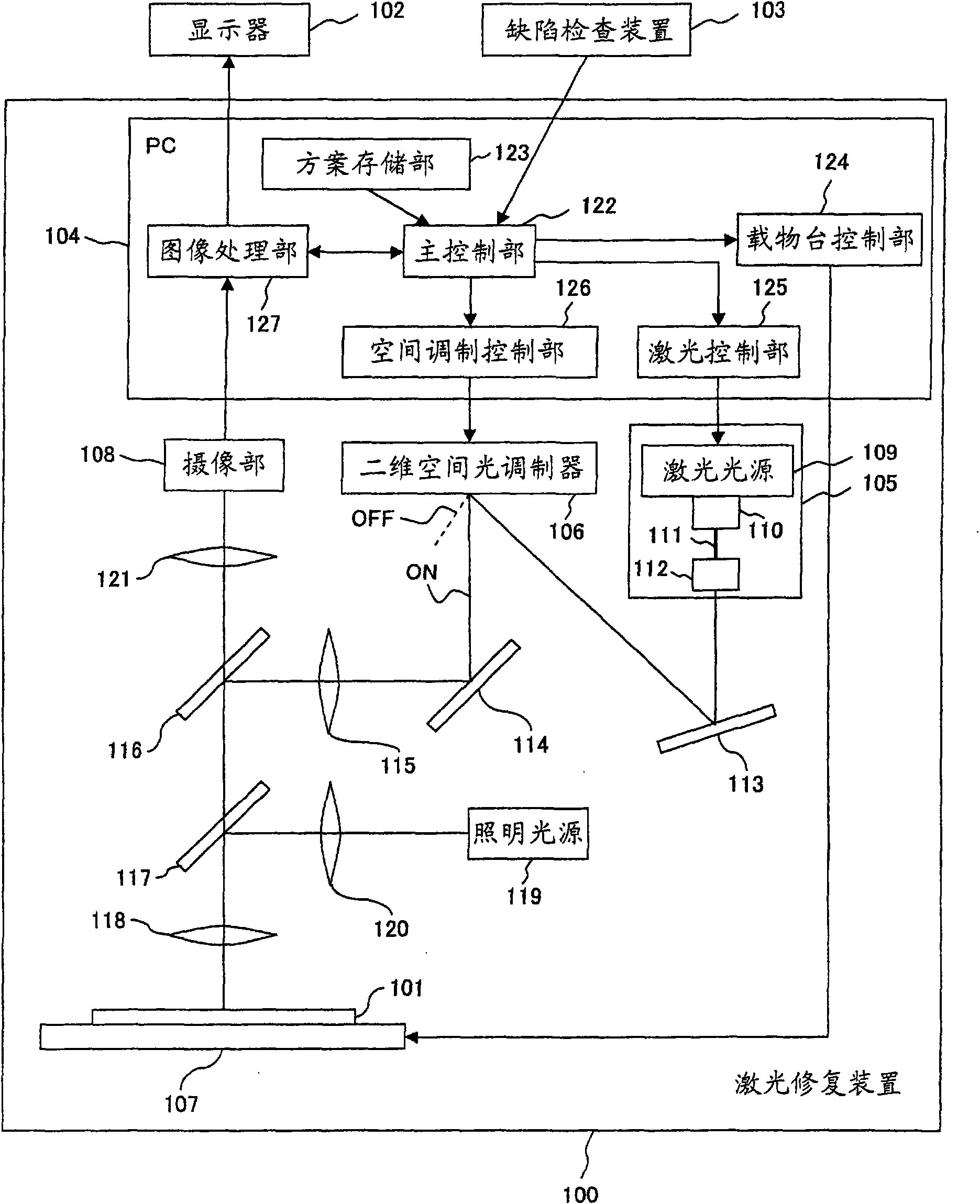

Laser repair device and a laser repair method

A technology of laser repair and laser beam, which is applied in the field of defect repair, and can solve problems such as complex repair and pixel destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

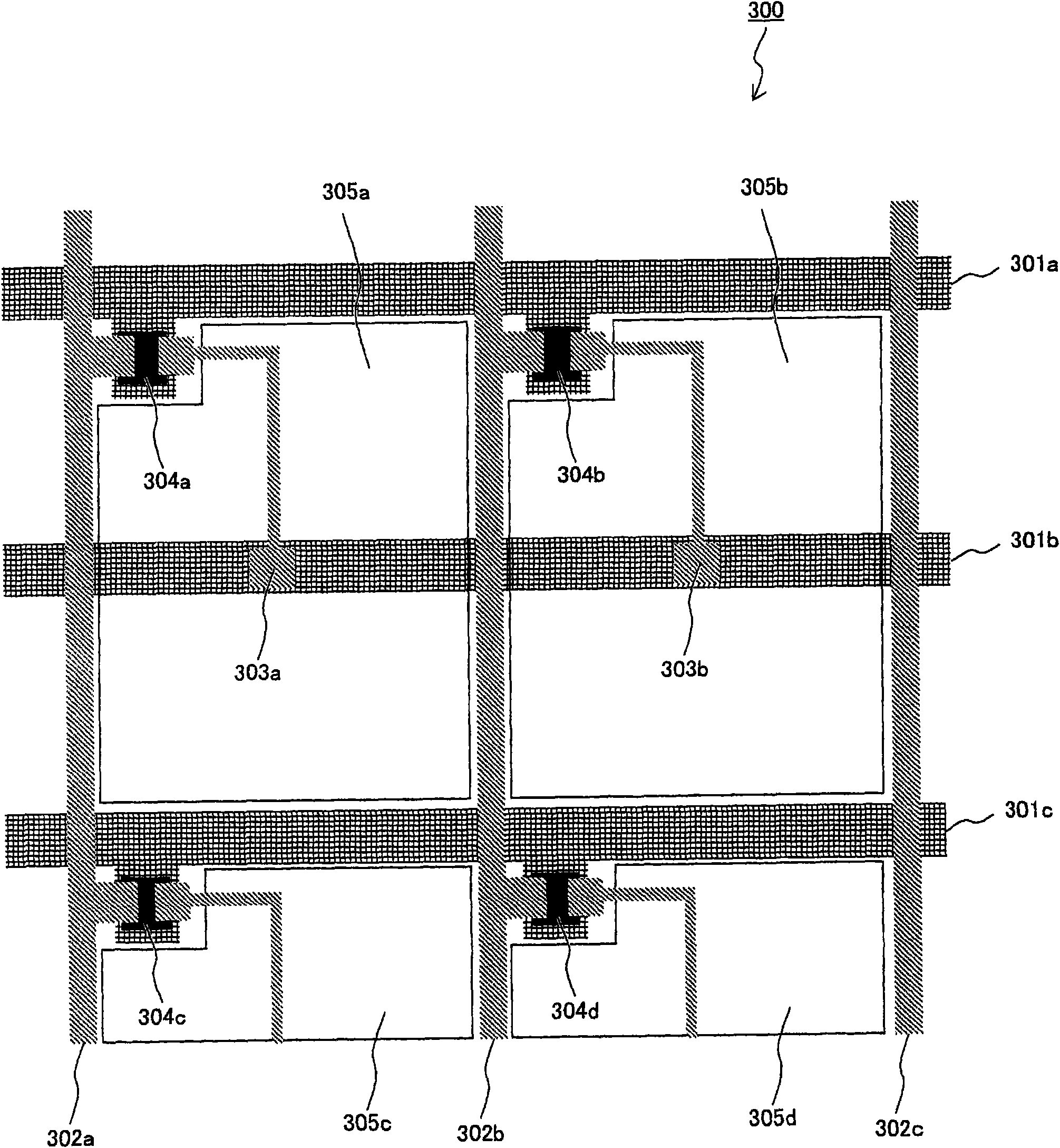

[0037] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

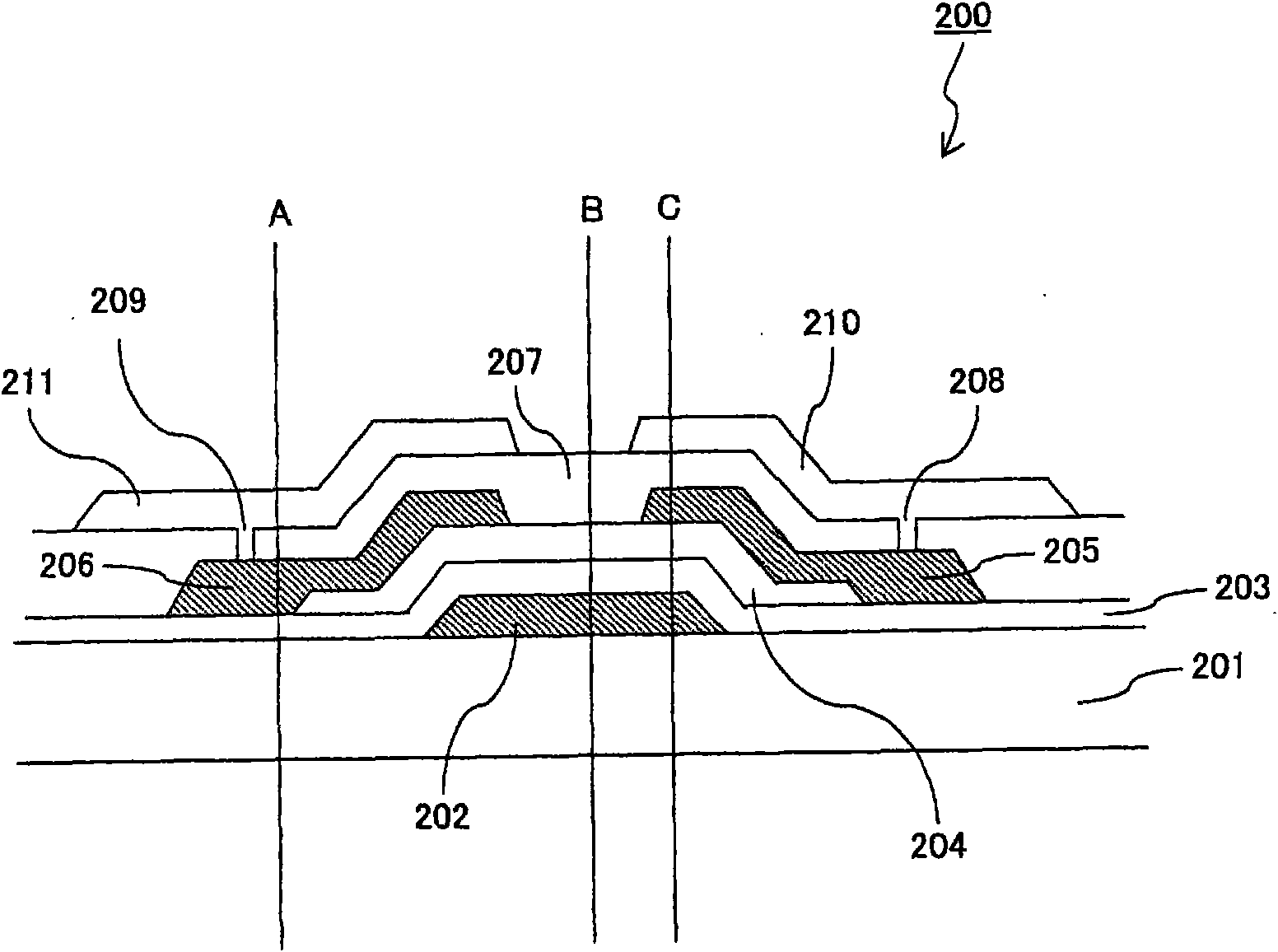

[0038] In addition, in the following embodiment, the term "glass substrate" and "FPD substrate" are differentiated and demonstrated as defined above. That is, a "glass substrate" is a base on which no substance is laminated, and an "FPD substrate" is a product in which various substances are laminated on a glass substrate. Simply referring to "substrate" refers to the glass substrate compared with the FPD substrate as a "product".

[0039] In addition, the "FPD substrate" as a "product" may be a semi-finished product in the middle of each manufacturing process of manufacturing a gate bus layer, an insulating film layer, an amorphous silicon layer, a source / drain bus layer, an insulating film layer, and a transparent electrode layer. , may also be a finished product after the manufacturing of each layer is formed. The object of laser repair in the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com