Management and control integrated system and method for detecting strength of cement concretes

A cement concrete, strength testing technology, applied in material inspection products, instruments, data processing applications, etc., can solve the problems of data fraud, poor management, and confusing filling in content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

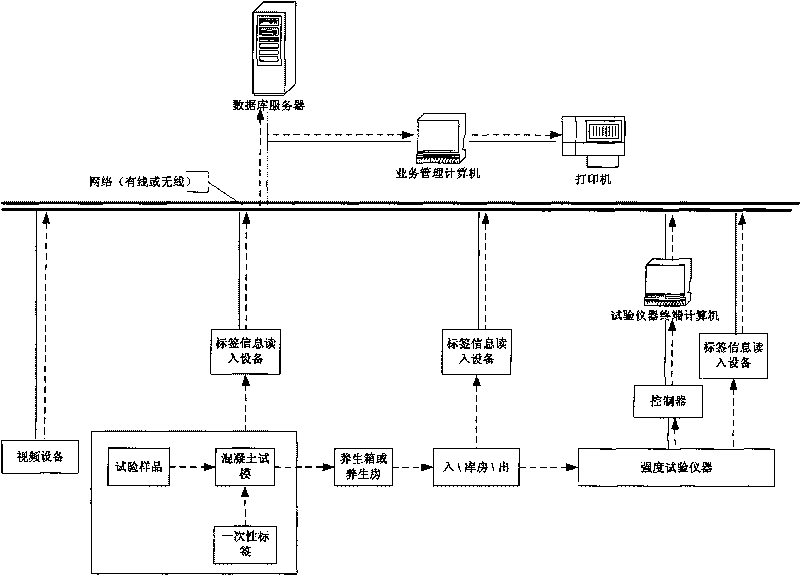

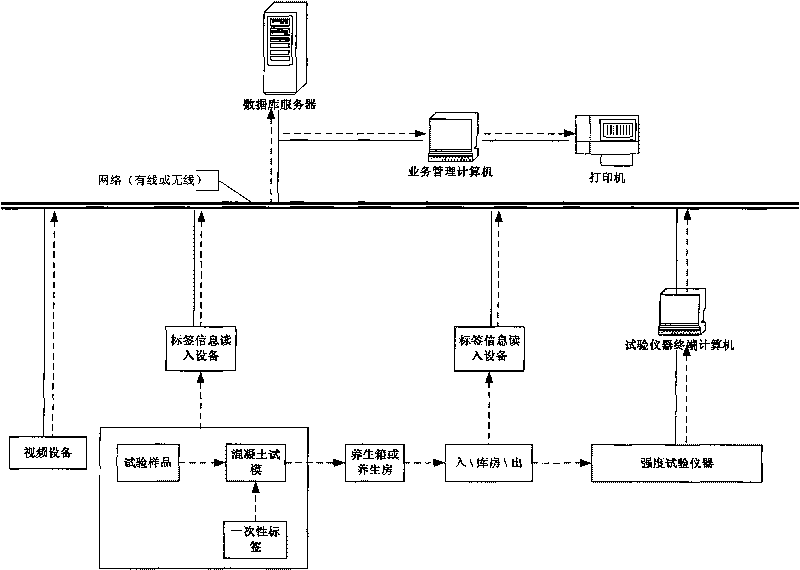

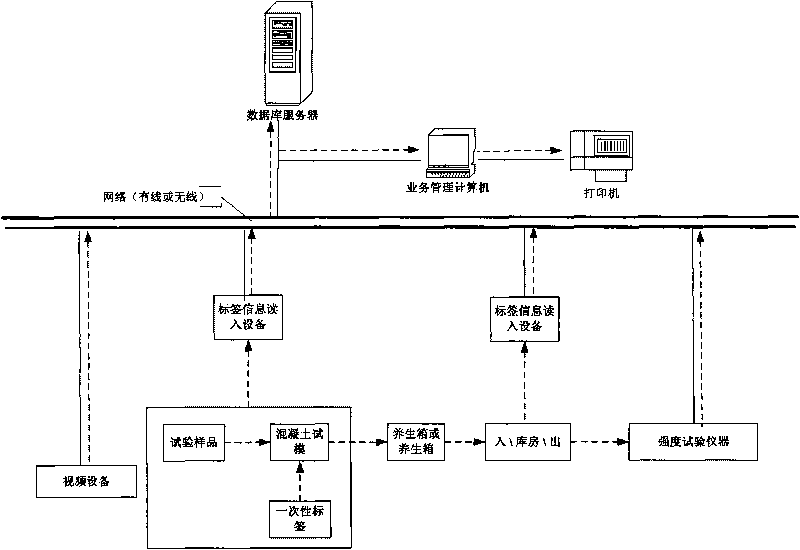

[0012]Referring to the accompanying drawings, an integrated system and method for cement and concrete strength detection, control, and control includes hardware and software. Health care room, strength test equipment, business management computer, database server and printer; software includes data acquisition software, transmission tool software and business management software; there are three situations for strength testing instruments: the first situation is that the strength testing instrument does not have the function of automatic data collection After intelligent transformation, the test piece testing instrument, controller and terminal computer are combined to form a new strength testing instrument to realize the automatic collection function. The strength testing instrument is connected to the controller through the network, and the controller is connected to the terminal computer through the network. The terminal computer is connected to the database server through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com