Optical detecting system and method for classifying solar cells

A solar cell and optical detection technology is applied in the field of optical detection systems for classifying solar cells to achieve the effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

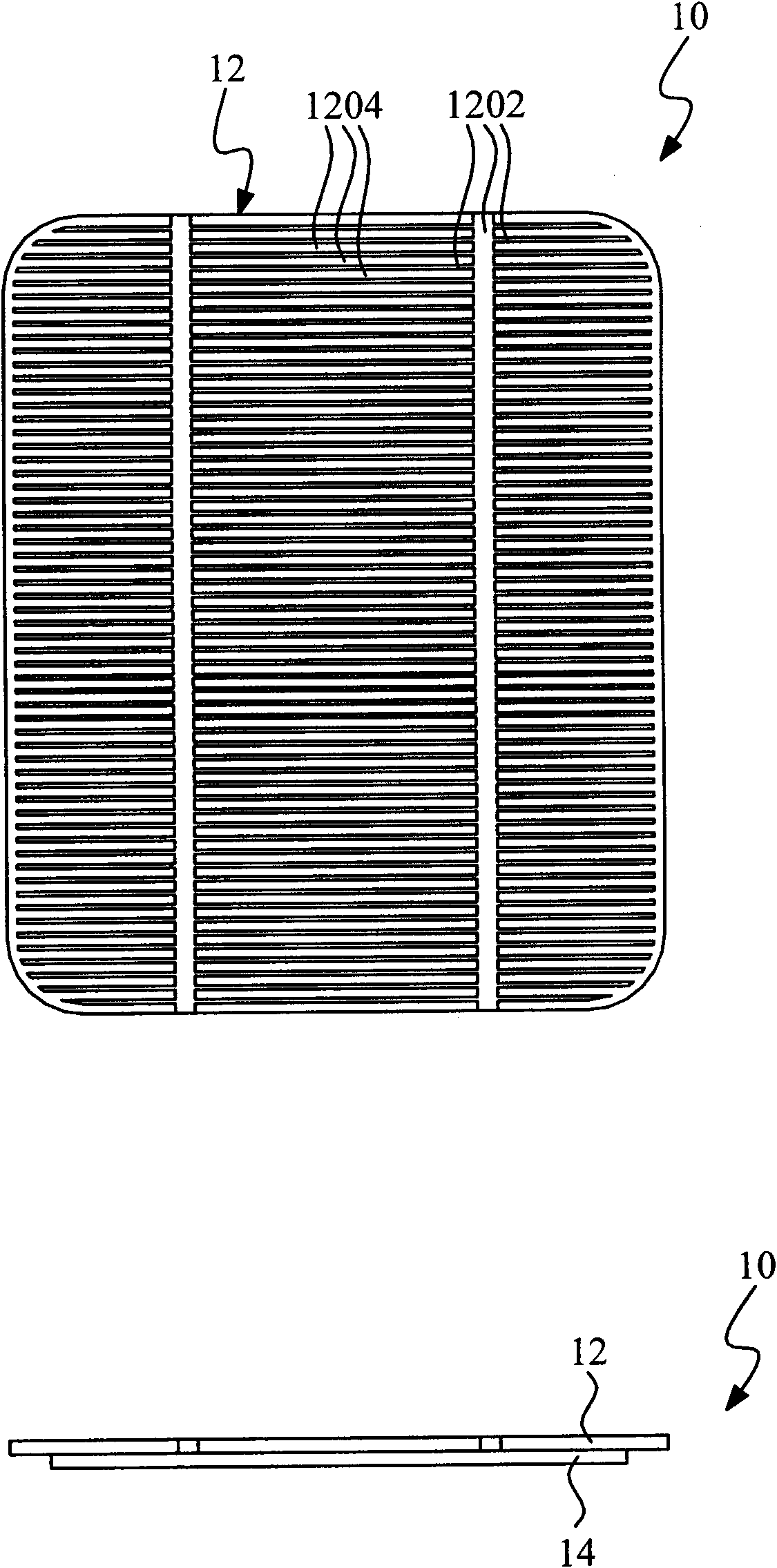

[0034] see figure 1 The appearance and side sectional view of the solar cell 10 in the present invention. It can be seen from the side sectional view that the top and bottom of the solar cell 10 are laminated by a photosensitive layer 12 and an adhesive substrate 14; it can be seen from the front view that the photosensitive layer 12 is viewed from the projection direction, and further includes a wire region 1202 As well as a silicon crystal region 1204 , whether it is polycrystalline silicon or single crystal structure, the color of the silicon crystal region 1204 is often unevenly distributed, and it requires considerable technical means to automatically classify the colors of the solar cells 10 .

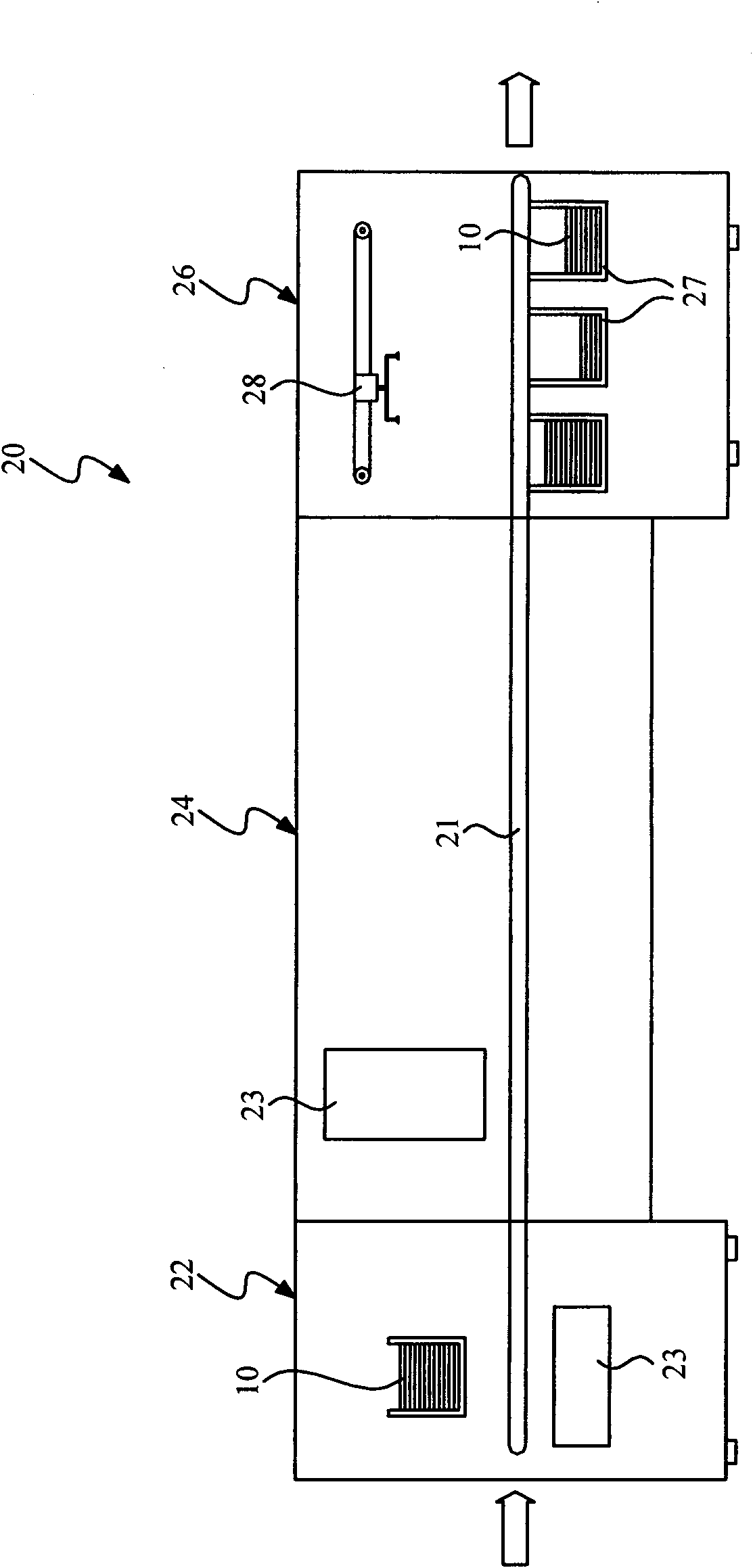

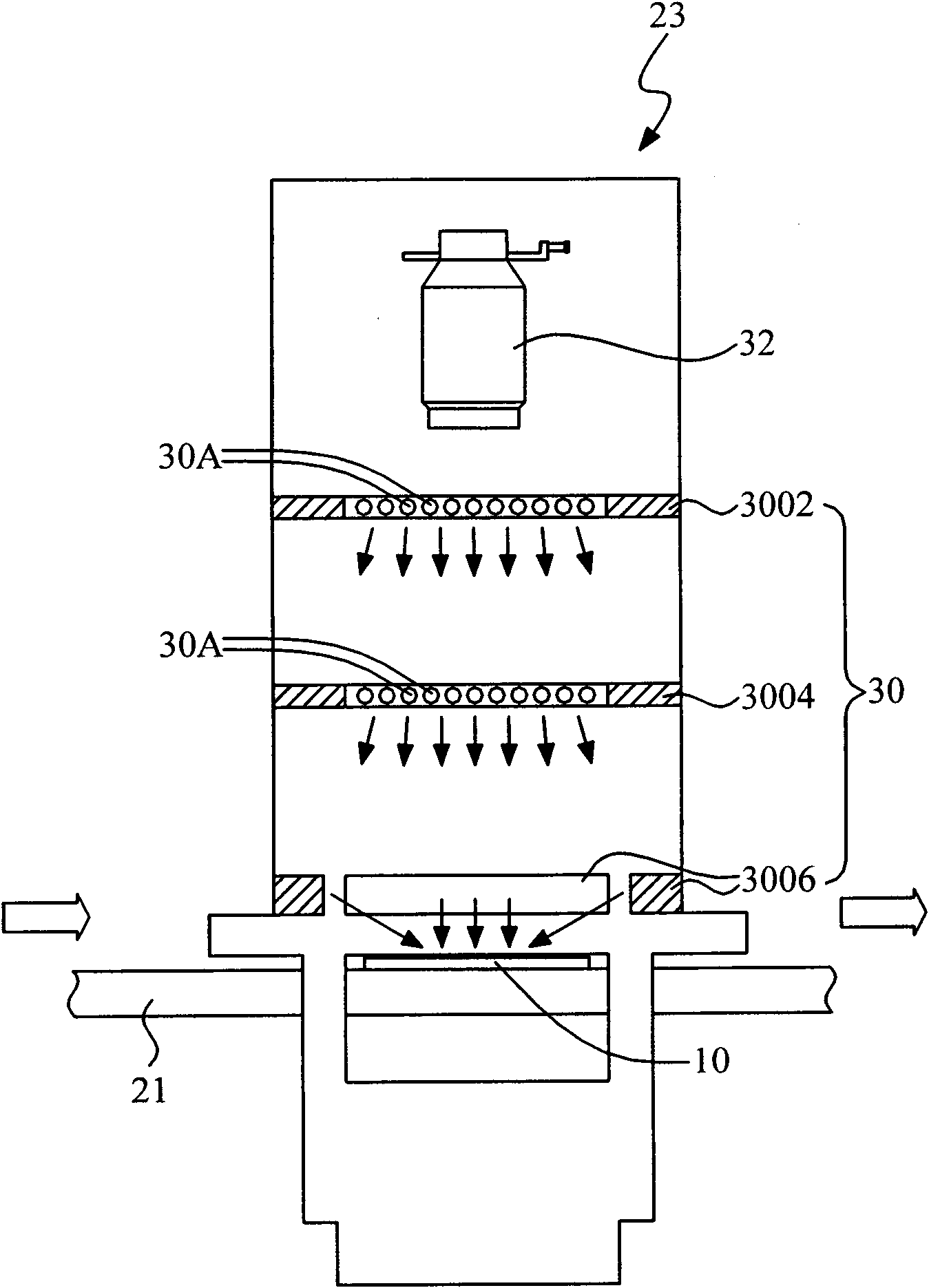

[0035] see figure 2 A schematic diagram of the automatic testing equipment 20 where the optical detection system 23 of the present invention is located. The optical detection system 23 is arranged in an automated testing equipment 20; the front section of the automated testing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com