Surface protective film

A technology for protecting film and adhesive layer, applied in the direction of film/sheet adhesive, thin material handling, adhesive type, etc., to achieve the effect of improving unwinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

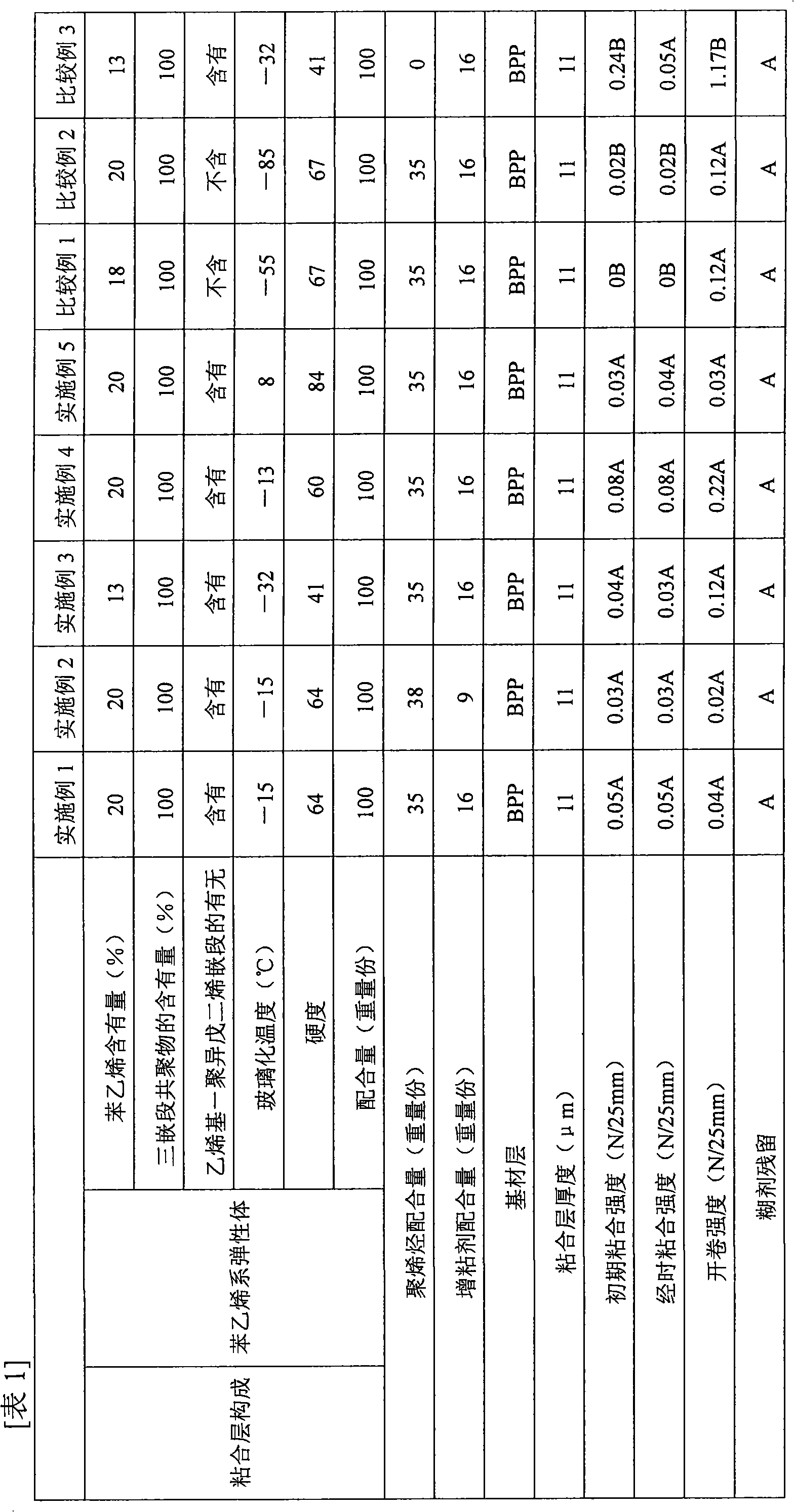

Embodiment 1

[0097]A styrene-based elastomer containing a vinyl-polyisoprene block (Kuraray manufactured by the company, trade name HYBRAR7125) 100 parts by weight, RPP (manufactured by Japan Polypro Corporation, trade name WFW-4) 35 parts by weight, tackifier (Idemitsu Kosan, trade name IMARV P-140) 16 parts by weight as polyolefin parts by weight, as the adhesive layer material.

[0098] This adhesive layer material was co-extruded with BPP (manufactured by SunAllomer, trade name PC-684S) as a substrate layer material by a two-layer co-extrusion method so that the thickness of the adhesive layer was 11 μm and the thickness of the substrate layer was 39 μm. Surface protection film.

Embodiment 2

[0100] Except having changed the compounding quantity of polyolefin into 38 weight part, and the compounding quantity of a tackifier into 9 weight part, it carried out similarly to Example 1, and obtained the surface protection film.

Embodiment 3

[0102] The styrene-based elastomer was changed to a styrene-based vinyl-polyisoprene block containing 13% styrene, 100% triblock copolymer, and a glass transition temperature of -32°C. A ethylene-based elastomer (manufactured by Kuraray Corporation, trade name HYBRAR7311) was carried out in the same manner as in Example 1 except that, to obtain a surface protection film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com