Vacuum thermal insulation pipe casing

A technology of vacuum insulation and pipe sleeves, which is applied in the direction of heat preservation, pipeline protection through heat insulation, pipeline protection, etc. It can solve the problems of unsightly appearance of pipe sleeves, inconvenient installation and use, and impact on service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

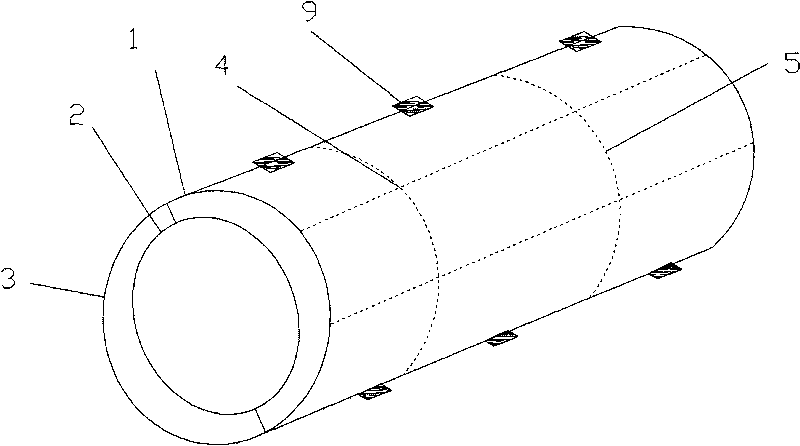

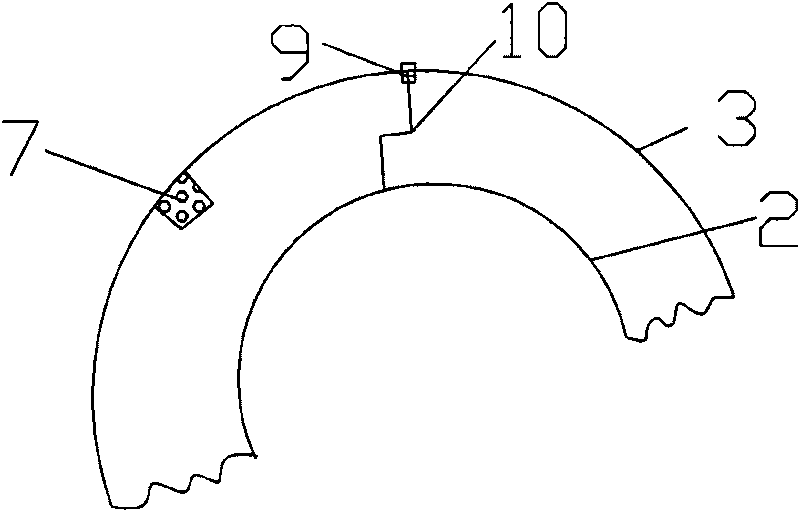

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention is composed of two halves of a semicircular cross section, the sleeve 1 is made of a stainless steel inner layer 2 and an outer layer 3 sealed, and the inside is vacuumed; the sleeve 1 is provided with There is a mesh body 5 composed of reinforcing ribs 4 .

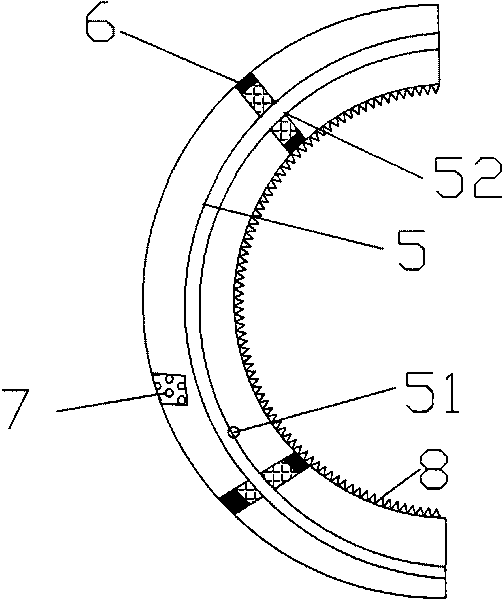

[0016] figure 2 As shown, the mesh body 5 is composed of a set of transverse reinforcing ribs 51 and a set of vertical reinforcing ribs 52 arranged in a staggered manner. The reinforcing ribs 4 constituting the net-like body 5 are in contact with the inner walls of the upper and lower stainless steel inner layers 2 and stainless steel outer layers 3 respectively through the heat insulation pad 6 at the upper and lower ends; the sides of the stainless steel outer layer 3 or A vacuum point 7 is provided on the front side.

[0017] In other embodiments of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com