Stabilized premix for rigid polyurethane foam

A technology of rigid polyurethane and premix, which is applied in the field of storage stabilizers, can solve the problems not mentioned, and achieve the effects of stable reaction characteristics, improved storage stability, and uniform appearance

Inactive Publication Date: 2012-08-29

CENT GLASS CO LTD

View PDF14 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] As a method of maintaining the fluidity at the initial stage of foaming and improving thermal insulation performance or preventing the decomposition of the foaming agent, it is disclosed that when HFC-245fa is used as the foaming agent, the method of using an imidazole catalyst or an imidazole catalyst and a stabilizer (patent Document 9 and patent document 10), but, do not mention about when taking HFE-245pc as blowing agent, the stabilizing effect of imidazole catalyst

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

reference example 1

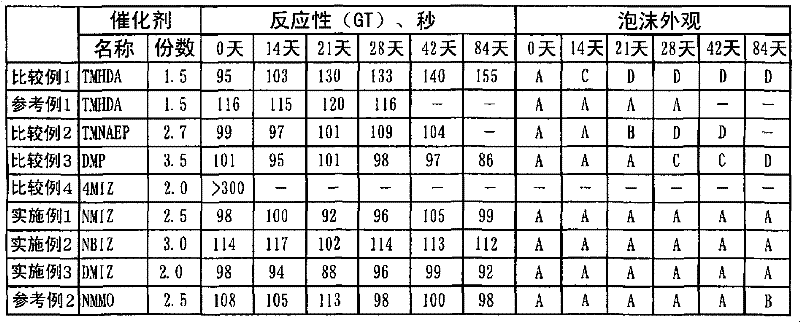

[0074] A test was performed in the same manner as in Comparative Example 1 using a mixed blowing agent of HFC-365mfc / HFC-245fa=30 / 70 (weight ratio). The results are shown in Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Login to View More

Abstract

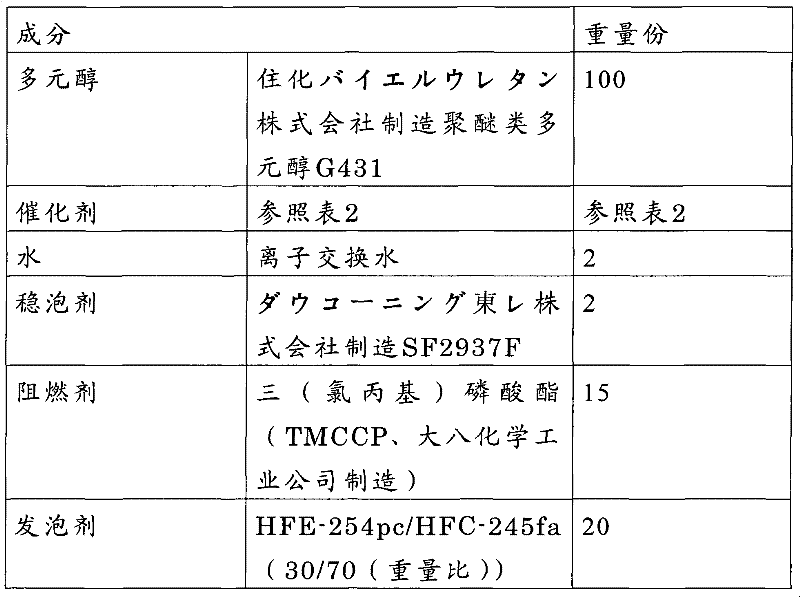

Disclosed is a method for improving storage stability of a premix which contains water and HFE-254pc as a foaming agent. Specifically disclosed is a premix for producing a rigid polyurethane foam or a polyisocyanurate foam, which contains a polyol compound, a catalyst, a foam stabilizer, a flame retardant and a foaming agent. When the foaming agent is composed of 1,1,2,2-tetrafluoroethylmethylether (HFE-254pc), an N-substituted nitrogen-containing heterocyclic compound such as an N-substituted imidazole or an N-substituted morpholine is used as the catalyst.

Description

technical field [0001] The present invention relates to a stabilized premix for producing rigid polyurethane foam or polyisocyanurate foam, a foam using the premix, and a production method thereof. More specifically, it relates to a storage stabilizer for a premixed material using 1,1,2,2-tetrafluoroethyl methyl ether (HFE-254pc) as a blowing agent. Background technique [0002] In rigid polyurethane foam or polyisocyanurate foam, in the past as a room temperature type fluorine foaming agent, its gas thermal conductivity is small, so non-flammable monofluorotrichloromethane (CFC-11) is used, and then a Fluorodichloroethane (HCFC-141b), etc. However, due to the destruction of the stratospheric ozone layer due to the chlorine atom contained in the molecule, and the increase in the amount of ultraviolet light transmitted to the ground, it has brought adverse effects on the ecosystem. These chlorofluorocarbons (CFC) or hydrochlorofluorocarbons (HCFC) are produced and used in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G18/20C08G18/00C08J9/14C08G101/00

CPCC08G2101/0025C08G18/2018C08G18/2027C08J9/143C08J2375/04C08J2203/146C08G2105/02C08G2110/0025C08G2115/02

Inventor 玉井良一日比野泰雄

Owner CENT GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com