Swinging-bucket type rotor pump

A rotor and casing technology, applied in the field of positive displacement fluid pumps, can solve the problems of short life, wear, and inability to form a high lift, and achieve the effect of improving the rotational speed and structural strength, and improving the lift and flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

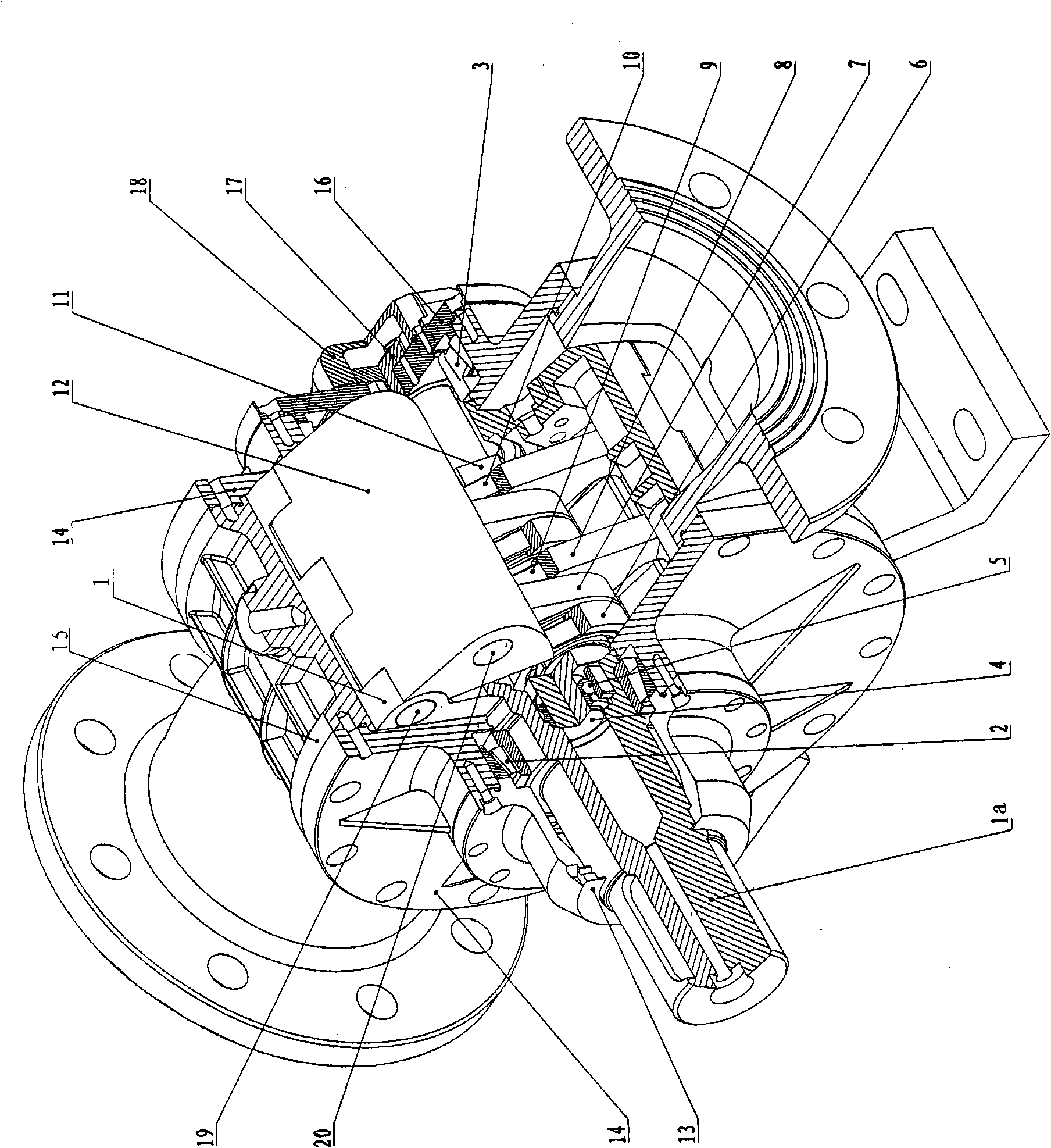

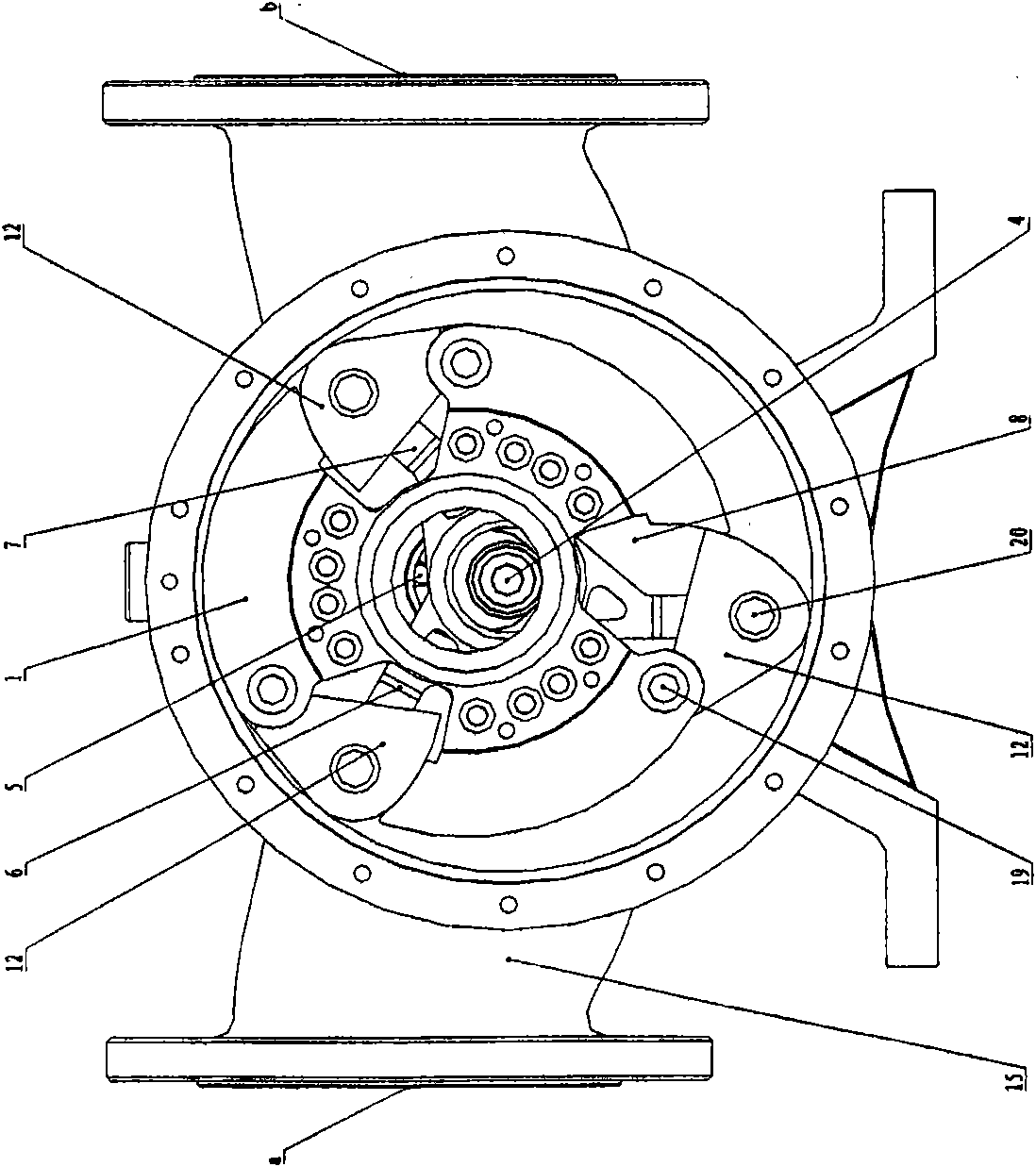

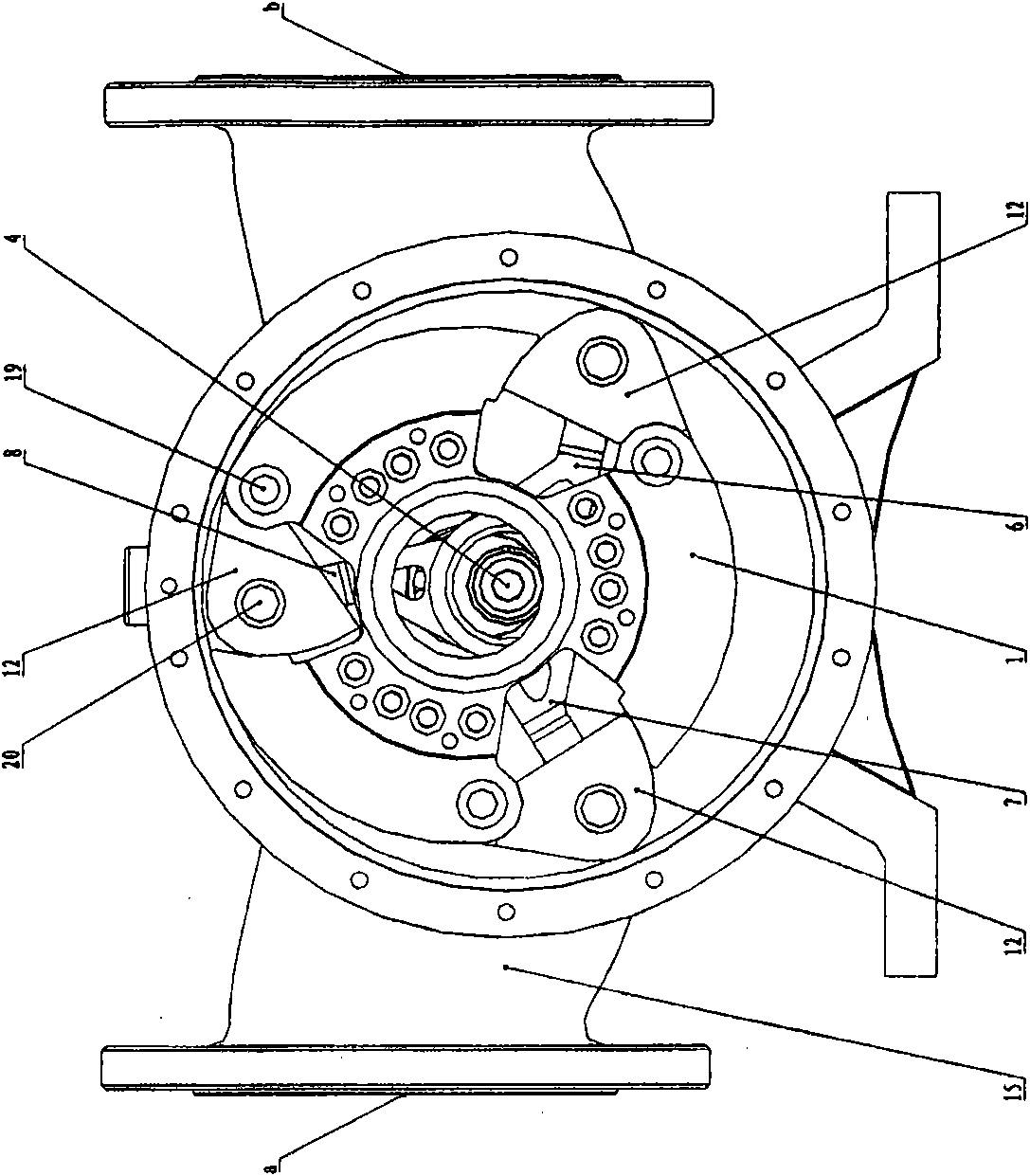

[0019] figure 1 Shown in is an exemplary embodiment of an oscillating bucket rotor pump according to the invention, which has a cylindrical housing 15 with a chamber for receiving the rotor 1 . The front end covers 13 and 14 and the rear end covers 16 and 18 are mounted on the front and rear sides of the casing 15 respectively in the axial direction, and are fastened into one body with bolts and positioned by pins.

[0020] External devices of the rotor pump, such as motors, input devices (such as shaft couplings), inlet and outlet pipes, and equipment with the rotor pump, are well known to those skilled in the art, so descriptions thereof are omitted here.

[0021] continue to see figure 1 , the cylindrical rotor 1 is eccentrically arranged in the chamber of the cylindrical housing 15, and the rotor 1 is not cut from the inner wall of the housing delimiting the chamber. One end 1 a of the central shaft of the rotor 1 protrudes through front end covers 13 , 14 to receive pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com