Construction method for connecting part of PHC tubular piles

A technology of PHC pipe piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, reinforced molding, etc., can solve the problem of insufficient vertical uplift bearing capacity and compressive bearing capacity of joints, discontinuous weld seams, cost Advanced issues, to achieve strong pull-out bearing capacity and compressive bearing capacity, to avoid twists and turns or even breakage, and to achieve good connection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0058] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 Shown, the construction method of the junction of PHC pipe pile of the present invention, its steps are as follows:

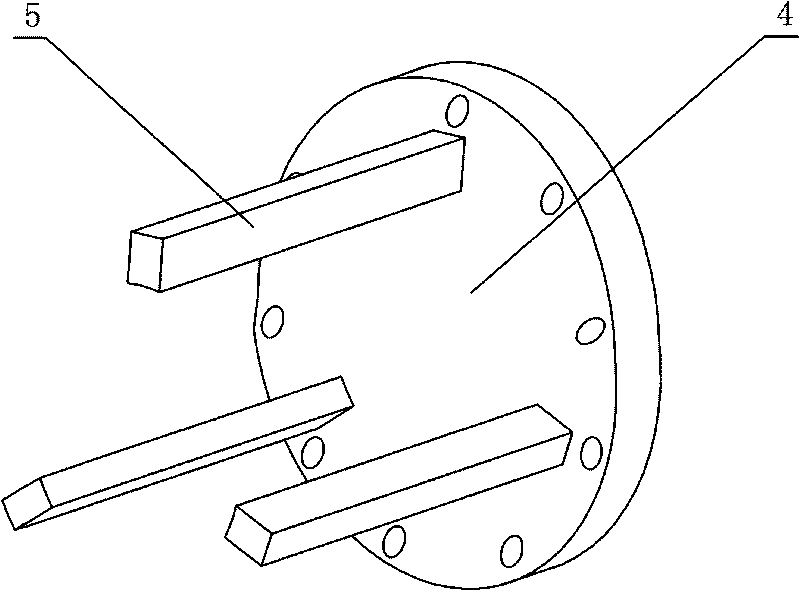

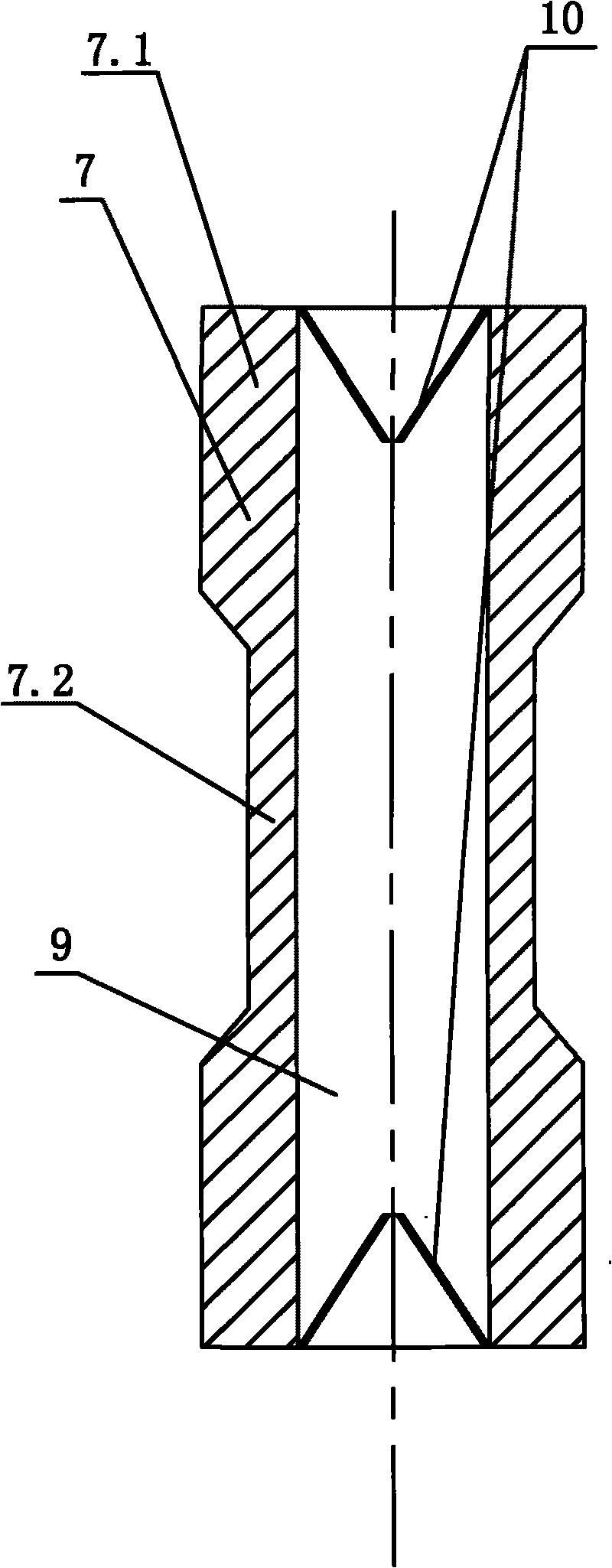

[0059] (1) Prepare a plurality of PHC pipe piles 8 with no end plates at both ends and three axially extending slots 6 at each end; all PHC pipe piles 8 in this embodiment adopt the PHC pipe piles prepared in step 1 8.

[0060] The specific operation sequence of step (1) is as follows:

[0061] a. Place the lower template;

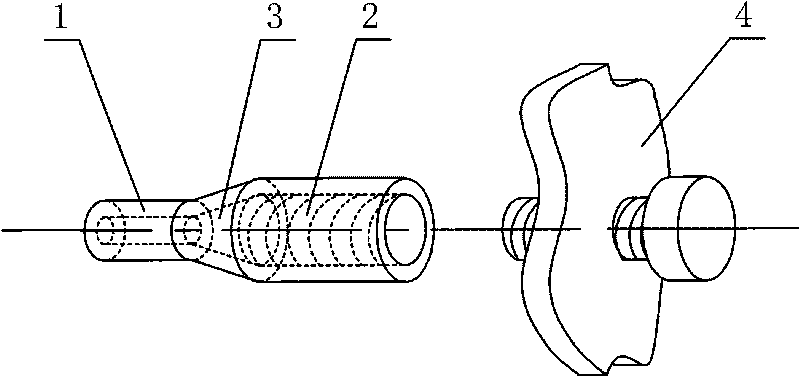

[0062] b. Prepare several tension joints 1 with threaded holes 2 and bell mouth 3. The threaded holes 2 are located outside the bell mouth 3 and both are coaxial. The tension joints 1 are made of round steel through a conventional machine. processed;

[0063] C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com