Liquid crystal panel shift apparatus and method

A liquid crystal panel and transfer device technology, applied in the direction of instruments, chucks, manipulators, etc., can solve the problems of liquid crystal panel 2 damage, increase the tact time of screen acquisition, etc., reduce production costs, improve production efficiency and yield, simplify Effects of complex manipulation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

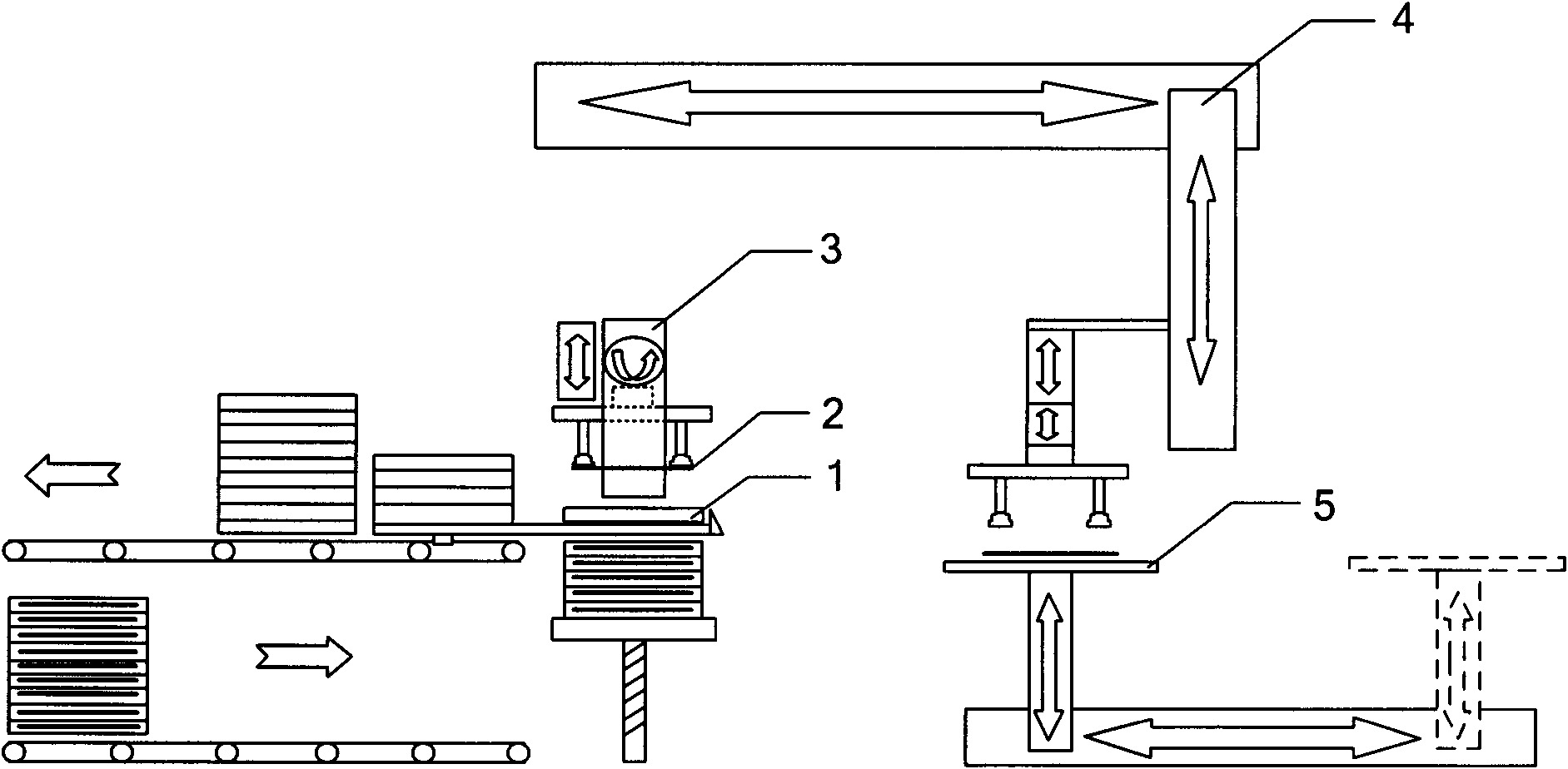

Embodiment 1

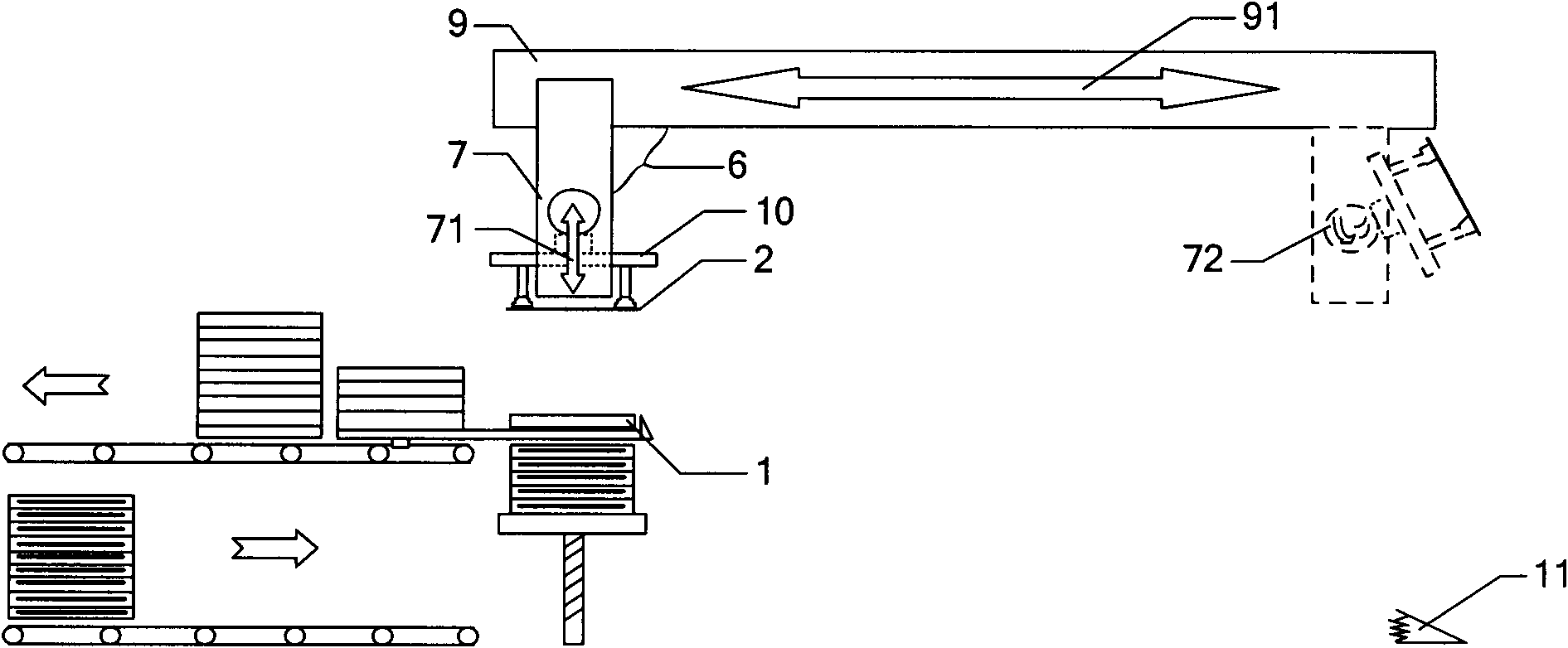

[0028] In the transfer and turning machine 6 included in the above-mentioned liquid crystal panel transfer device for completing the process of absorbing, transporting and rotating the liquid crystal panel to the operating position, as figure 2 As shown, it can specifically include:

[0029] The first piston device 7 comprises a linear cylinder 71, a piston of the linear cylinder 71, a rotary cylinder 72 and a piston of the rotary cylinder 72, and one end of the piston of the rotary cylinder 72 of the first piston device 7 is connected to a liquid crystal panel (Panel) 2 for adsorption. Mechanical arm 10; Wherein, the piston of linear cylinder 71 is connected with rotary cylinder 72, and first piston device 7 is vertically placed with linear cylinder 71 axial direction;

[0030] The second piston device 9 comprises the piston of a linear cylinder 91 and the linear cylinder 91, the second piston device 9 is perpendicular to the first piston device 7, and the piston of the line...

Embodiment 2

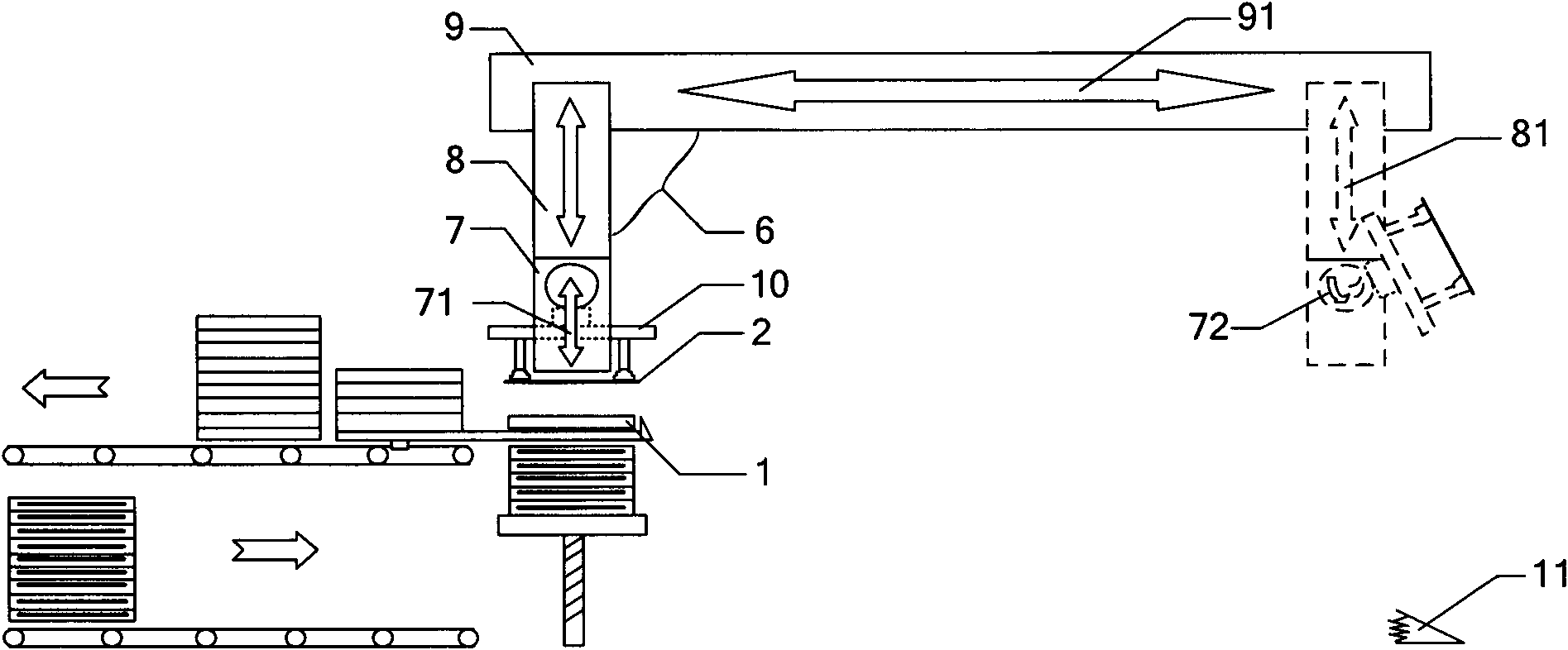

[0037] image 3 It is a structural schematic diagram of another liquid crystal panel transfer device of the present invention. Such as image 3 As shown, the present invention provides another liquid crystal panel transfer device, which differs from the second embodiment above in that a third piston device 8 is added, including a linear cylinder 81 and a piston of the linear cylinder 81 . The setting of the third piston device 8 is for the two transfer and turning machines 6 to reciprocate alternately at two different heights.

[0038] The transfer and turning machine 6 included in the liquid crystal panel transfer device for completing the process of absorbing, transporting and rotating the liquid crystal panel to the operating position can also specifically include:

[0039] The first piston device 7 comprises a linear cylinder 71, a piston of the linear cylinder 71, a rotary cylinder 72 and a piston of the rotary cylinder 72, and one end of the piston of the rotary cylind...

Embodiment 3

[0048] Figure 4 It is a flow chart of the liquid crystal panel transfer method of the present invention. Such as figure 2 , Figure 4 As shown, the specific steps include:

[0049] Step 401, absorbing the horizontally placed liquid crystal panel and moving it up to the first height position;

[0050] Specifically, the piston of the linear cylinder 71 of the first piston device 7 is located at the lower end of the linear cylinder 71, and the mechanical arm 10 connected to the piston of the rotary cylinder 72 of the first piston device 7 vacuum-adsorbs the liquid crystal panel (Panel) 2, wherein the linear cylinder The piston of 71 is connected with rotary cylinder 72, and the piston of the linear cylinder 71 of the first piston device 7 moves to the upper end of the linear cylinder 71, and the mechanical arm 10 also moves to the first height position along with the piston of the linear cylinder 71.

[0051] Step 402, moving the liquid crystal panel horizontally;

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com