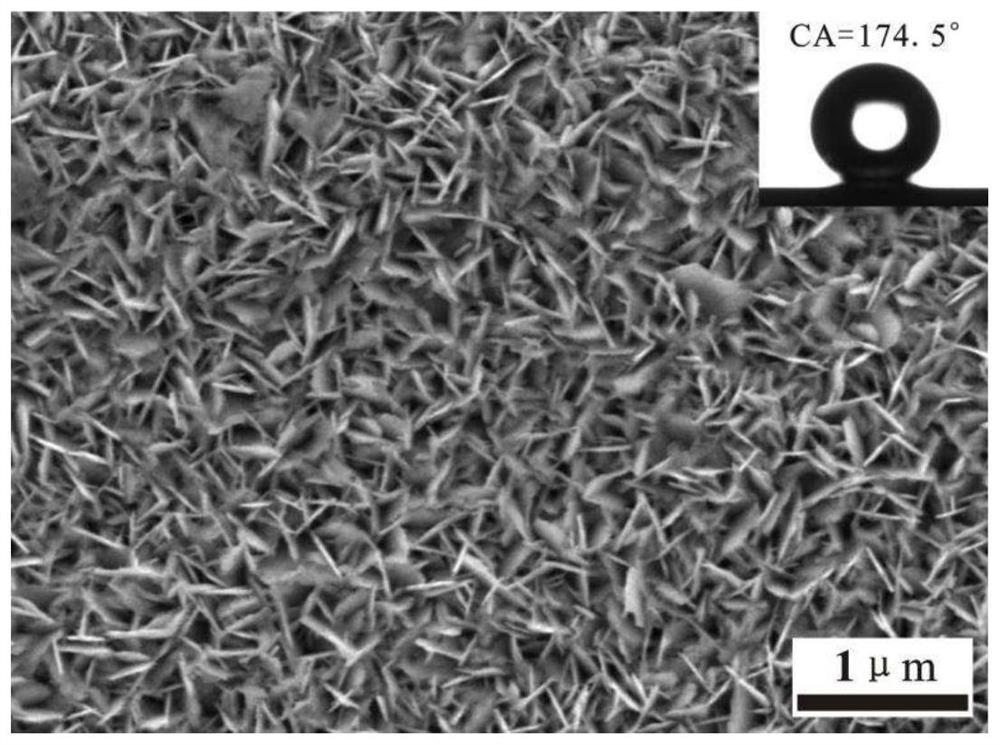

Preparation method and application of ultrahigh-adhesiveness super-hydrophobic brass surface

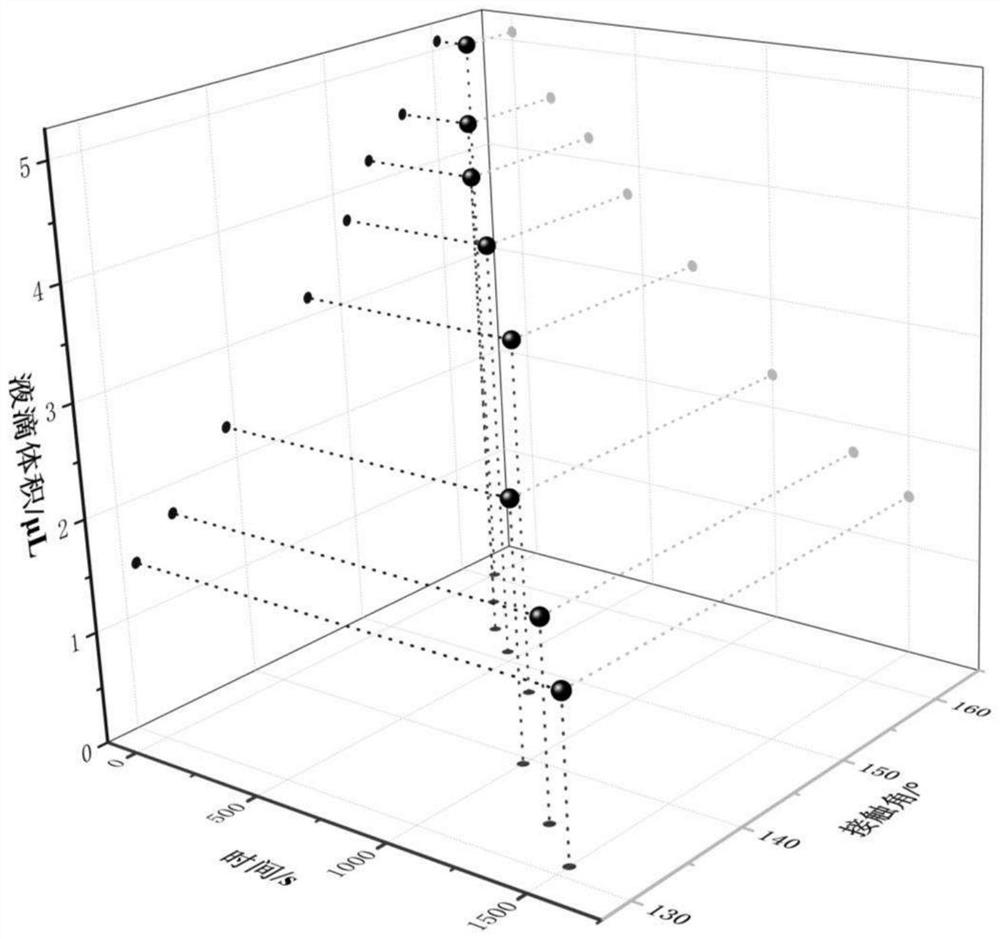

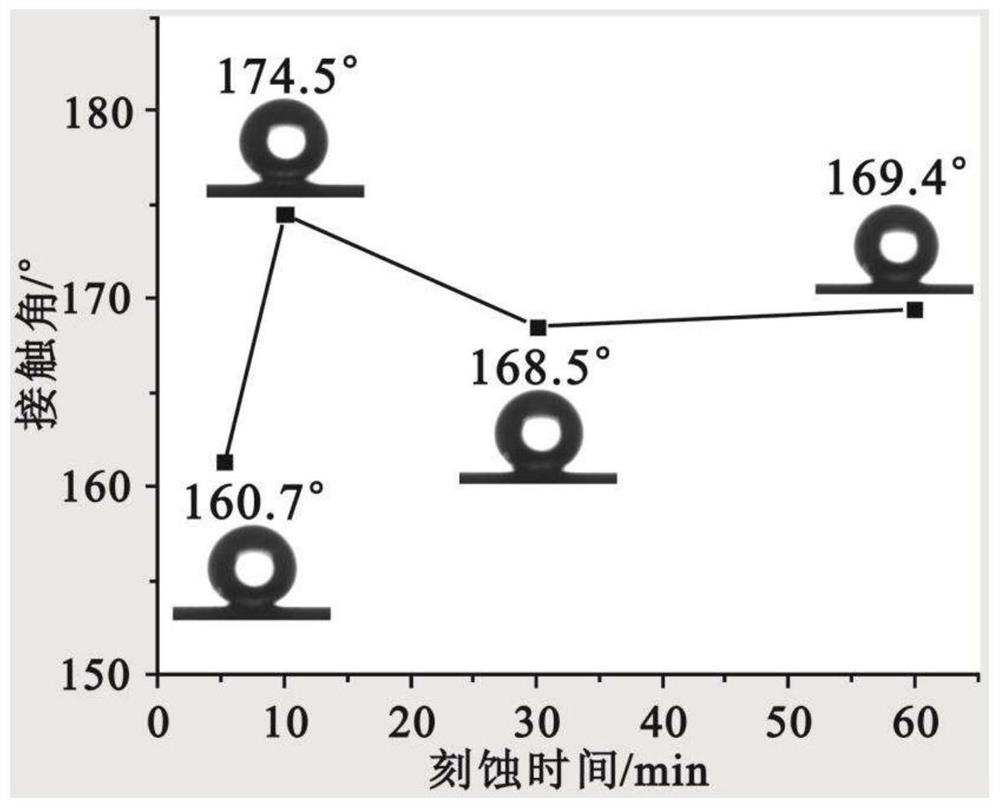

An adhesive and super-hydrophobic technology, applied in the field of electrochemistry, can solve the problems of very little research on the preparation of controllable and highly adhesive super-hydrophobic surfaces, the surface contact angle is not high enough, and it is not easy to mass-produce, etc., to achieve excellent super-hydrophobic performance, Excellent high adhesion properties, enhanced SERS detection strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further illustrate the technical means adopted by the present invention to achieve the predetermined purpose, the specific implementation, structural features and functional characteristics of the present invention will be described in detail below in conjunction with the accompanying drawings. Wherein, the same number refers to the same or similar term throughout the text. Although several examples and illustrations are shown below, the invention described herein is not limited to the examples and illustrations specifically shown, but also includes other applications of the invention and obvious variations and equivalents thereof. Unless expressly stated otherwise, the terms used herein are to be interpreted in their plain and conventional meaning. The terms should not be interpreted in any restrictive or restrictive manner merely by virtue of their use in connection with the description of certain specific embodiments of the invention.

[0046] In one emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com