Method for pre-conditioning and stabilizing an etching chamber and method for cleaning an etching chamber

一种预处理、蚀刻的技术,应用在工艺腔室的清洁领域,能够解决清洁晶片批平均时间增加暴露工艺腔室损坏、制造成本及时间增加、关键尺寸变异等问题,达到减少头片晶片效应、减少平均时间、改进变化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will provide many different embodiments to implement different features of the present invention. The composition and configuration of each specific embodiment will be described below to simplify the present invention. These examples are not intended to limit the present invention. In various examples in this specification, repeated reference numerals may appear to simplify the description, but this does not mean that there is any specific relationship between the various embodiments and / or the drawings.

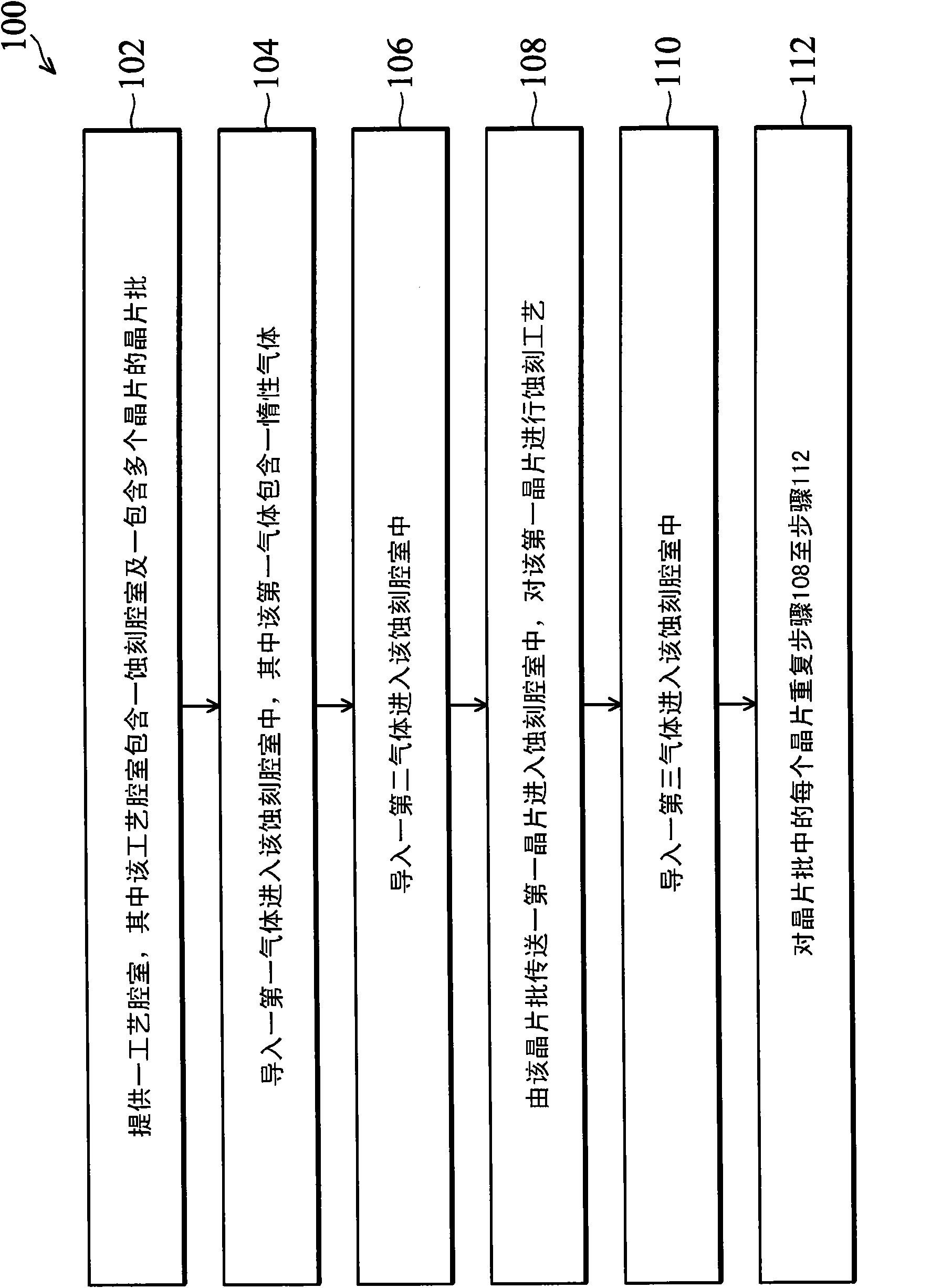

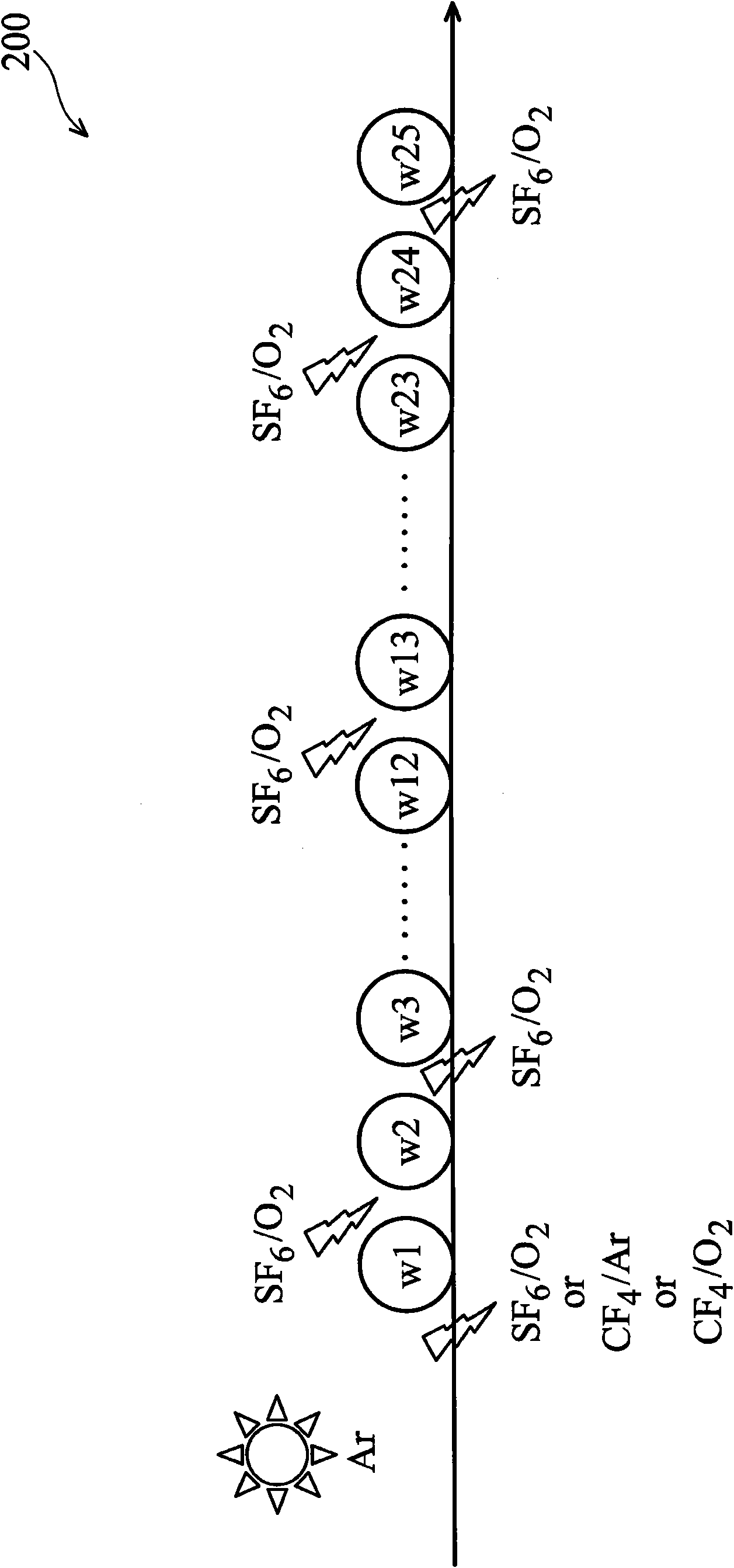

[0014] The following will refer to figure 1 and figure 2 Method 100 is described. FIG. 1 shows a flowchart of one embodiment of a method 100 for preconditioning and stabilizing a process chamber. figure 2 Timing table 200 is shown as partial or complete in various processes according to an embodiment of method 100 . It is appreciated that additional steps may be added before, during, and after the method 100, and in additional embodiments,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com