Snow removal truck used in airport

An airport snow sweeper and fan technology, which is used in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of increasing snow removal cost and operation time, difficulty in arranging snow sweeping brushes, and limited selection of equipment types. The brush height and working angle are convenient, the residual snow amount is small, and the structure is novel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

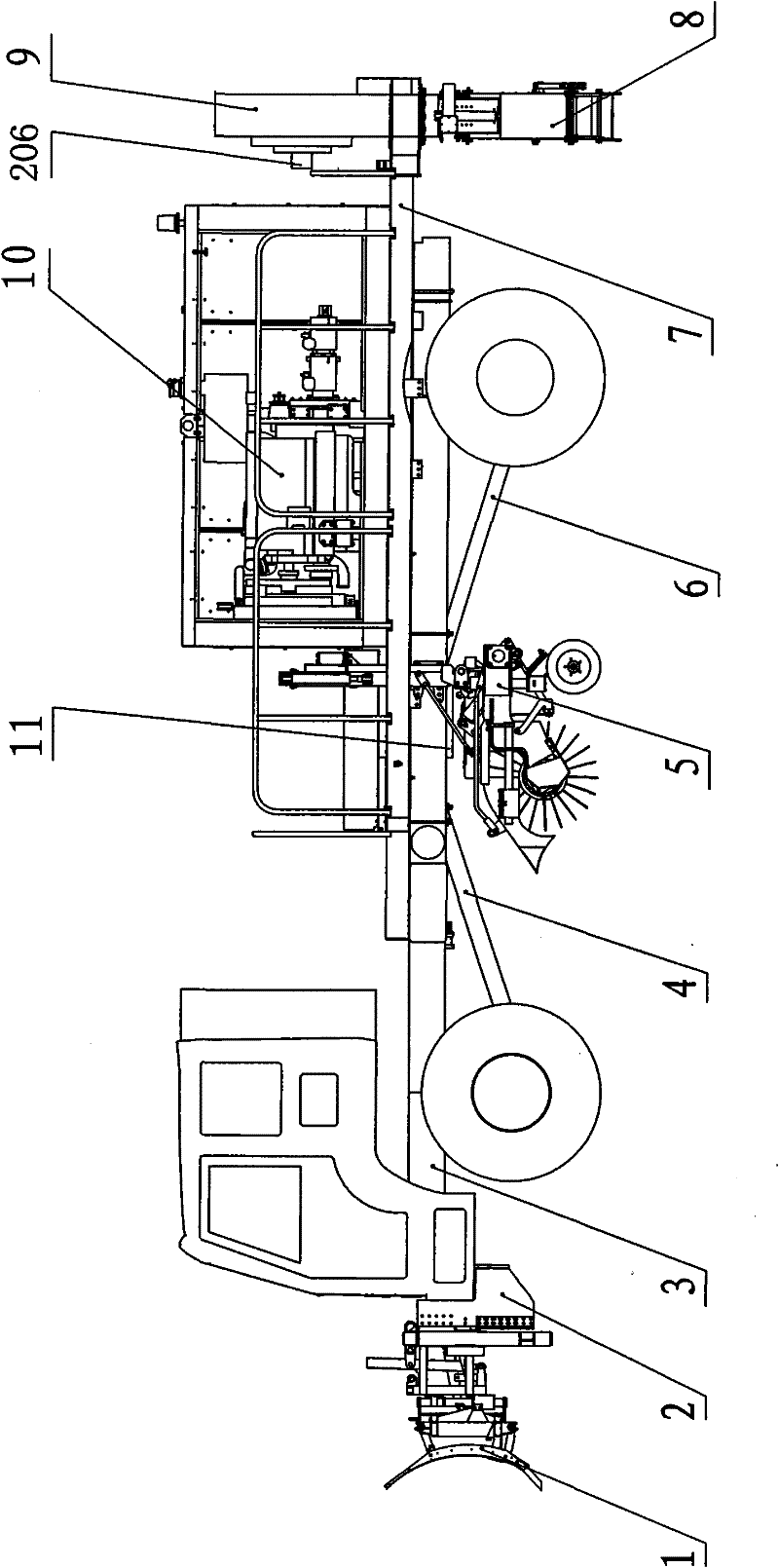

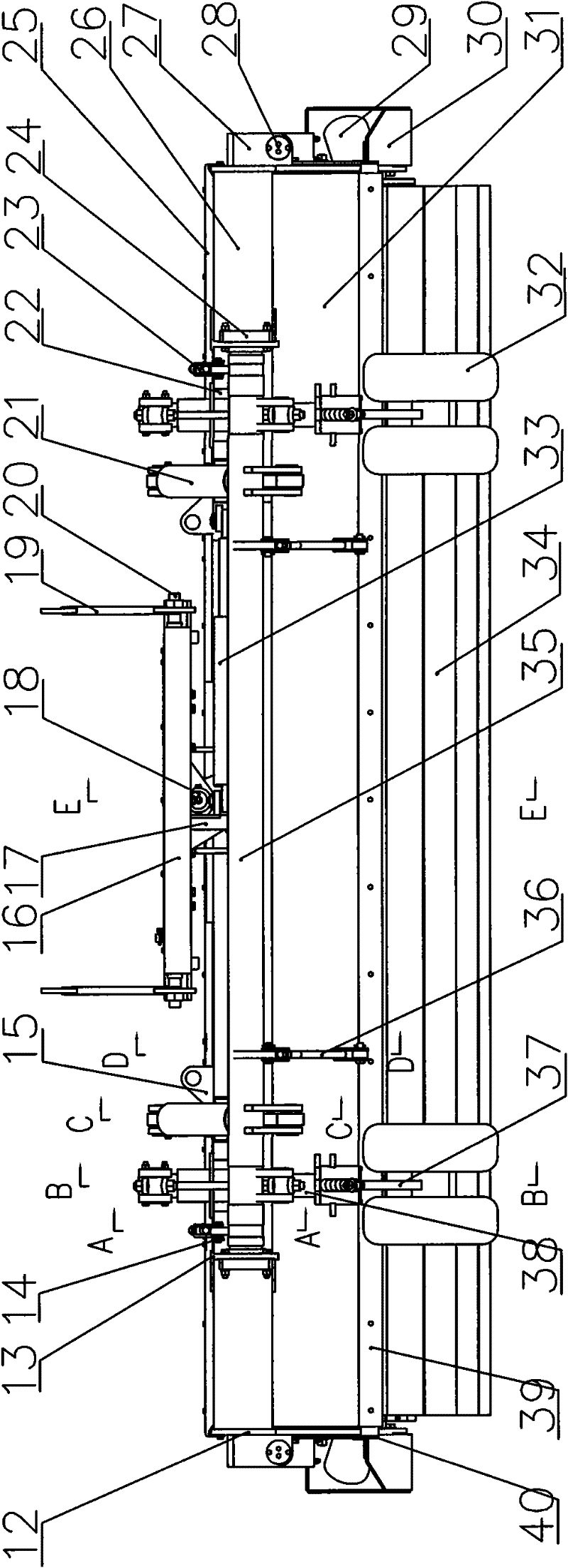

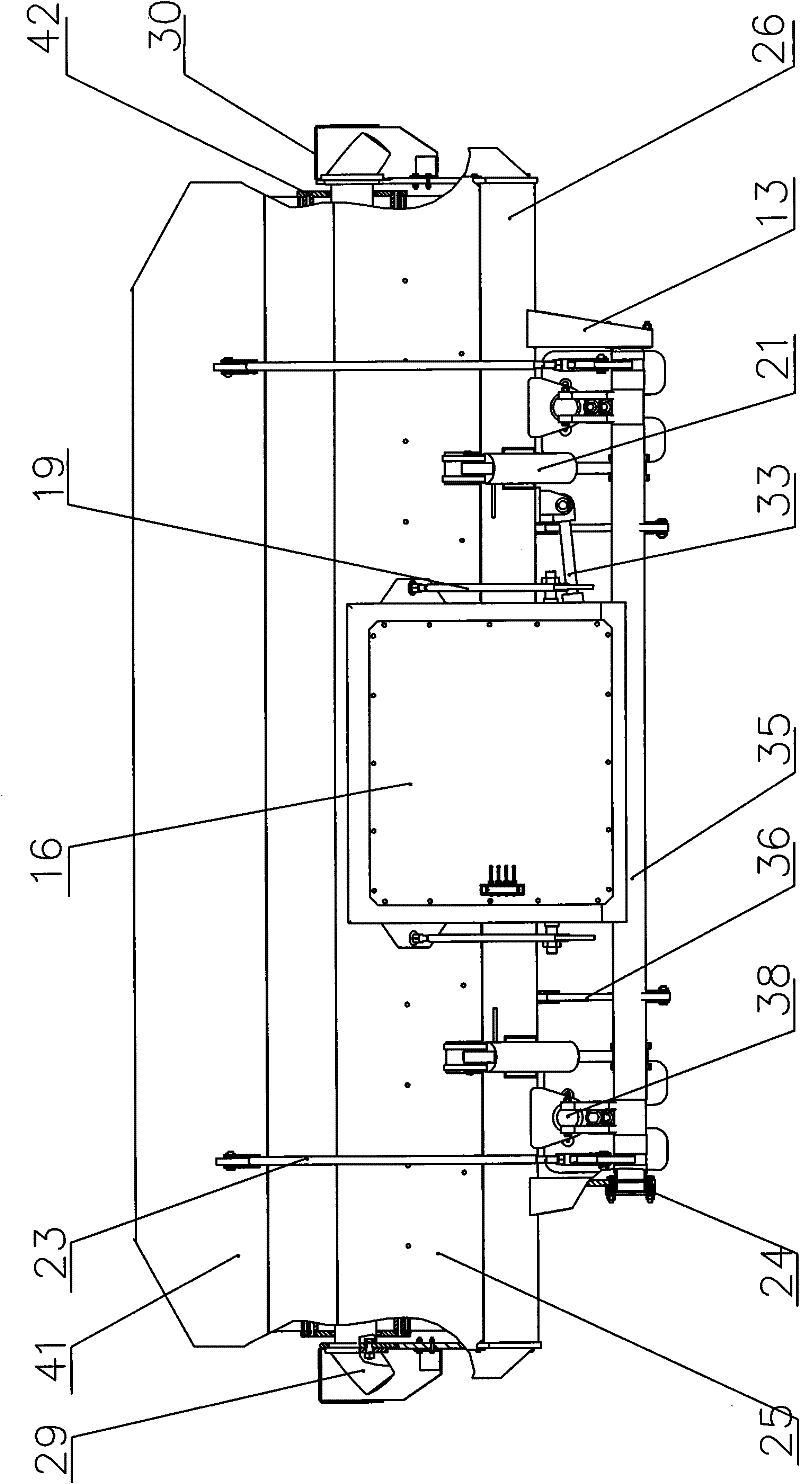

[0038] As shown in the accompanying drawings, a kind of airport snow removal vehicle is provided with a car chassis 3, a suspension device 2 and a snow shovel 1, a snow sweeping roller brush device 5 and a snow blowing device 8, and the upper part of the car chassis 3 is provided with a power transmission device 10 and The hydraulic system, the whole vehicle is equipped with a night vision monitor, the structure and connection relationship of the automobile chassis 3, the suspension device 2 and the snow shovel 1 are the same as those of the prior art. Relation is identical with prior art, this does not go into details, is provided with high position transfer case 11 on the automobile chassis 3, and high position transfer case 11 torque input shafts are connected with engine through gearbox, and high position transfer case 11-output shafts pass front The transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com