Active measuring device of end surface of CNC internal grinding machine

An active measurement, internal grinding machine technology, applied in measurement/indication equipment, metal processing machinery parts, metal processing equipment and other directions, can solve the problems of low efficiency of positioning technology, high safety hazards, high labor intensity, etc., to improve labor efficiency , The effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

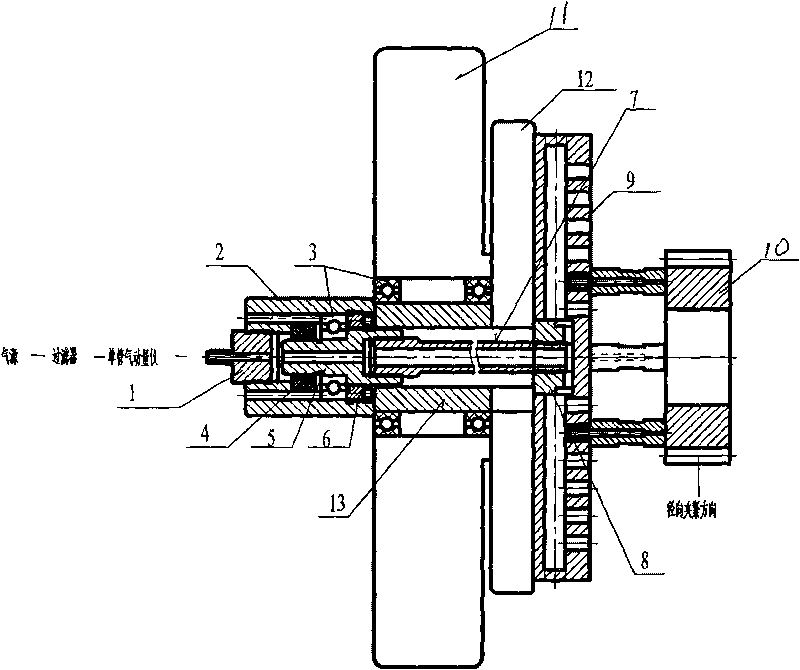

[0026] Figure 1-3 Shown is an active measurement device for the end face of a CNC internal grinding machine according to the present invention, including a machine tool, a spindle, an adjusting grinding head, and an end face positioning support plate for a CNC internal grinding fixture.

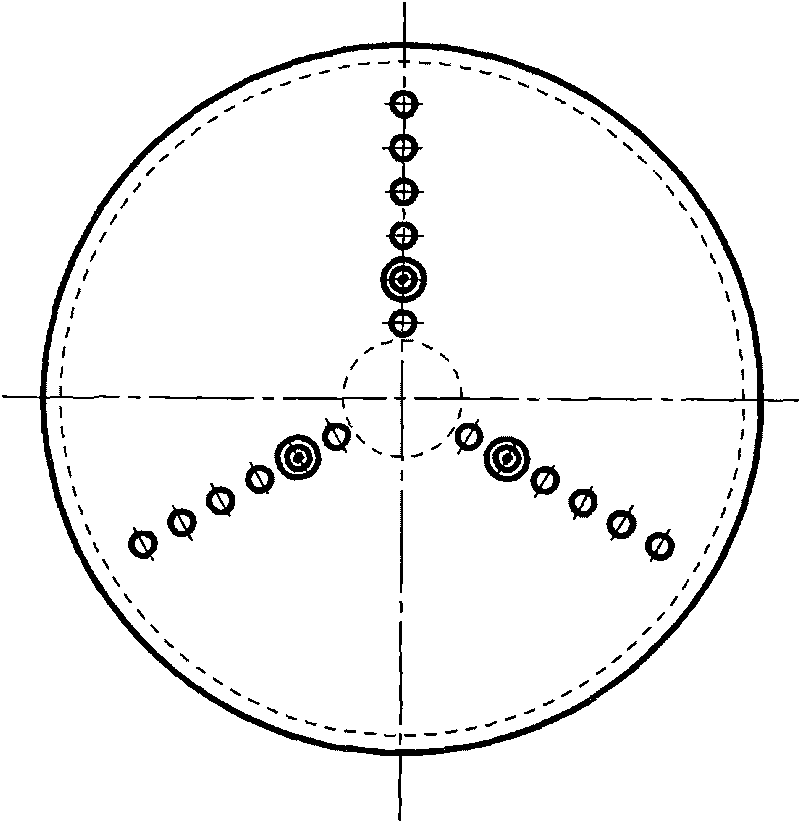

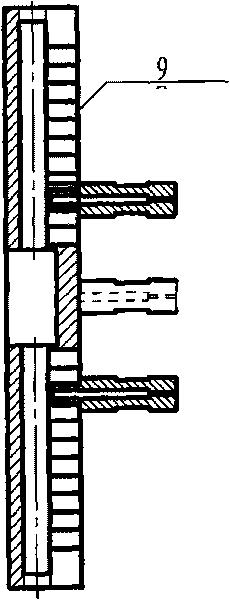

[0027] The end face positioning backing plate is a positioning faceplate 9 with six ventilation grooves inside. The positioning faceplate 9 has 6 groups processed according to the end faces of multiple workpieces, and each group includes 3 threaded holes with the same center distance evenly distributed on the positioning faceplate. The faceplate 9 is fixed on the gland 8 of the machine tool.

[0028] Positioning faceplate 9 is fixed with the positioning screw of air hole in a group of threaded holes that adapt to the end face size of processed workpiece, and all the other threaded holes are sealed with the screws that match it.

[0029] The adjusting grinding head is located near the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com