Electromagnetic water heater without liner and electromagnetic thermal conductor thereof

A technology of heat conductors and water heaters, applied in water heaters, fluid heaters, induction heating, etc., can solve the problems of water temperature not meeting the use requirements, low heat transfer efficiency, and easy leakage, etc., to achieve continuous and stable hot water supply, High heat transfer efficiency and fast water temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

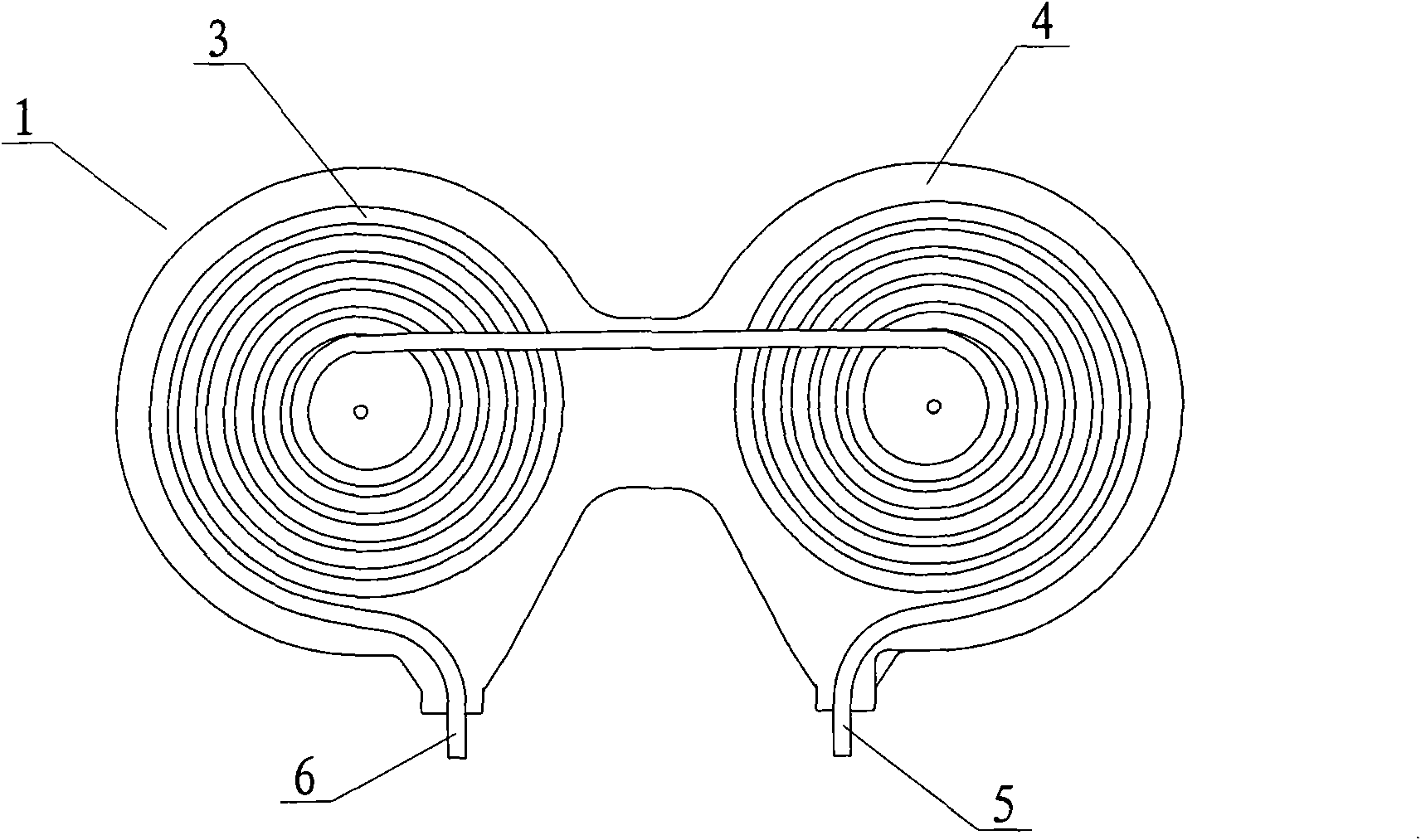

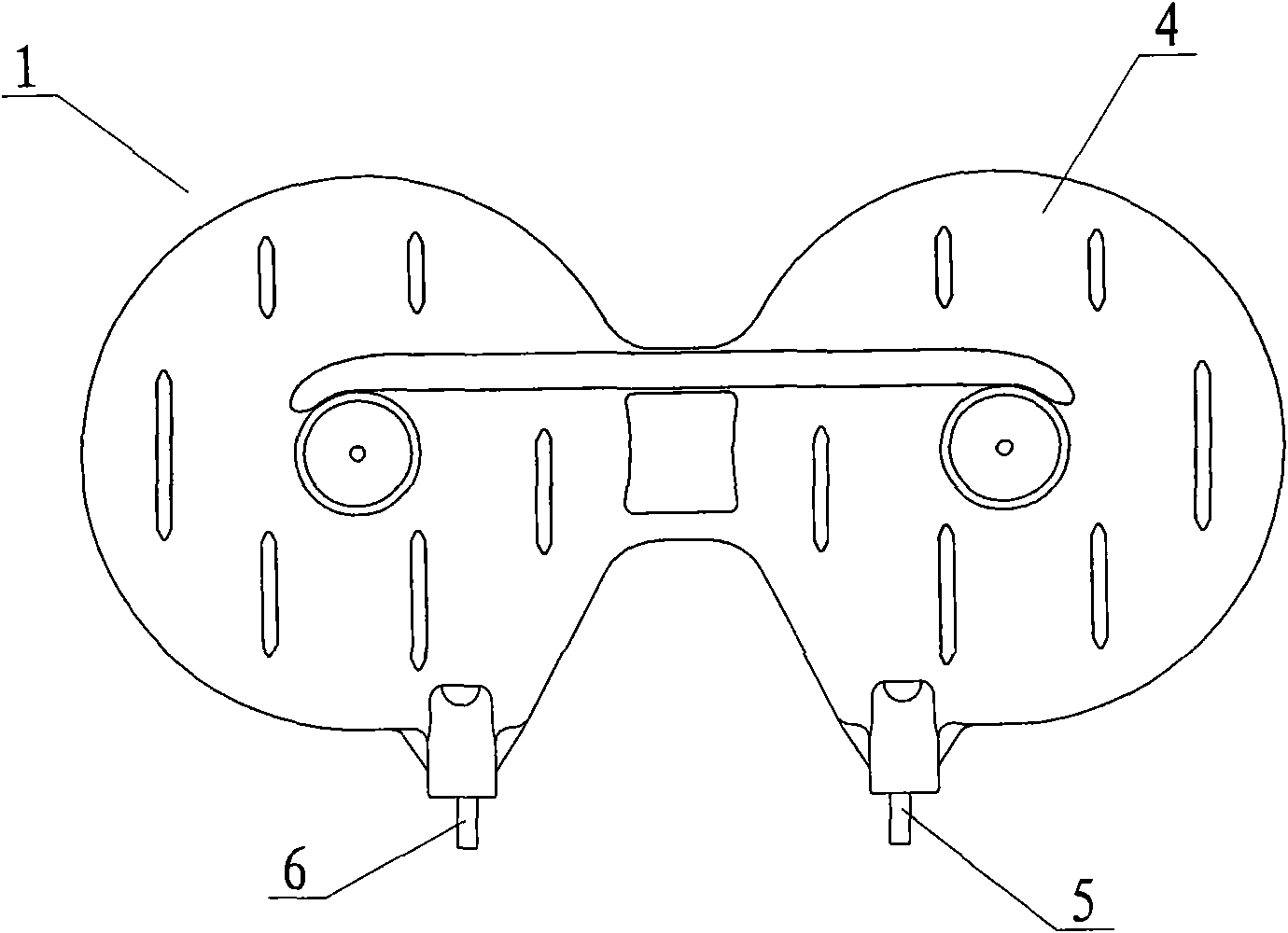

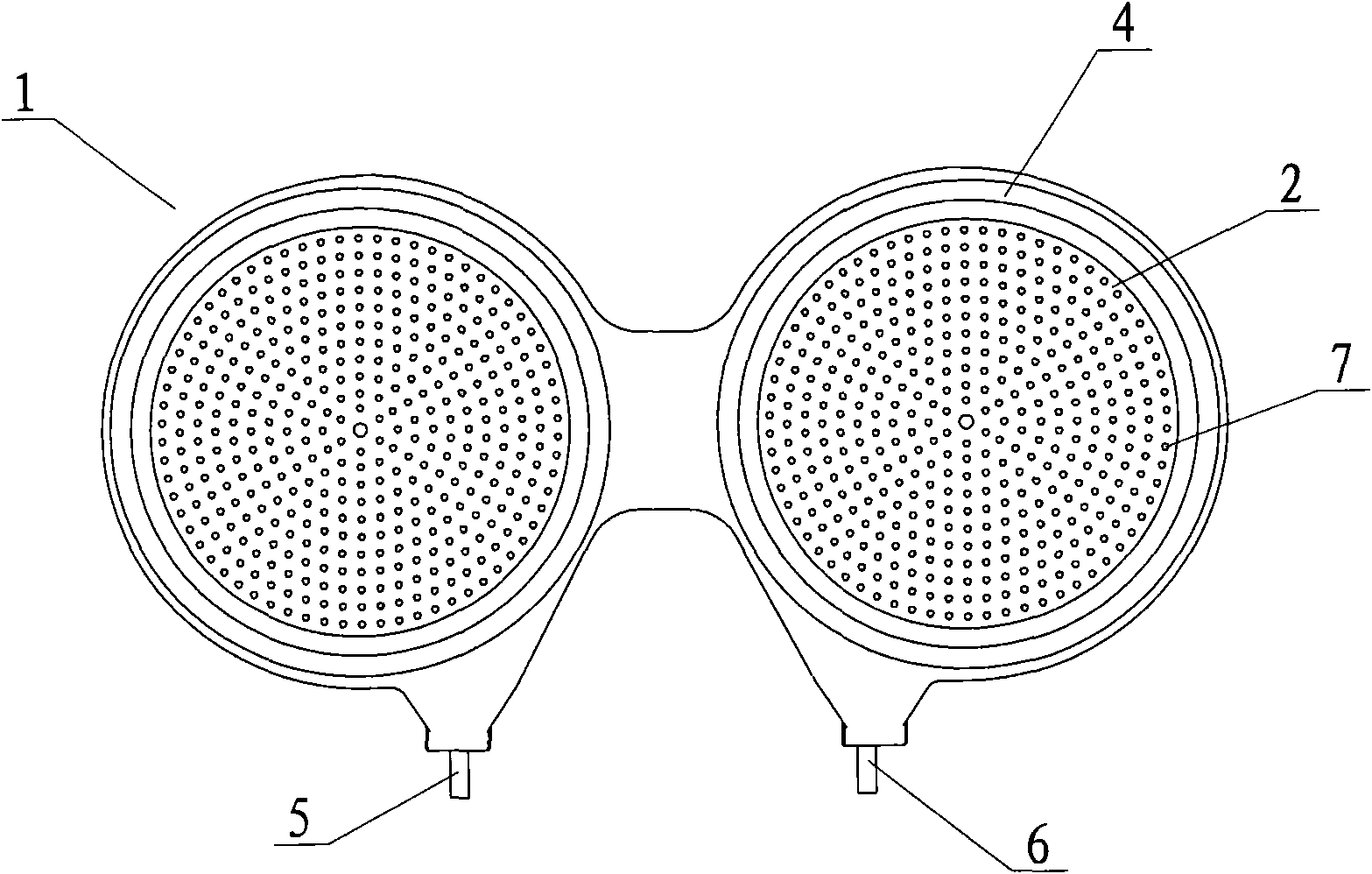

[0025] The linerless electromagnetic water heater of the present invention includes an electromagnetic heating device installed in the casing and an electromagnetic heat conductor 1. The electromagnetic heat conductor 1 includes a heat-conducting metal sheet 2 with holes on the reverse surface and an aluminum or copper body located on the electromagnetic heat conductor. The hollow metal heat pipe 3 with the water inlet 5 and the water outlet 6 inside, because the heat conduction metal sheet 2 has the opening 7, the melted aluminum water or copper water can enter the opening 7, and because the metal heat pipe 3 is completely Immersed in aluminum water or copper water, die-casted and fixed by die-casting equipment, they can be combined together to form an aluminum or copper body 4 with a thermally conductive metal sheet 2 fixed on the reverse side, aluminum wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com