the jet pump, Y is the vane pump, C is the liquid storage chamber; the arrow indicates the direction of fluid flow.

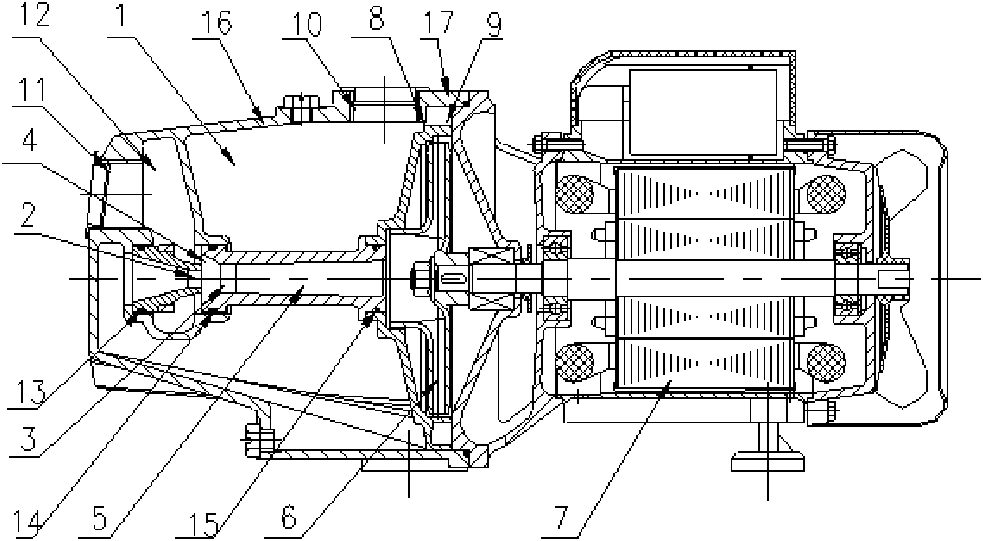

[0028] Such as figure 2 As shown, the jet pump is composed of an input port 11, a nozzle 2 connected to the liquid storage chamber 1, a throat pipe 3 and a diffuser pipe 5; the vane pump is composed of an impeller 6, a volute 17, an output port 10 and a motor 7; The liquid storage chamber 1 is arranged between the inner side of the housing 16 and the periphery of the diffusion pipe 5, and the inside of the volute 17 is a pressurized water chamber 9, which communicates with the liquid storage chamber 1 through the channel 8 on its side; 1. The connected nozzle 2 is facing the center of the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com