Wafer level capsulation mechanism and wafer level capsulation method used for radio-frequency micro electromechanical system

A micro-electromechanical system and wafer-level packaging technology, which is applied in the direction of microstructure technology, microstructure devices, processing microstructure devices, etc., can solve the problems of high price and need for drilling technology, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

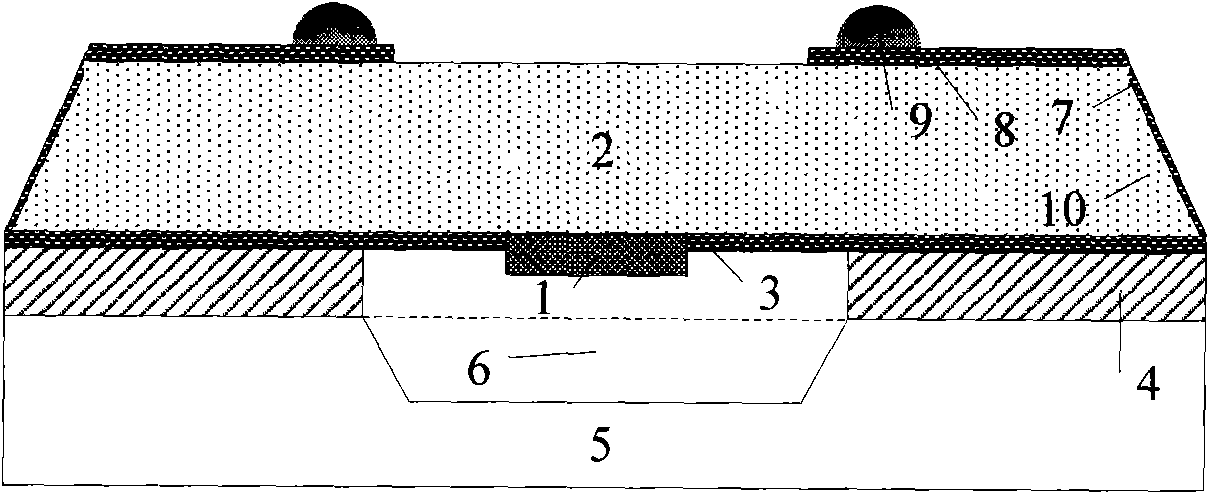

[0017] see figure 1 , RF MEMS devices 1 and signal transmission lines 3 are arranged on the substrate 2; the substrate 2 is press-welded together with the top cover material 5 through the sealing material 4; there are bevels 10 around the substrate 2, the signal transmission lines 3 and the side wall leads 7 is laid on the bevel 10 and is further connected with the package top lead 8 to the solder ball 9 .

[0018] If the thickness of the sealing material 4 is less than 40 um, the top cover material 5 is provided with a cavity 6 .

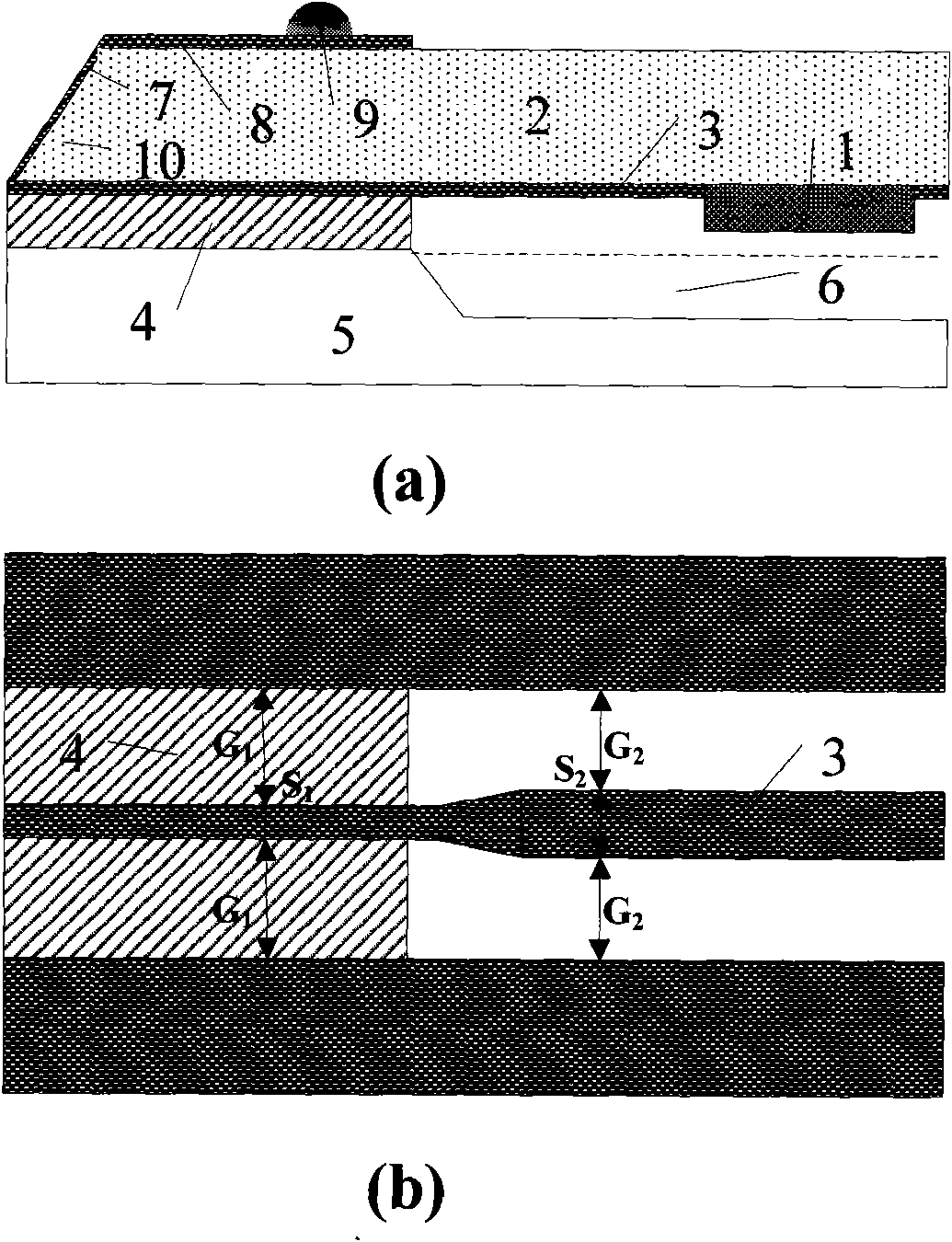

[0019] see figure 2 , the signal transmission line 3 on the top cover material 5 reduces the impact by corroding the cavity 6 in the top cover material 5; if the signal transmission line 3 on the sealing material 4 is not long, that is, less than 200 microns, it does not need to be redesigned, if it is determined If t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com