Cast steel back-up roller and preparation method thereof

A roll and cast steel technology, applied in the field of steel rolling rolls, can solve the problems of spalling, increase the manufacturing cost of rolls, low rate of finished parts, etc., and achieve good wear resistance and toughness, strong anti-accident ability, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

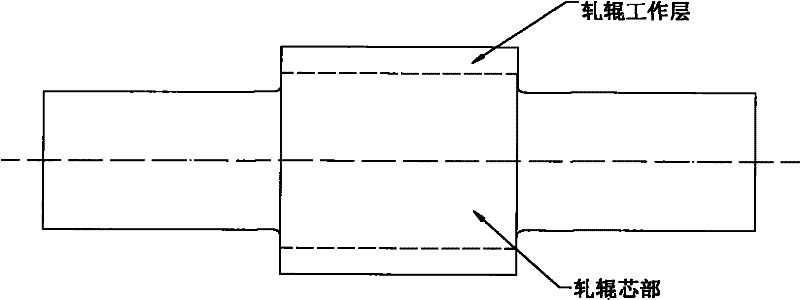

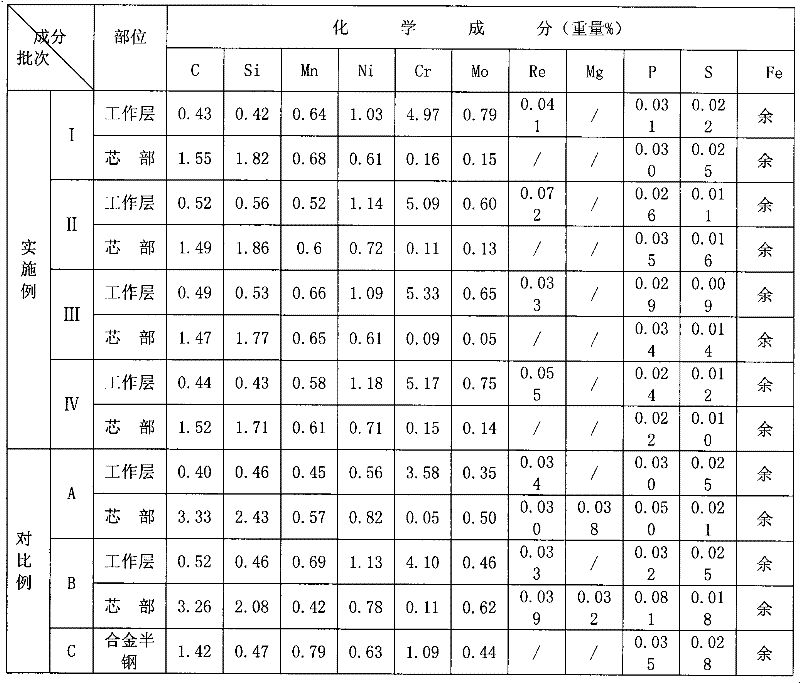

[0027] According to a new type of cast steel support roll according to the present invention, the working layer material of the roll is made of high-alloy steel, and the core material of the roll is made of graphite steel. We have produced 4 batches of cast steel back-up rolls of the embodiment of the present invention altogether successively, 4 batches of 8 rolls in total are all qualified products and sent to users for use. The chemical compositions of the working layer and core molten steel of these 4 batches of cast steel back-up rolls are listed in Table 1. Before this, we first produced 2 rolls according to the requirements of the existing patent application technology: 2009 1 0001054.9. These 2 rolls were scrapped due to the low tensile strength of the core. For the convenience of comparison, the work of these 2 composite rolls The chemical composition of layer molten steel and core molten iron is also listed in Table 1. Simultaneously, the chemical composition of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com