Liquid crystal aligning agent and liquid crystal display device

A technology of liquid crystal display element and liquid crystal aligning agent, which is applied in the direction of liquid crystal materials, chemical instruments and methods, optics, etc., and can solve the problems of not getting enough voltage retention rate, not very good performance, and insufficient improvement of afterimage performance

Active Publication Date: 2010-04-07

JSR CORPORATIOON

View PDF9 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, compared with the above-mentioned TN-type and STN-type liquid crystal display elements, the performance is not very good, and it is necessary to improve the performance of vertical alignment and afterimage performance of liquid crystal display elements.

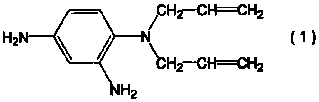

In order to solve the above-mentioned problems, attempts have been made to focus on the relationship between voltage retention and afterimage performance, and to use polyimide or its imidized polymer synthesized by a diamine compound having an allyl group in a liquid crystal alignment film to improve voltage retention, and thereby improve the residual performance (see Patent Document 2), but even with this technology, the improvement of the residual image performance is still not good enough

In addition, it has also been attempted to use polyamic acid synthesized from tetracarboxylic dianhydride containing 1,2,3,4-cyclobutane tetracarboxylic dianhydride and pyromellitic dianhydride as a liquid crystal aligning agent to improve voltage retention. rate, residual charge, and afterimage performance (see Patent Documents 3 to 6), but there is a problem that sufficient voltage retention cannot be obtained when using these technologies

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Synthetic example 1

Synthetic example 2

Synthetic example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Login to View More

Abstract

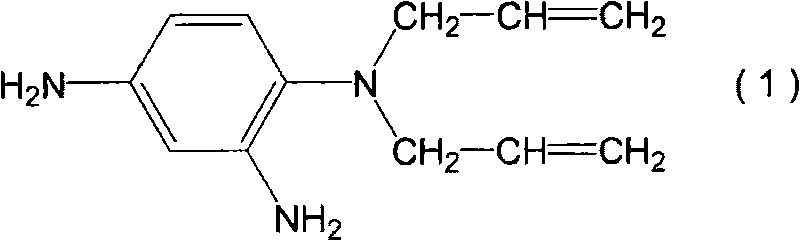

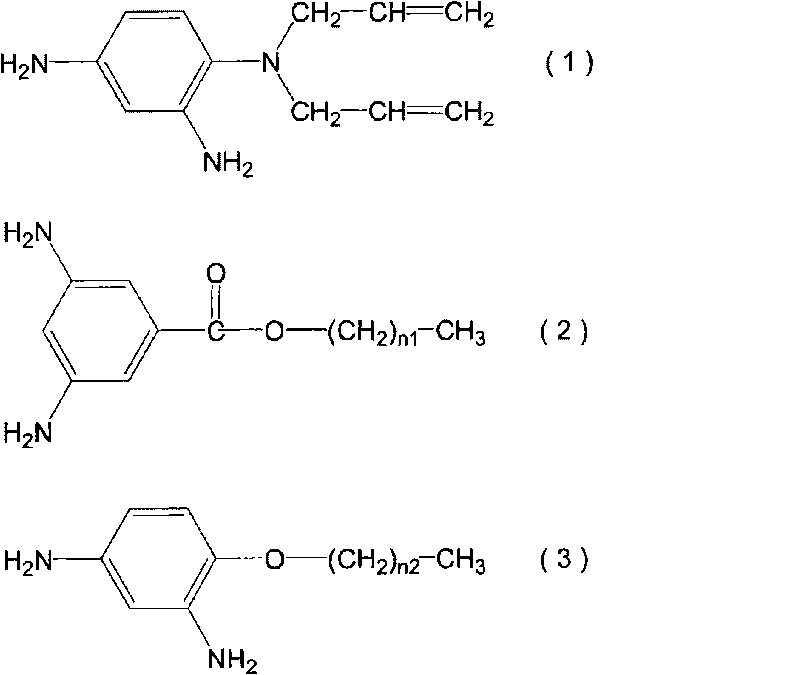

To provide a liquid crystal aligning agent that exhibits good liquid crystal aligning property, when applied to not only a TN (twisted nematic) and STN (super-twisted nematic) type but a vertical alignment liquid crystal display element and gives a liquid crystal alignment layer excellent in a voltage retention rate and image retention characteristics. The liquid crystal aligning agent contains at least one kind of polymer selected from among a group consisting of polyamic acids and their imidized polymers that are obtained by making tetracarboxylic acid dianhydride containing 1,2,3,4-cyclobutane tetracarboxylic acid dianhydride and pyromellitic acid dianhydride react with a diamine containing a compound, expressed by formula (1) and a specified compound represented by 3,5-diaminnobenzoicacid hexadecyl.

Description

technical field The present invention relates to a liquid crystal aligning agent and a liquid crystal display element. More specifically, it is related with the liquid crystal aligning agent which can form the liquid crystal aligning film excellent in voltage retention and excellent afterimage performance, and the liquid crystal display element excellent in afterimage performance. Background technique At present, as a liquid crystal display element, a TN-type liquid crystal display element having a so-called TN-type (twisted nematic) liquid crystal cell has been widely known. film, as a substrate for liquid crystal display elements, the two substrates are arranged opposite to each other, and a nematic liquid crystal layer with positive dielectric anisotropy is formed in the gap to form a box with a sandwich structure. The long axis of the liquid crystal molecules changes from one The substrate is continuously twisted 90 degrees to the other substrate. In addition, an STN (...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02F1/1337

CPCC09K19/56G02F1/1337

Inventor 泉谦一阿部翼林英治

Owner JSR CORPORATIOON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com