Low temperature-resistant and distortion-resistant power cable with copper conductor TPE insulated sheath for wind power generation

An insulating sheath, power cable technology, applied in the direction of insulated cables, power cables, insulated conductors, etc., can solve the problem of high price, and achieve the effect of improving the cold resistance, easy degradation, and low temperature torsion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

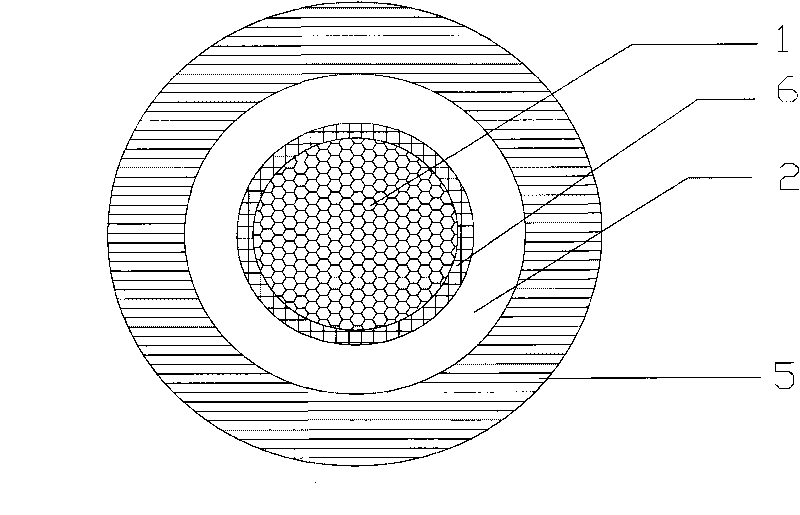

[0022] Such as figure 1 As shown, the copper core TPE insulated sheath wind power cable (single core) is conductor 1 from the inside to the outside, and the conductor wrapping 6 wrapped on the surface of the conductor is wrapped on the conductor wrapping layer. The TPE insulation 2 and the TPE sheath 5 covering the insulation.

[0023] The production process of the copper core TPE insulated sheathed wind power cable with severe cold resistance and twist resistance (single core) includes the following steps in sequence: during production, the strands are twisted by a stranding machine, and then twisted into a conductor by a twisting machine 1. At the same time, use a wrapping machine to wrap the conductor on the surface of the conductor 2, use a plastic extruder to extrude the TPE insulation 3 on the conductor 1, and finally extrude the TPE sheath 4 with the extruder.

Embodiment 2

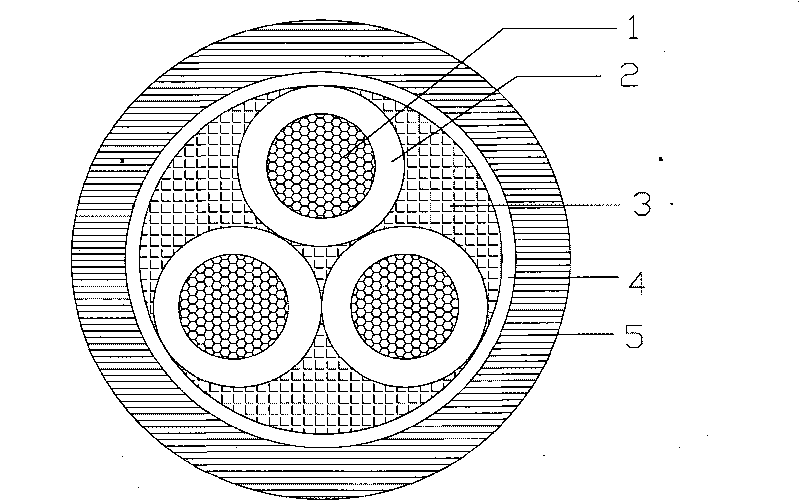

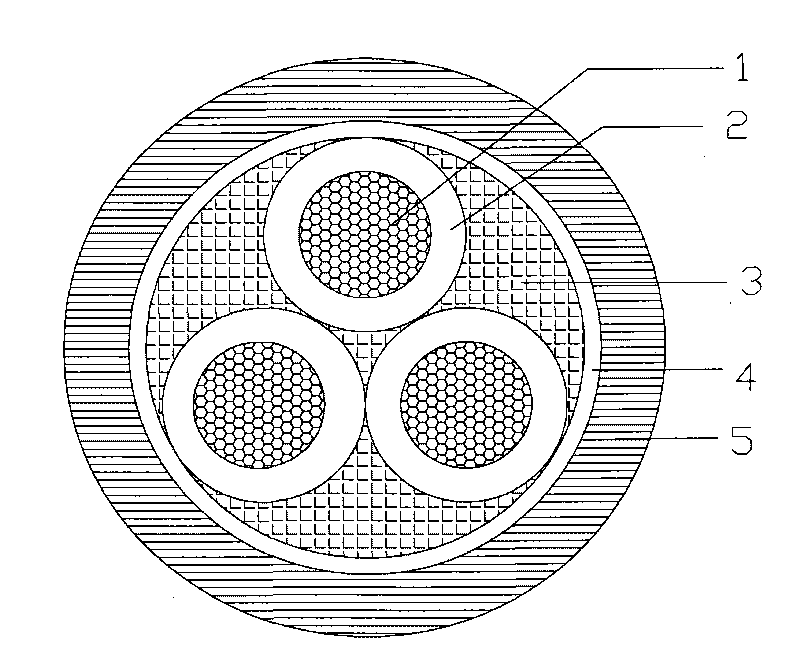

[0025] Such as figure 2 As shown, the copper core TPE insulated sheathed wind power cable (multi-core) with cold resistance and twist resistance is conductor 1 from the inside to the outside, TPE insulation 2 extruded on the surface of the conductor, and PP rope filled in the gap of the TPE insulator Filling 3, cabled wrapping 4 wrapped with TPE insulator and filled, and TPE sheath 5 wrapped on its surface.

[0026] The production process of copper core TPE insulated sheathed cold-resistant and twist-resistant power cable (multi-core) for wind power generation: During production, the strands are twisted with a wire-bunching machine, and then the conductor 1 is twisted with a stranding machine, and then plastic The extruder extrudes TPE insulation 2 on the conductor 1, then uses the cable forming machine to simultaneously fill PP rope 3 and cable wrapping 4, and finally extrudes the TPE sheath 5 with the extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com