Adhesive composition and surface protection film

一种组合物、粘结剂的技术,应用在胶粘剂、粘合剂类型、酯共聚物粘合剂等方向,能够解决再加工性易降低、难再次剥离、粘结剂残留等问题,达到耐污染性良好、防止粘结剂残留现象、的平衡性优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] Nitrogen gas was introduced into a reaction apparatus equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen introduction pipe, thereby replacing the air in the reaction apparatus with nitrogen. Then, added 100 parts by weight of 2-ethylhexyl acrylate, 3.0 parts by weight of 8-hydroxyoctyl acrylate, 10 parts by weight of polypropylene glycol monoacrylate (forming polyalkylene glycol chain The average repetition number of alkylene oxide n=12), and 60 parts by weight of solvent (ethyl acetate) was added at the same time. Then, 0.1 parts by weight of azobisisobutyronitrile as a polymerization initiator was dropped over 2 hours, and reacted at 65° C. for 6 hours to obtain acrylic acid used in Example 1 with a weight average molecular weight of 500,000. Copolymer Solution 1. A part of the acrylic copolymer was used as a sample for acid value measurement described later.

Embodiment 2~9 and comparative example 1~4

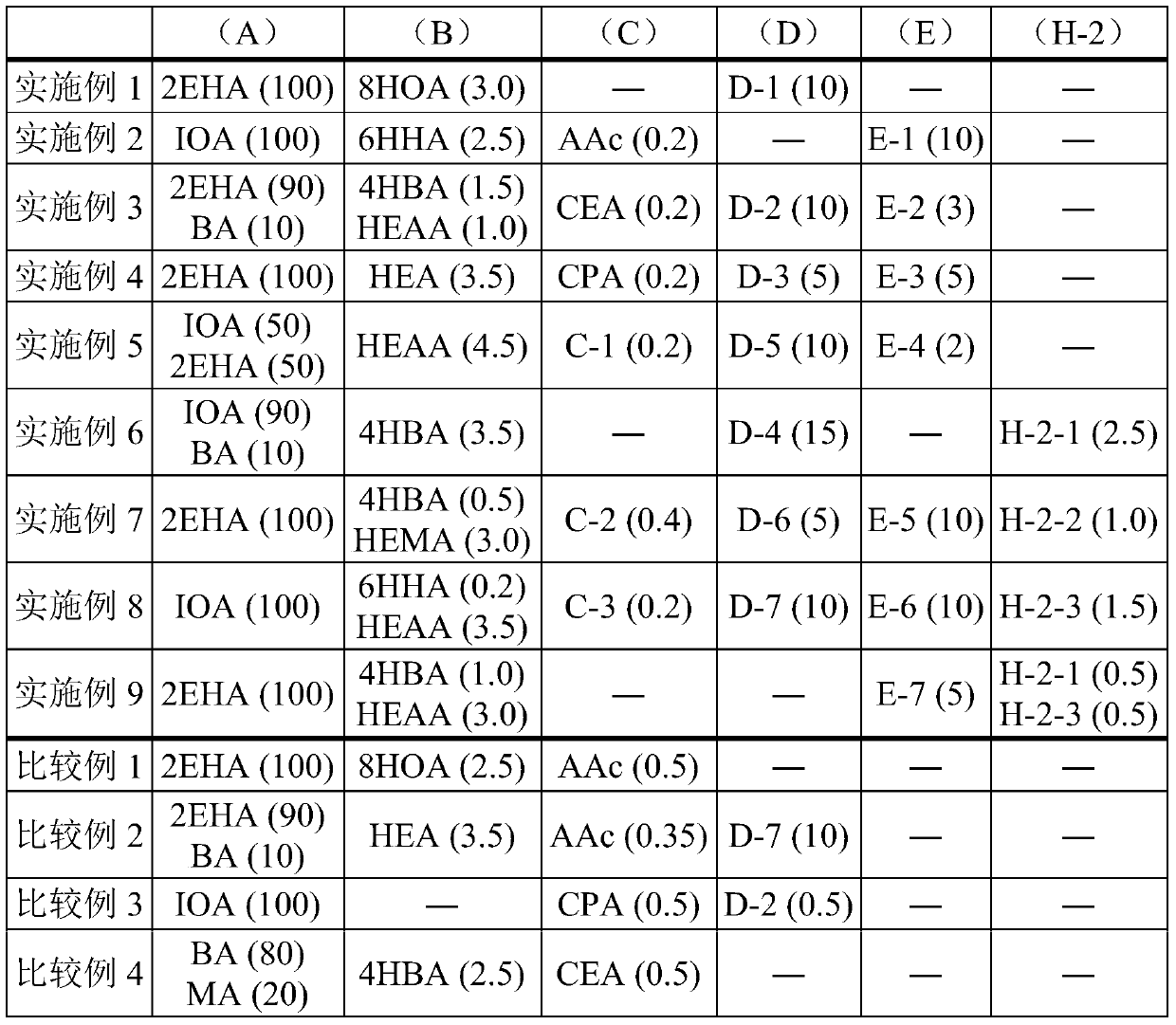

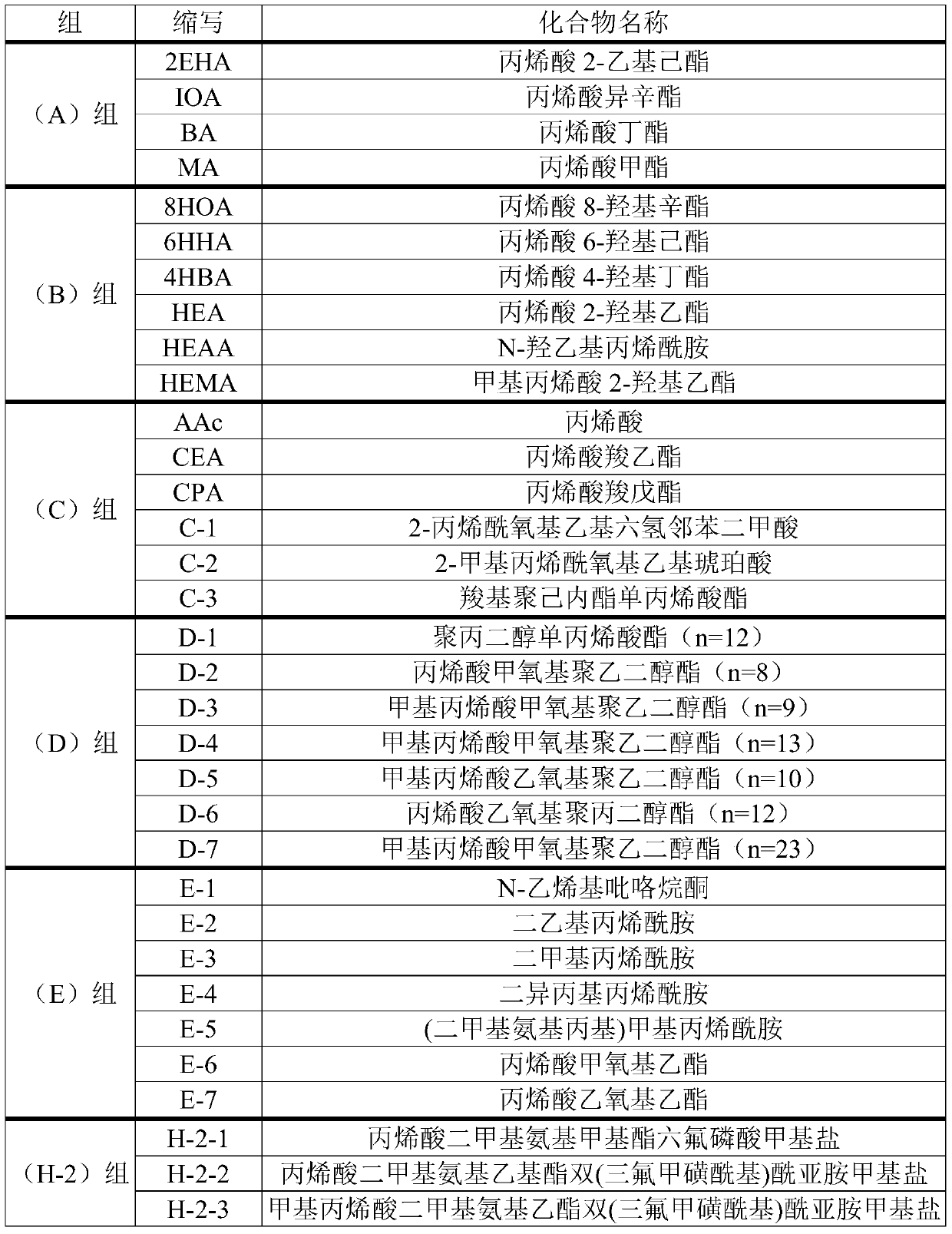

[0123] Except that the composition of each monomer was adjusted as described in (A) to (E) and (H-2) in Table 1, it was carried out in the same manner as the above-mentioned acrylic copolymer solution 1 used in Example 1, Acrylic copolymer solutions used in Examples 2-9 and Comparative Examples 1-4 were obtained.

[0124] Table 1

[0125]

[0126]

[0127] [Example 1]

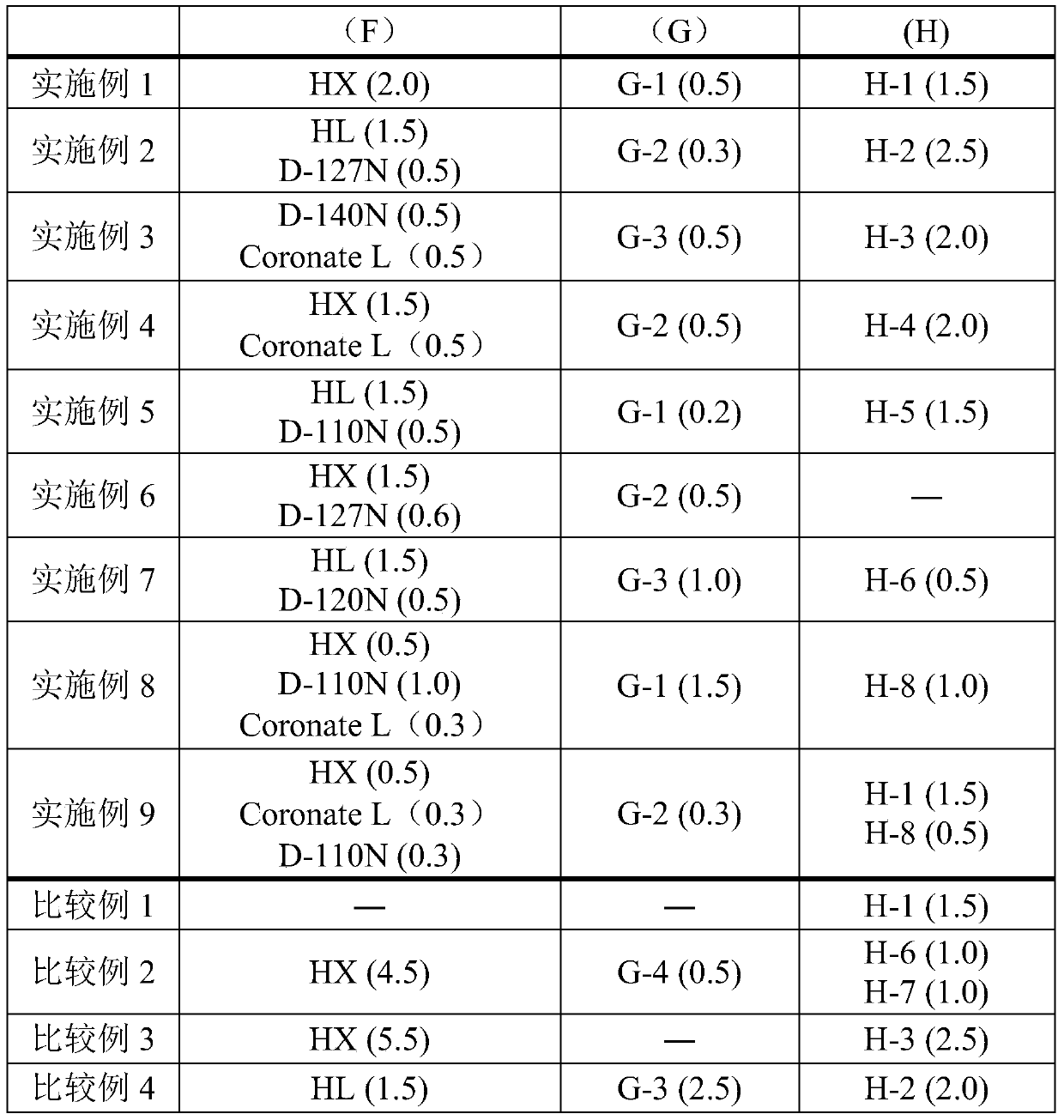

[0128] To the acrylic copolymer solution 1 of Example 1 produced as described above, 1.5 parts by weight of 1-octylpyridinium hexafluorophosphate was added and stirred, and then 2.0 parts by weight of Coronate HX (coronet HX, hexamethylene The isocyanurate of the diisocyanate compound), 0.5 parts by weight of the difunctional acyclic aliphatic isocyanate compound G-1 of Synthesis Example 1, and then stirred and mixed to obtain the adhesive composition of Example 1. This adhesive composition was coated on a release film composed of a polyethylene terephthalate (PET) film coated with a silicone resin, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com