Method for the wet-chemical transformation of biomass by hydrothermal carbonization

A biomass conversion technology, applied in the fields of biofuels, waste fuels, solid fuels, etc., can solve the problems of uneconomical hydrothermal carbonization process, not providing high yield, and products not having constant quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

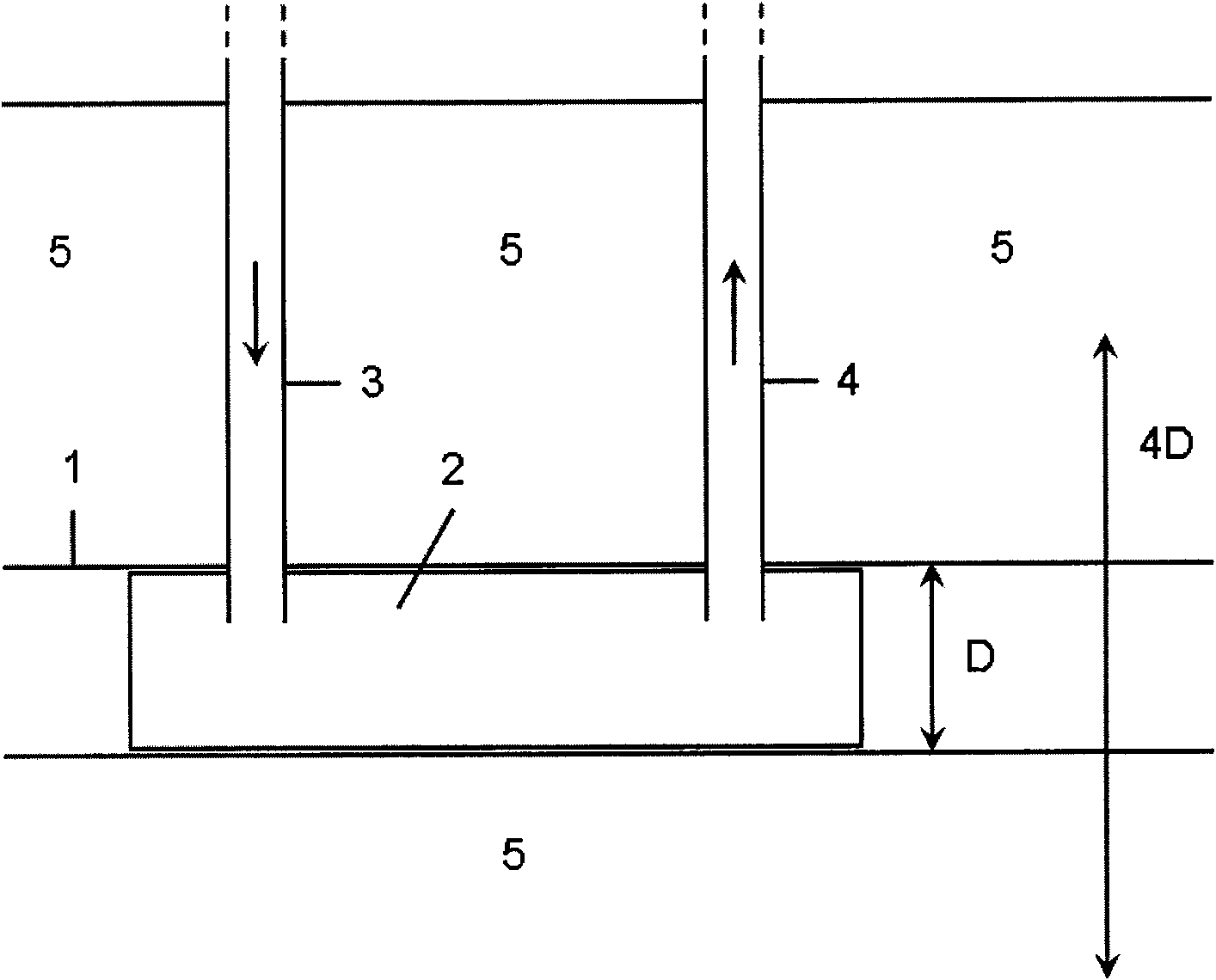

[0054] figure 1 An embodiment of a reactor for carrying out the process according to the invention is shown schematically, which in this example is embedded in a tube well 1 below ground. The tube well 1 is located at a depth of 200m. The reactor 2 has an inlet 3 to the reaction volume, which in this case occupies the entire volume of the horizontally arranged reactor. Suspended biomass is pumped into the reaction volume via this inlet 3 . The reaction product is again pumped upwards via outlet 4 . The walls of the reactor 2 can be relatively thin, since in this case the hydrostatic pressure is absorbed by the surrounding soil 5 . Here, the reactor 2 is surrounded by soil 5 which corresponds to at least four times the diameter D of the reaction volume. There is no larger hollow space in the peripheral region, so that the total mass in the volume occupied by the material in the peripheral region corresponds to at least 8 times the mass of the reaction mixture in the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com