Laminate and solar battery using the laminate

A technology of solar cells and laminates, applied in the field of dye-sensitized solar cells, which can solve the problems of expensive microwave irradiation devices, easy deterioration of resin substrates, and difficulty in manufacturing batteries, and achieve good long-term stability, safety and durability , the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

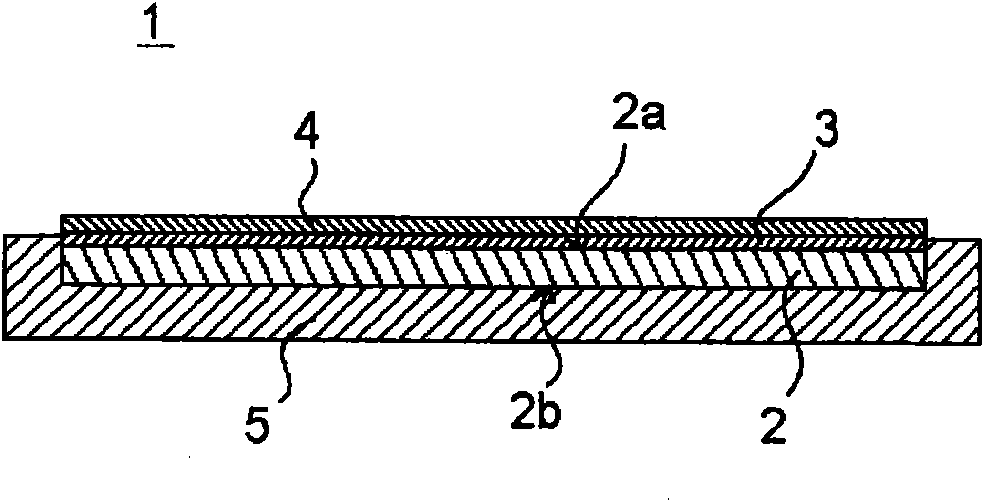

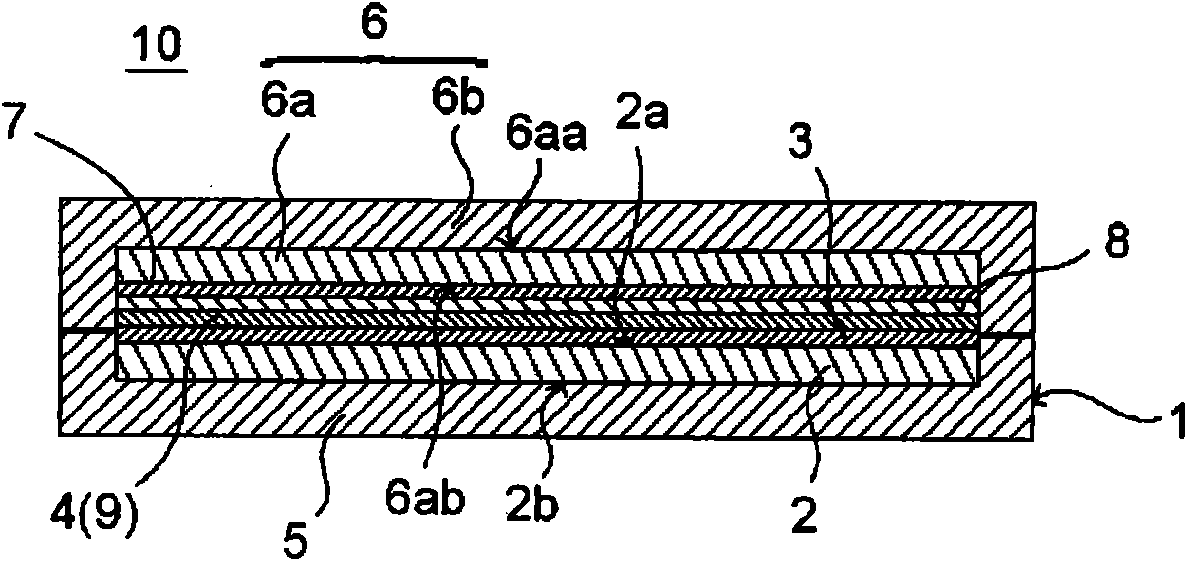

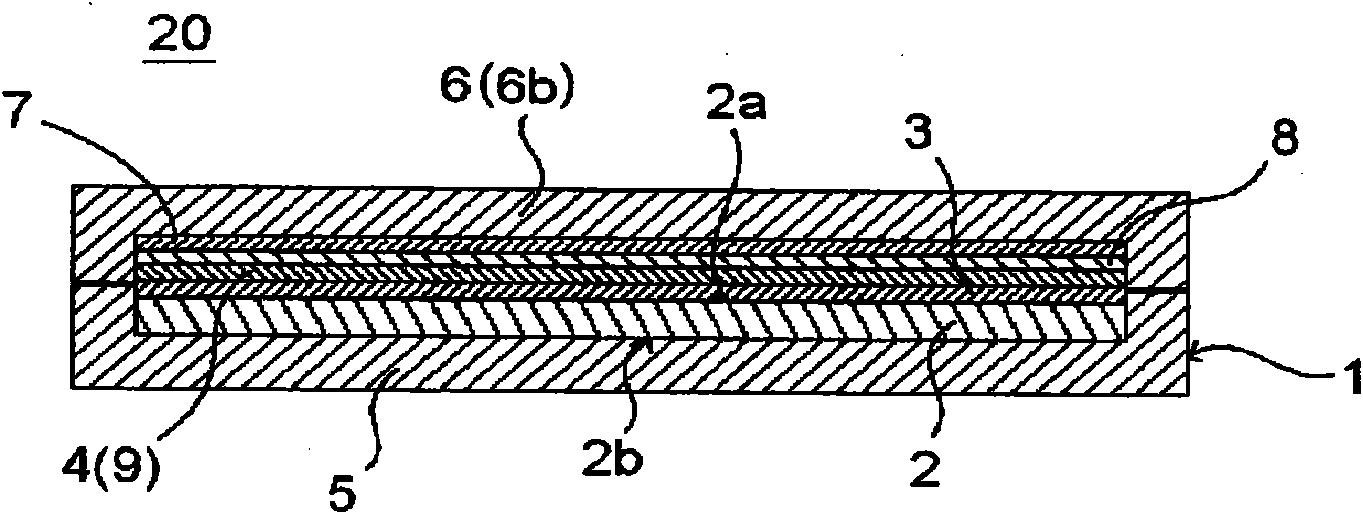

[0059] Next, embodiments of the present invention will be described based on the drawings and tables. figure 1 It is an explanatory drawing of the laminated body of this invention, figure 2 It is an explanatory diagram of the dye-sensitized solar cell of the present invention. image 3 It is an explanatory diagram of another dye-sensitized solar cell of the present invention. Table 1 shows Examples 1-5 of the present invention, Table 2 shows Examples 6-8, Table 3 shows Examples 9-12, and Table 4 shows Comparative Examples 1-3.

[0060] Table 1

[0061]

[0062] Table 2

[0063]

[0064] table 3

[0065]

[0066] Table 4

[0067]

[0068] Such as figure 1 As shown, the laminated body 1 of Examples 1 to 5 and Comparative Examples 1 and 2 includes a first glass plate 2 having a first surface 2 a and a second surface 2 b, and a conductive material formed on the first surface 2 a of the first glass plate 2 . The film 3 , the photoactive layer 4 formed on the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com