Solar cell module

A solar cell and sheet technology, applied in photovoltaic modules, photovoltaic modules support structures, circuits, etc., can solve problems such as unsatisfactory decoration, and achieve the effects of excellent decoration, easy configuration, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

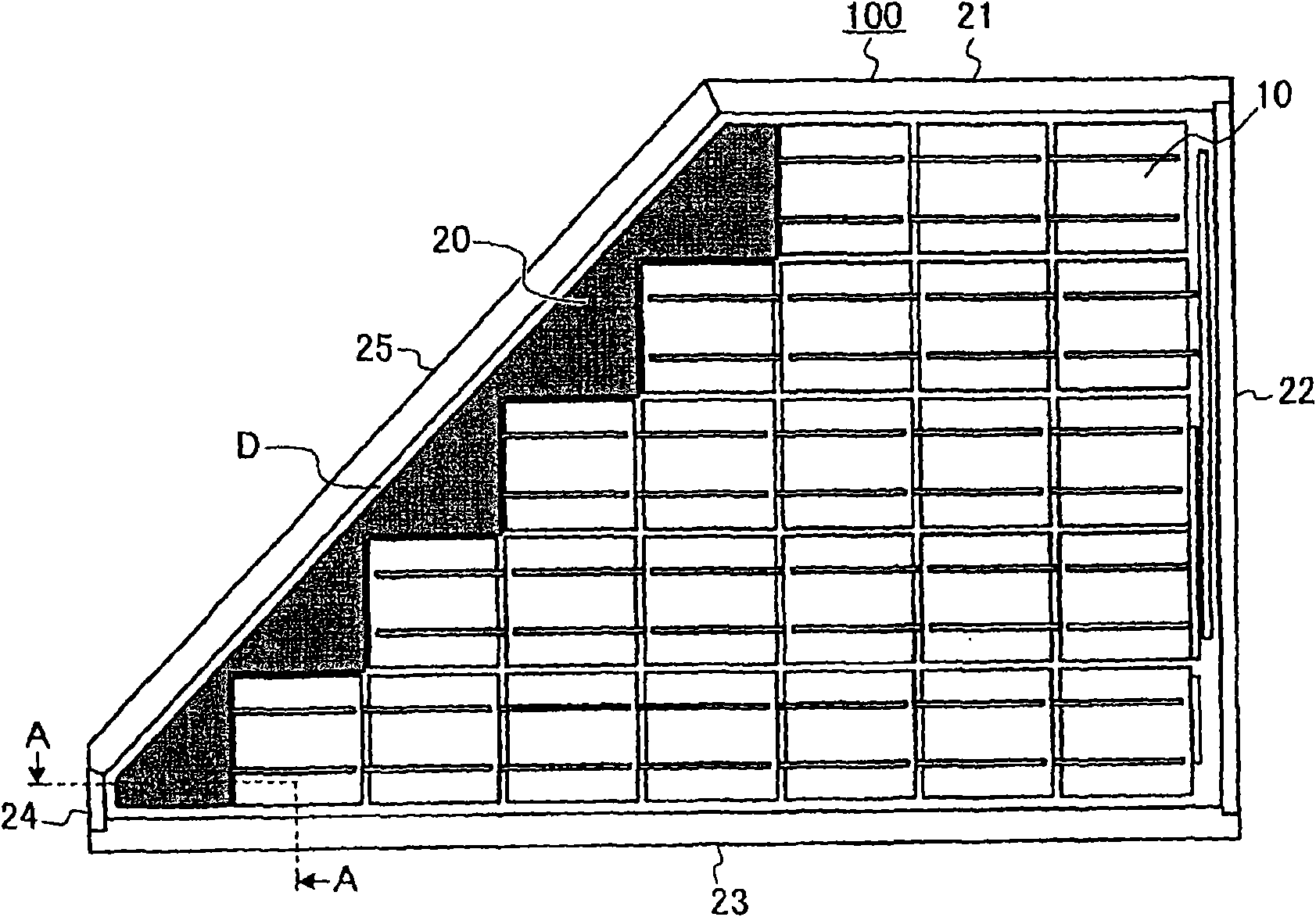

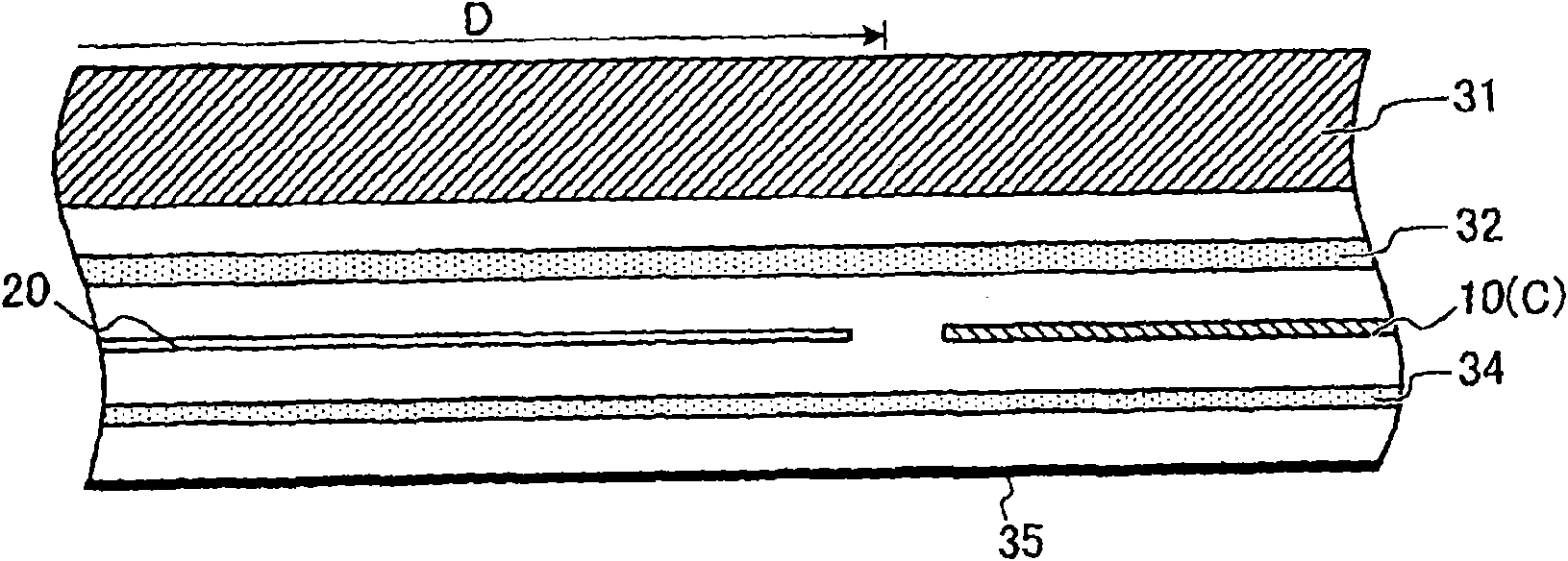

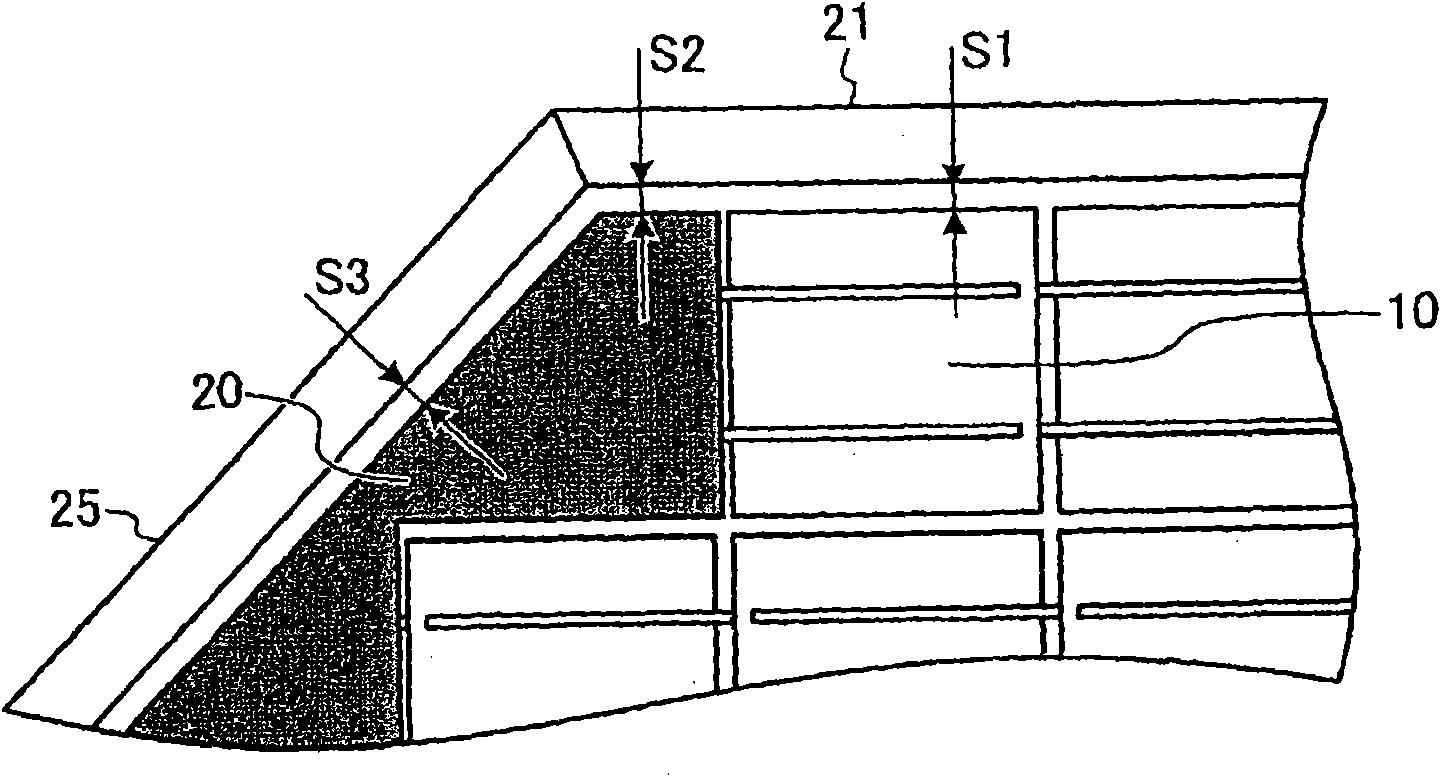

[0025] figure 1 is a front view of an embodiment of a solar cell module according to the present invention. figure 1 Here, the solar cell module 100 shown as an example has a substantially flat trapezoidal shape with one side being a hypotenuse. In addition, the solar battery cells 10 arranged on a plane correspond to the hypotenuse, while extending from figure 1 The lower row and the upper row gradually decrease in number, and the rows are arranged on the one hand. That is, 7 solar battery units 10 are arranged on the first bottom row, 6 solar battery units 10 are arranged on the second row, 5 solar battery units 10 are arranged on the third row, and 5 solar battery units 10 are arranged on the fourth row. Four solar battery cells 10, three solar battery cells 10 are arranged in the fifth row. In addition, since the solar battery cell 10 is formed in a substantially square flat plate shape, the edge of the solar battery cell group on the hypotenuse side is stepped. Theref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com