Transmission case body with vibratory anchor drill

A technology for transmission box and rock bolt rig, which is applied in the direction of transmission box, bolt installation, transmission device, etc. It can solve the problems of no impact effect and slow drilling feed speed, etc., and achieve fast drilling feed speed, Realize the effect of rotation with impact function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

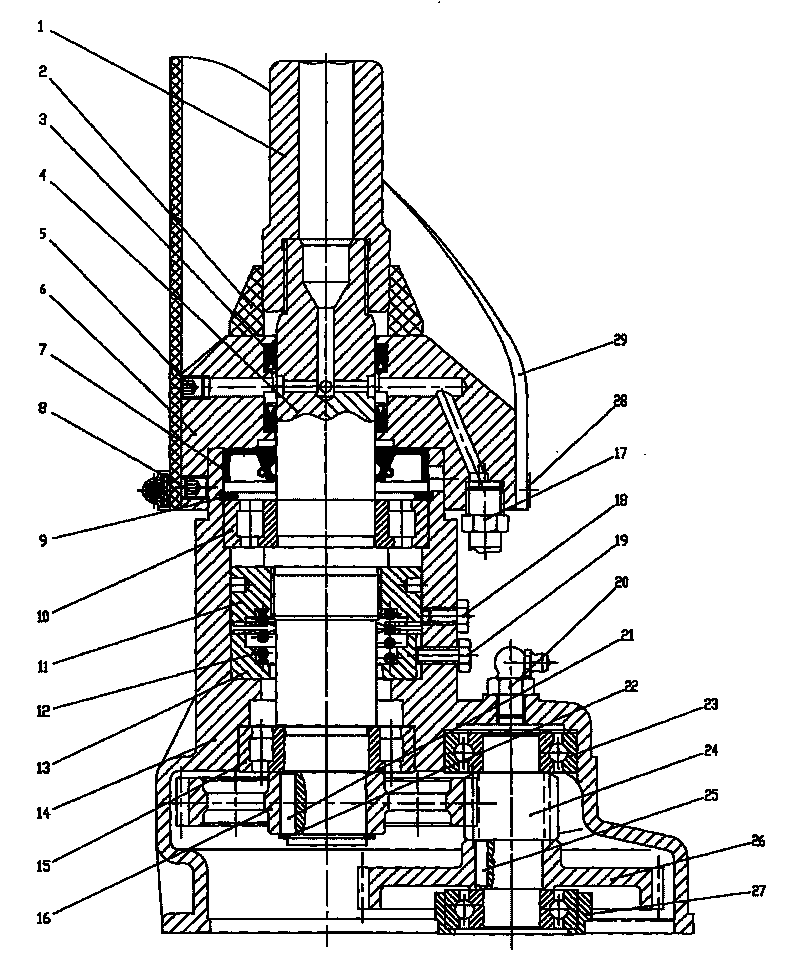

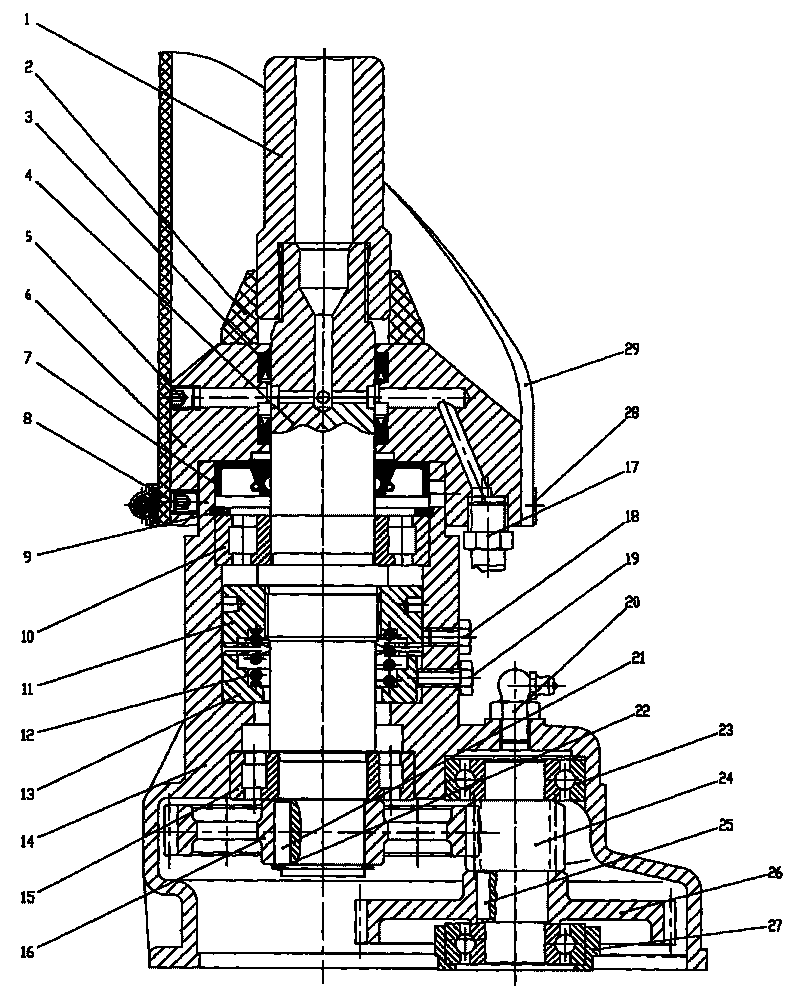

[0010] see figure 1 , figure 1 It is a structural schematic diagram of the transmission case of the rock bolter with vibration of the present invention. Depend on figure 1 It can be seen that the transmission case of the rock bolter with vibration of the present invention comprises a transmission case 14, and a gear shaft 24 is vertically installed with a bearing 23 and a bearing sleeve 27 in the transmission case 14 and with a bearing 15, a cylindrical roller A main shaft 4 is installed on the sub-bearing 10, retaining ring 9 and seal ring 7, and a driving gear 26 is installed on the gear shaft 24 with a key 25, and a driven gear 16 is installed on the lower end of the main shaft 4 with a key 21 and a retaining ring 22. The driven gear 16 meshes with the gear shaft 24, and the middle of the main shaft 4 is sequentially set with a fixed ratchet 13 and a movable ratchet 11. The fixed ratchet 13 is fixedly connected to the inner wall of the transmission box 14 with a hexagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com