Method for separating a mixture of carbon monoxide, methane, hydrogen, and optionally nitrogen by cryogenic distillation

A carbon monoxide and mixture technology, applied in the directions of carbon monoxide, cold treatment separation, liquefaction, etc., can solve the problems of inability to cool, low evaporation temperature, etc., and achieve the effect of saving energy, cost/investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

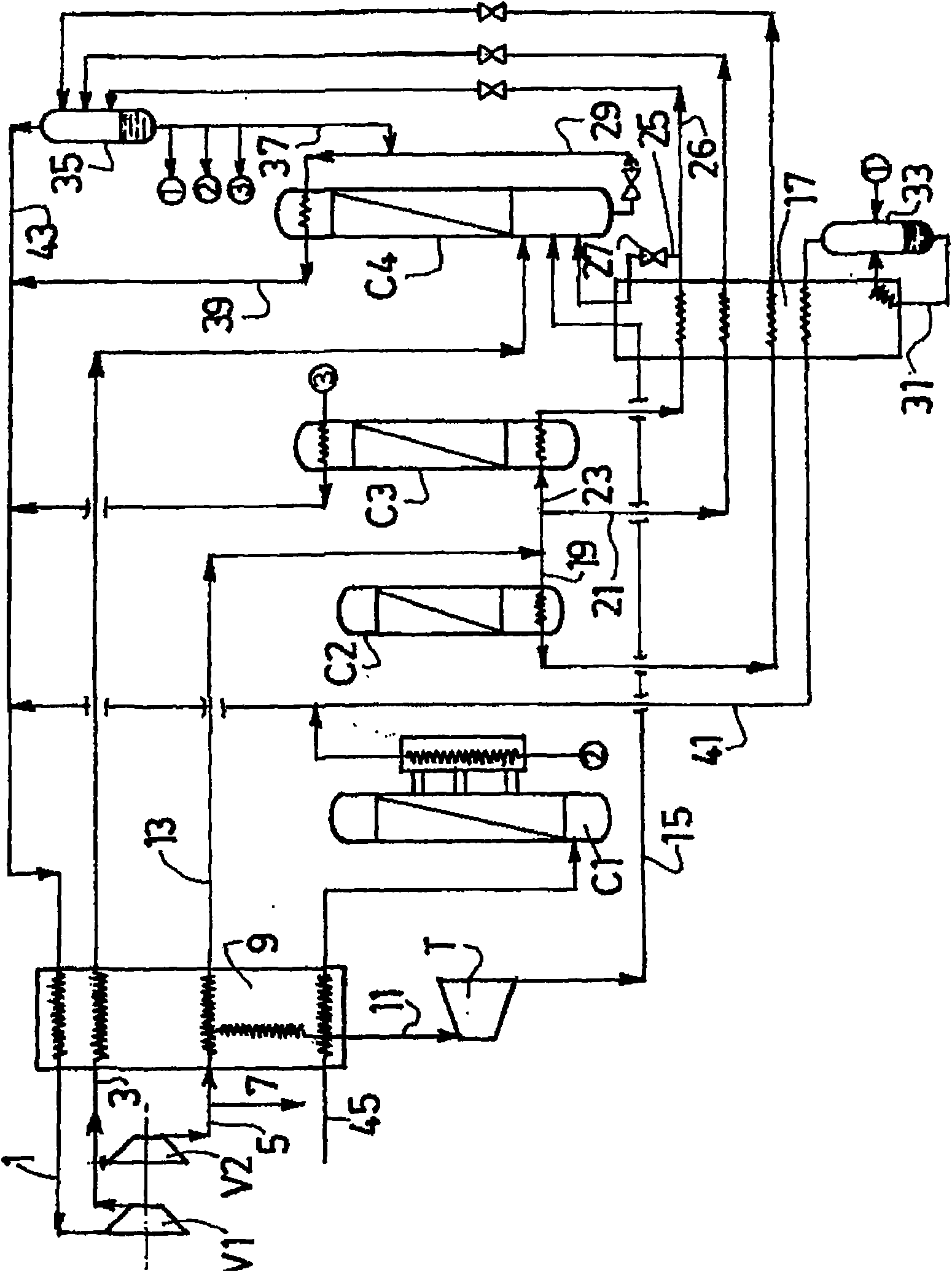

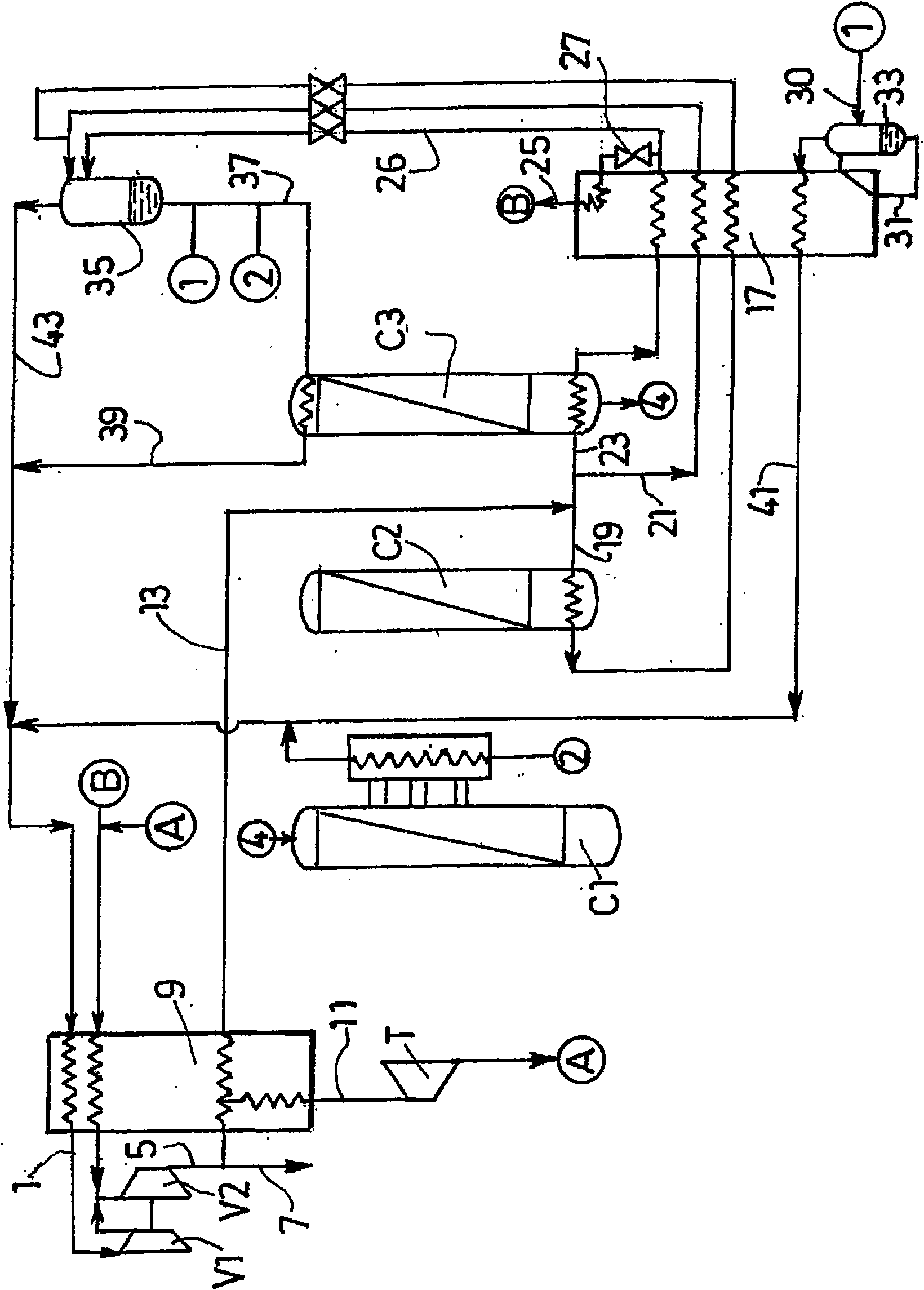

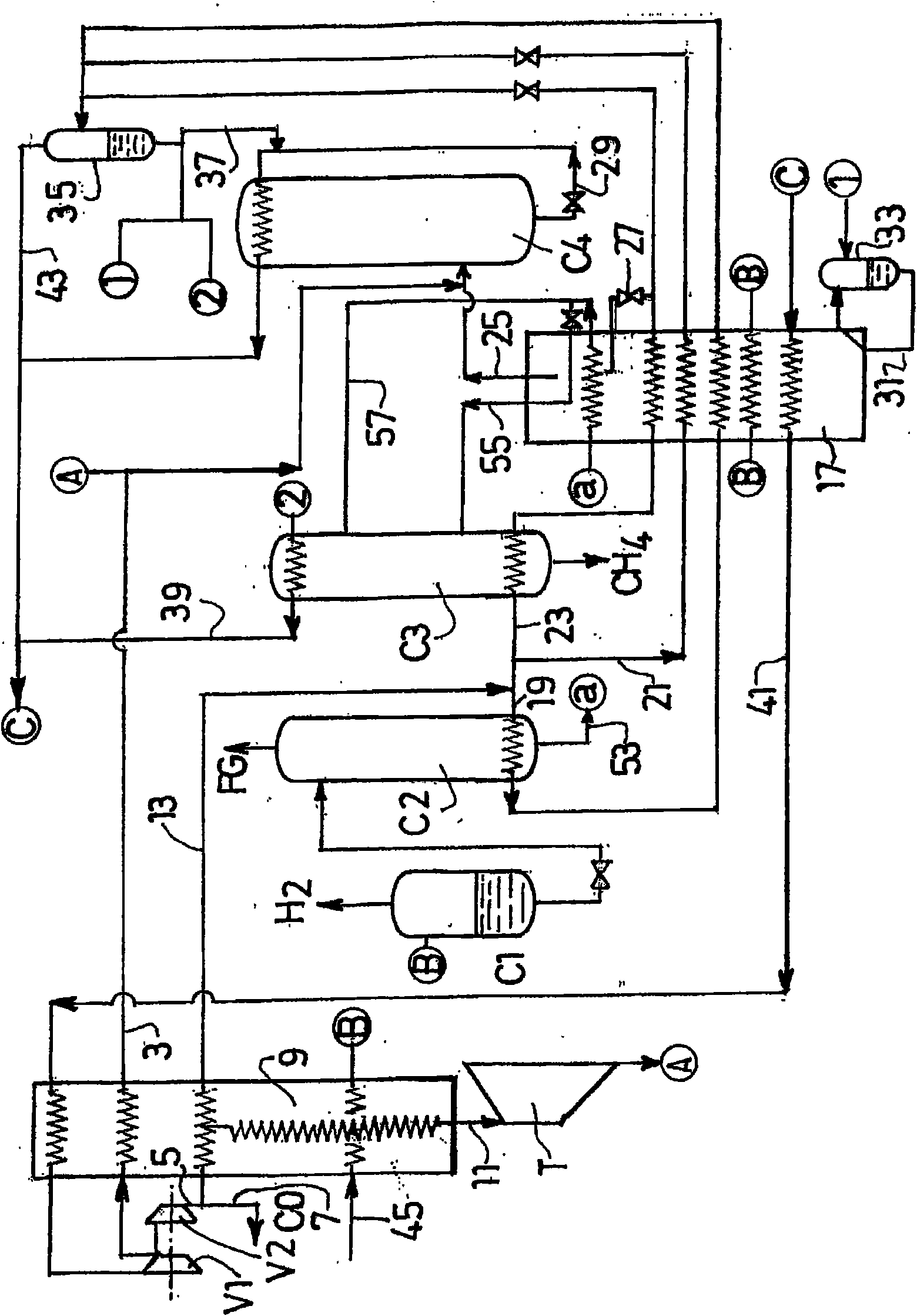

[0067] To simplify the attached figure 1 , only the inlet for the gas to be treated and the carbon monoxide cycle are shown.

[0068] Stream 45 comprising carbon monoxide, hydrogen, methane and nitrogen is cooled in exchanger 9 by heat exchange with carbon monoxide stream 1 and is sent to methane scrubber C1 which is fed at the top with very low temperature liquid methane stream.

[0069] However, it should be understood (although not shown) that liquid from the bottom of column C1 is sent to the top of stripping column C2. The hydrogen-rich gas from the top of column C1 leaves the plant. Liquid from the bottom of stripper C2 is sent to CO / CH 4 Separation column C3. Liquid from the bottom of column C3 is sent back to the top of column C1. Gas from the top of column C3 is sent to an intermediate position in denitrogenation column C4 where it is separated into a carbon monoxide-rich bottom liquid and nitrogen-rich overhead gas. The column arrangement is thus consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com