Armature stroke adjustment for solenoid valve

A solenoid valve and armature technology, which is applied to fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as sensitive tolerances and long distances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

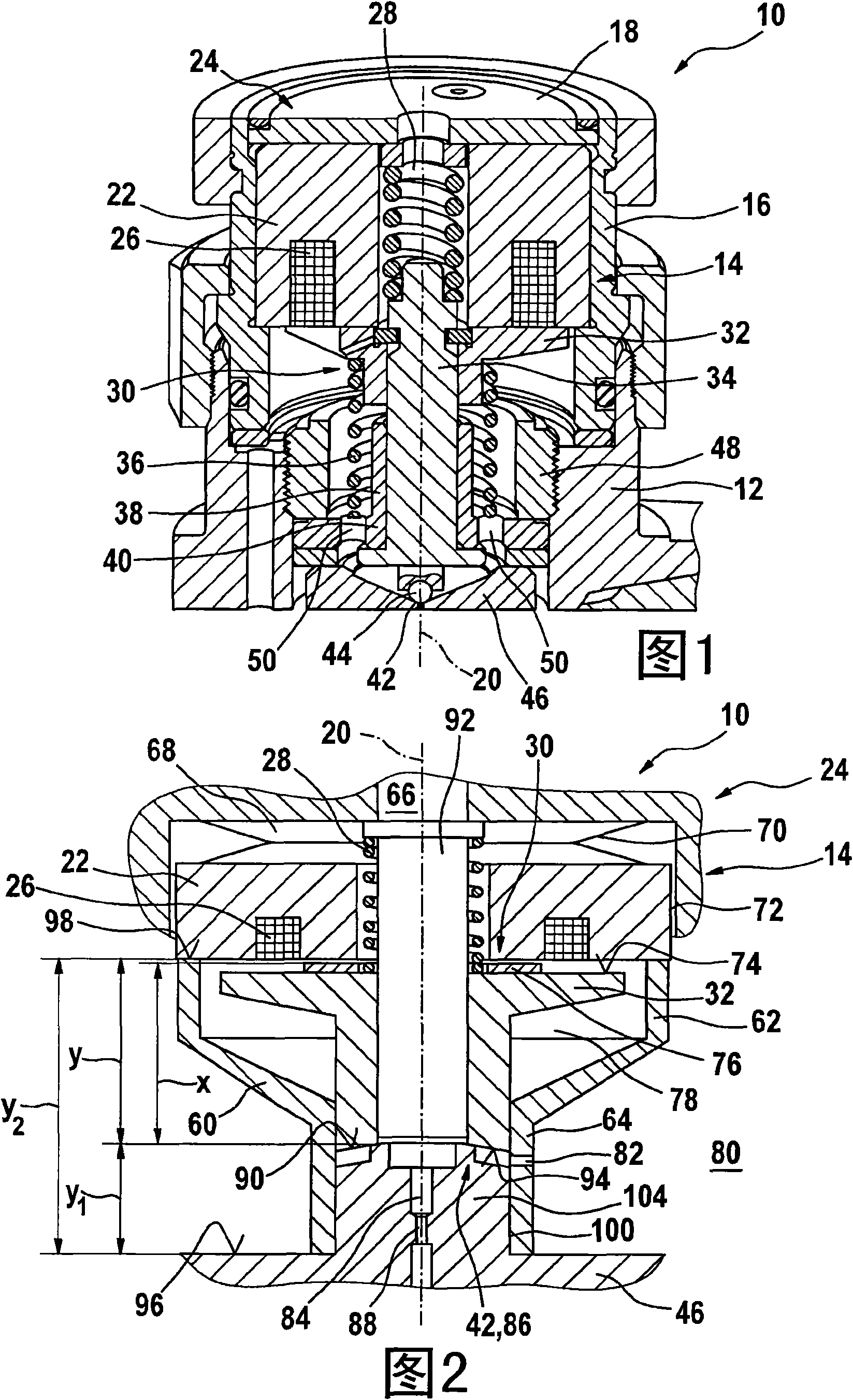

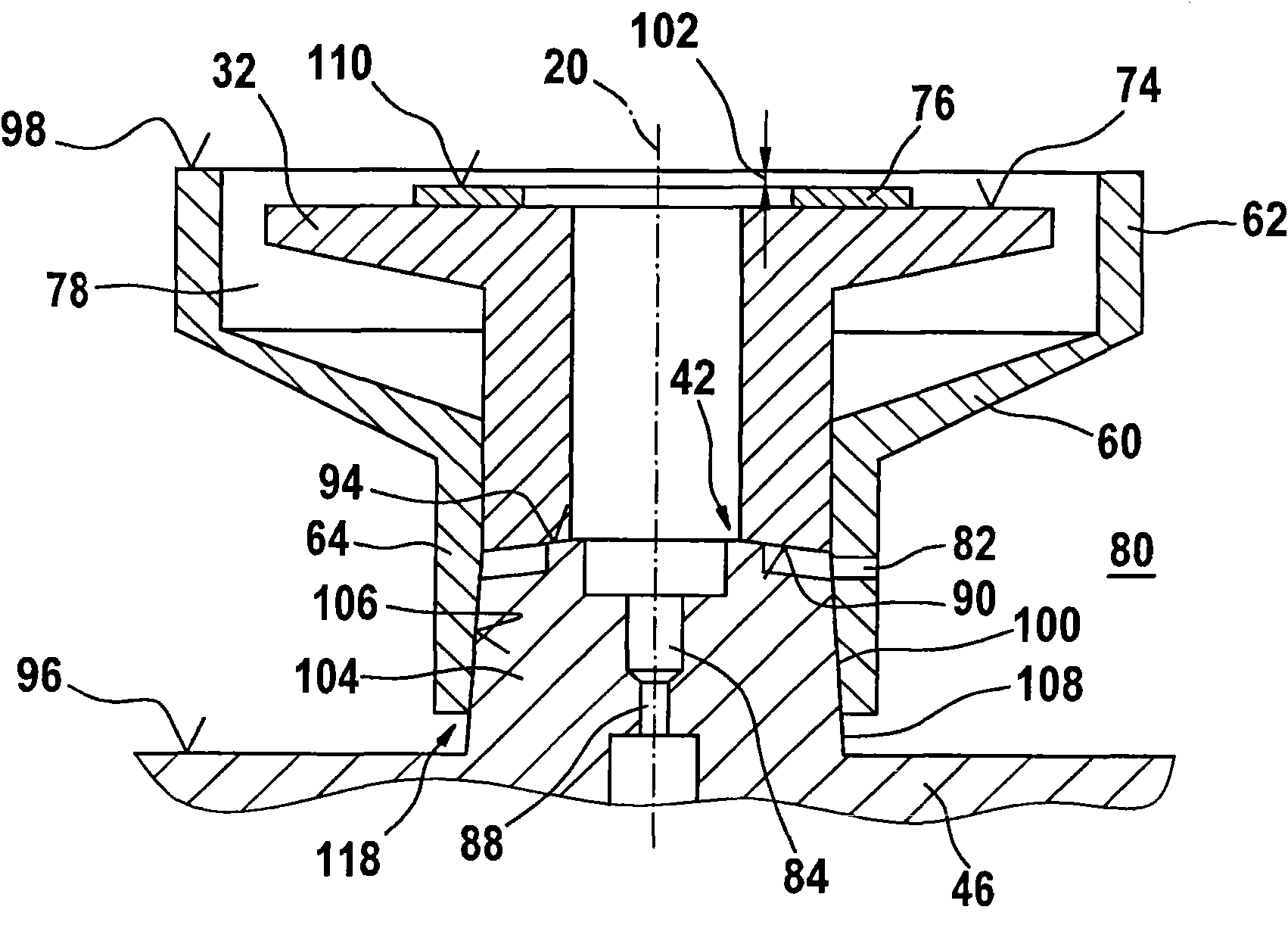

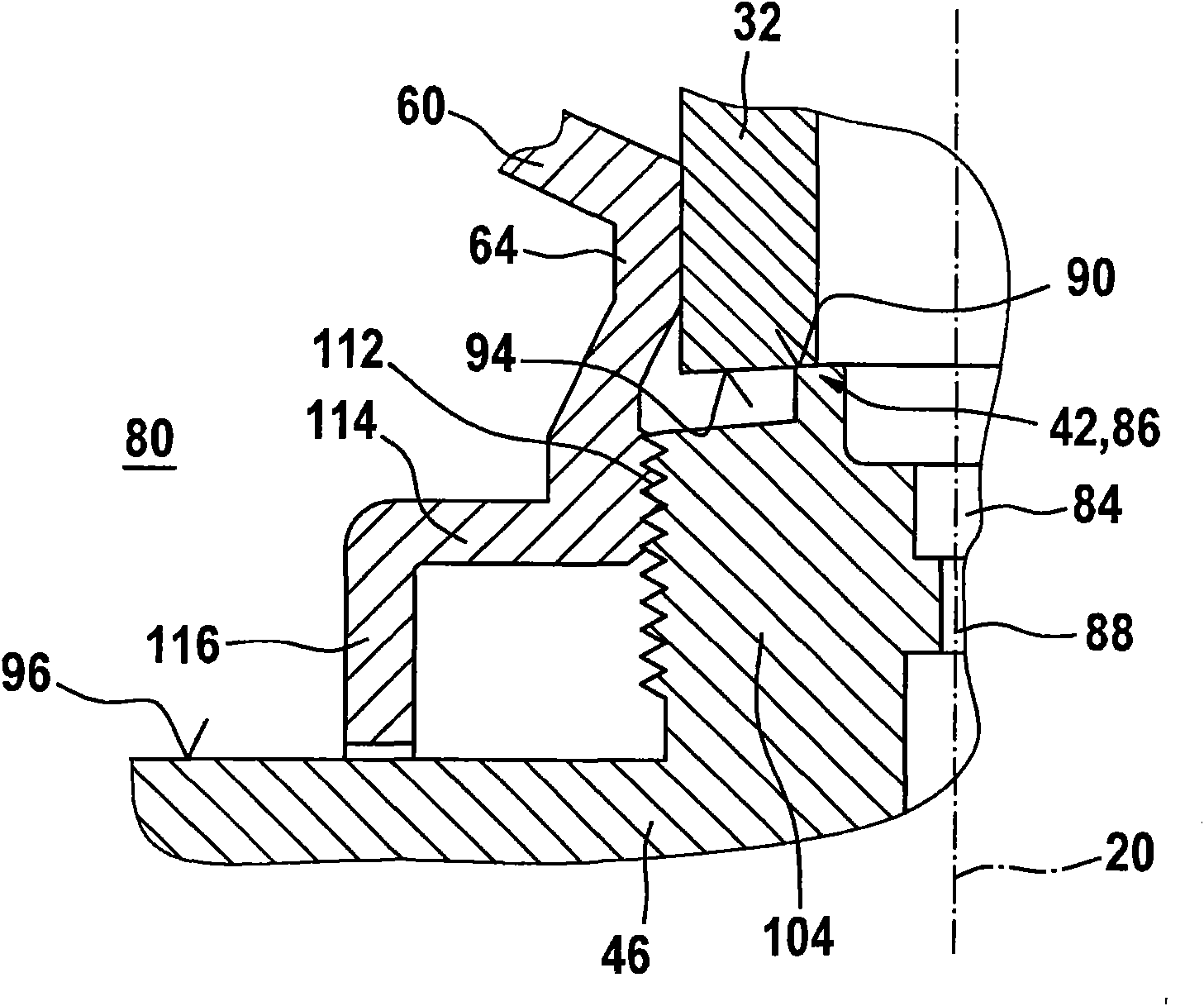

[0022] from according to figure 1 A solenoid valve according to the prior art is known from the diagram of FIG.

[0023] according to figure 1 The fuel injector 10 shown in the figure comprises a holding body 12 in which a solenoid valve 14 is received. The solenoid valve 14 is surrounded by a sleeve 16 which is closed by a cover 18 which can be fastened to the sleeve 16 with nuts or the like. according to figure 1 In the illustration in , the solenoid valve 14 is configured symmetrically with respect to the axis 20 .

[0024] The solenoid valve 14 includes a magnetic core 22 that receives a return spring 28 . Furthermore, a solenoid coil 26 is embedded in the magnetic core 22 of the solenoid valve 14 . The armature plate 32 of the armature assembly 30 is opposite the lower end side of the magnetic core 22 . The armature plate 32 of the armature assembly 30 is loaded by the return spring 28 . from according to figure 1 It can also be seen from the diagram that, accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com