Method for conveying concrete in narrow space and device thereof

A technology in concrete and space, applied in the processing of building materials, infrastructure engineering, construction, etc., can solve the problems of difficult construction cost and temperature control, unstable concrete delivery quality, slow concrete pouring speed, etc., to reduce equipment. Dismantling and lifting work, beneficial to the safe operation of equipment, and the effect of increasing the scope of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

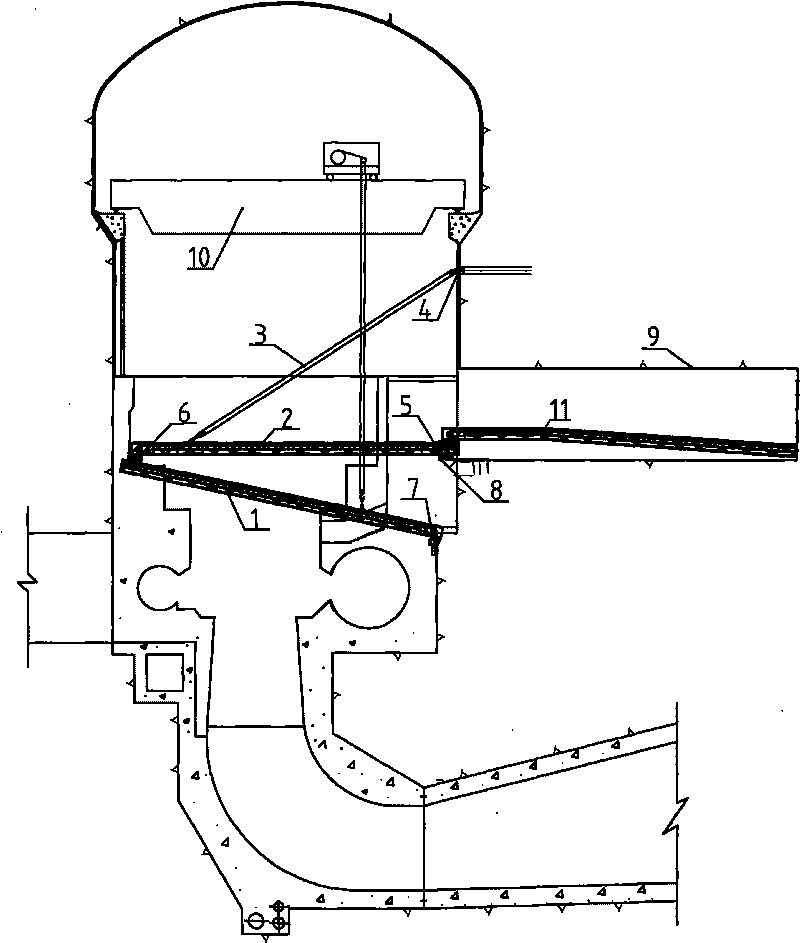

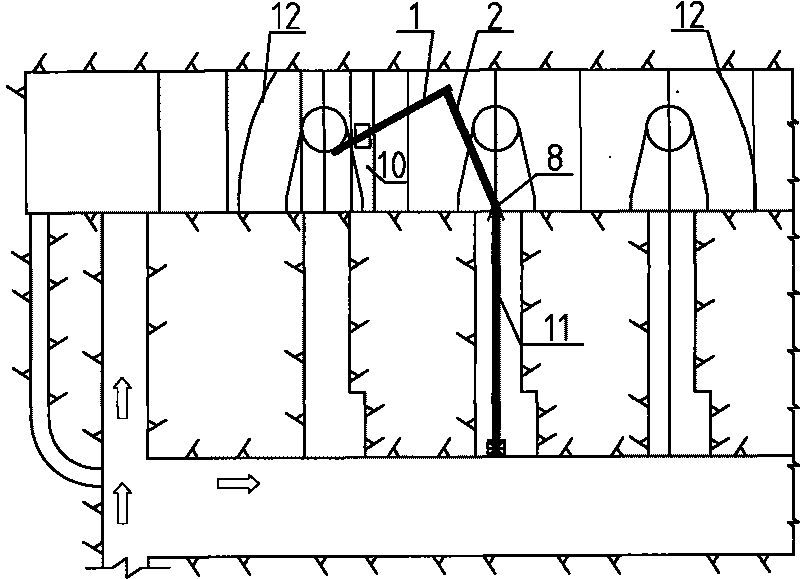

[0024] A method for conveying concrete in a narrow space, comprising the following steps:

[0025] 1) Excavate the busbar hole 9, arrange the lower anchor frame 8 on the bottom plate or the lower part of the busbar hole 9, and arrange the upper anchor point 4 between the rock anchor beam and the top of the busbar hole 9;

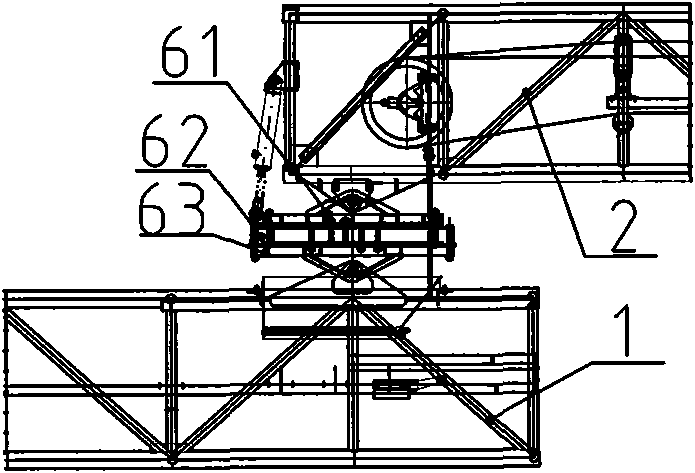

[0026] 2) The upper hinged rotary device 5 is installed on the lower anchor frame 8 to connect with the tail end of the upper truss type belt conveyor 2, and the head end of the upper truss type belt conveyor 2 is connected to the lower truss type belt conveyor 1 through the lower hinged rotary device 6;

[0027] 3) One end of the pulley device 3 is connected to the upper truss type belt conveyor 2, the other end is connected to the upper anchor point 4, and the lower truss type belt conveyor 1 is connected to the bridge crane 10;

[0028] Rapid concrete delivery in a narrow space is realized by the above method.

[0029] like figure 1 and figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com