Stamping technology for integral door frame of heavy truck

A heavy-duty truck and overall technology, which is applied in the field of automobile body stamping, can solve problems such as complex shape, high requirements and complexity of stamping process, and achieve the effects of stable quality, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

[0031] Technology of the present invention is:

[0032] (1) Cutting: use shears to cut the original plate into such figure 1 blocks shown.

[0033] (2) Cutting head punching: install the cutting head punching die on the press, and position the cutting head punching with the adjacent side, such as figure 2 shown.

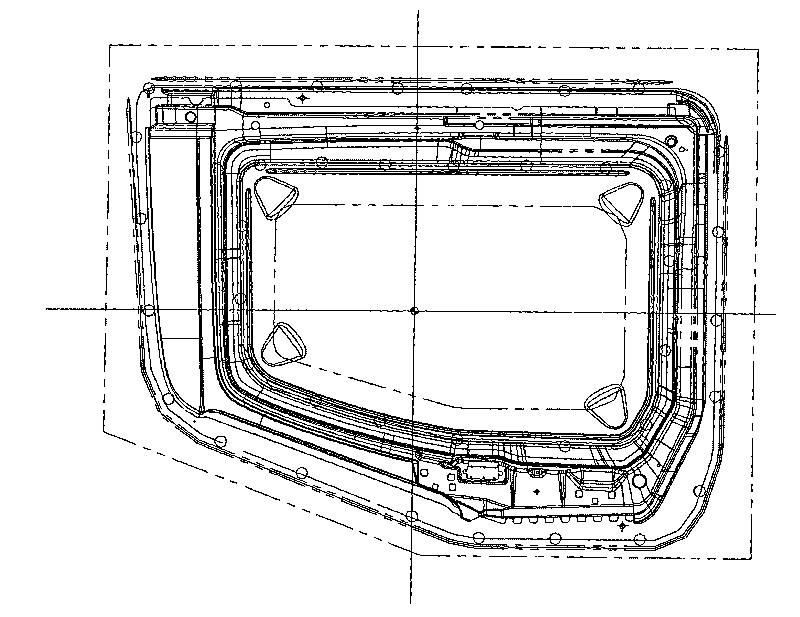

[0034] (3) Drawing: Install the drawing die on the press, and draw it with peripheral positioning, such as image 3 shown.

[0035] (4) Trimming and punching: Install the trimming and punching die on the press, position trimming, punching, flanging and shaping with the inner shape, Figure 4 shown.

[0036] (5) Trimming, punching, flanging, and shaping: install the trimming, punching, flanging, and shaping molds on the press, and use the inner shape to position, trim, and punch holes. Figure 5 shown.

[0037] (6) Flange shaping, side punching, side shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com