Method for positioning mold core and mold shell of hollow blade

A technology of hollow blades and cores, applied in the direction of cores, molds, mold components, etc., can solve problems such as broken cores and eccentric cores, and achieve the effects of large economic benefits, uniform wall thickness, and shortened processing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

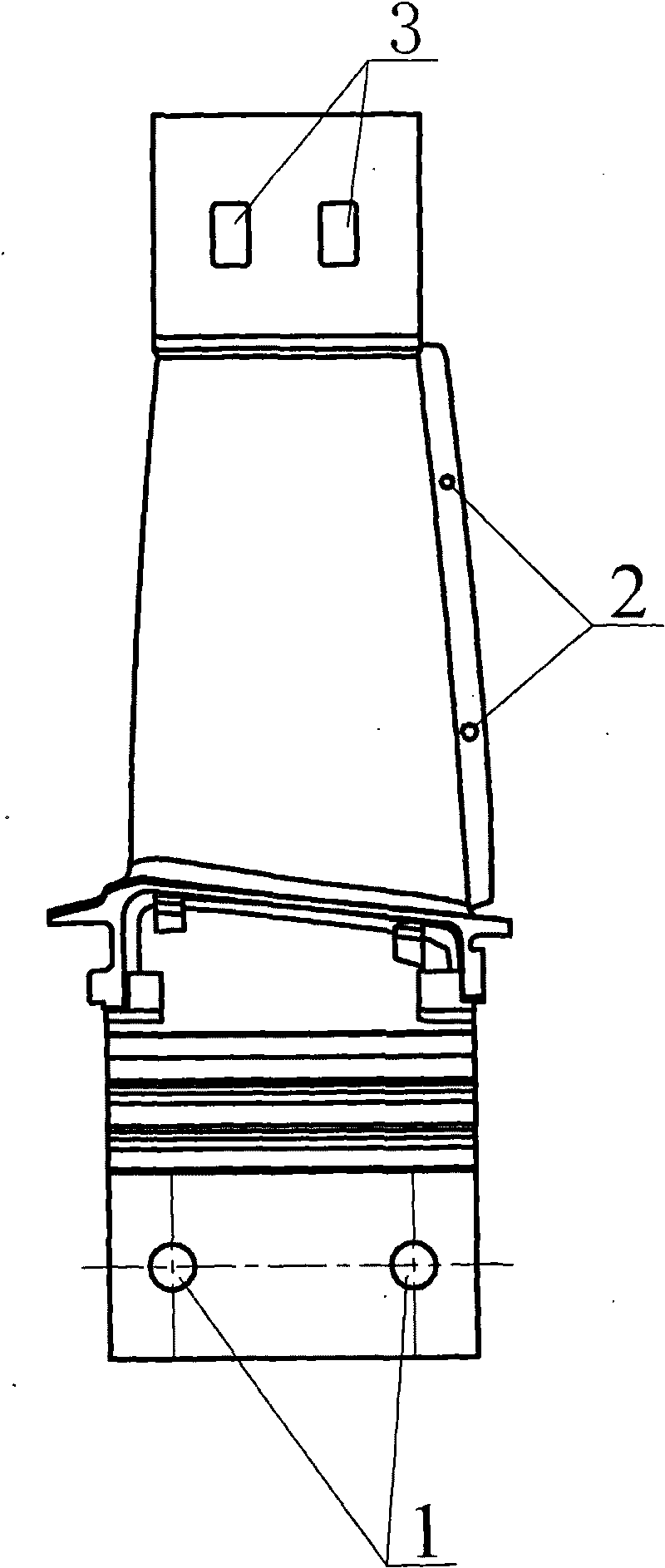

[0023] According to the temperature field distribution characteristics of the high-turbulence blade ceramic core and shell during the directional solidification process, as well as the analysis of physical characteristics such as the linear expansion of the core and the shell itself, the point and surface direct contact method is adopted for the positioning of the ceramic core.

[0024] The blade tip extension section is provided with a blade tip positioning point, and the blade tip extension section where the blade tip positioning point is located is used as a fixed end, which adopts a direct surface contact type; the exhaust side is coated with a free end, and two positioning points are made on the free end, here The core and the shell adopt the point contact type; the extension of the tenon tooth also adopts point positioning, and two tower positioning points are made on the tenon tooth extension section, and the point contact type is adopted; the positioning method of the co...

Embodiment 2

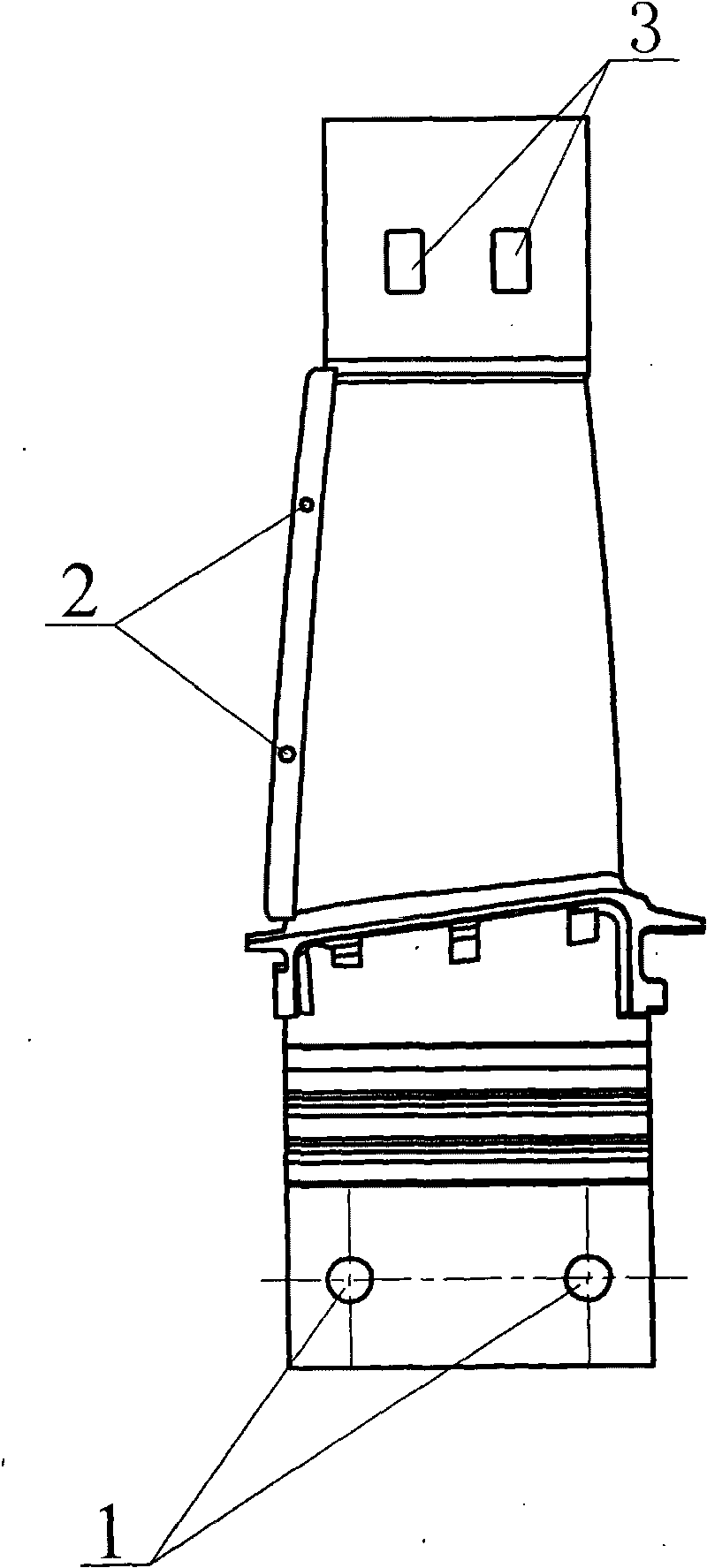

[0033] According to the temperature field distribution characteristics of the high-turbulence blade ceramic core and shell during the directional solidification process, as well as the analysis of physical characteristics such as the linear expansion of the core and the shell itself, the point and surface direct contact method is adopted for the positioning of the ceramic core.

[0034] The blade tip extension section is provided with a blade tip positioning point, and the blade tip extension section where the blade tip positioning point is located is used as a fixed end, which adopts a direct surface contact type; the exhaust side is coated with a free end, and two positioning points are made on the free end, here The core and the shell adopt the point contact type; the extension of the tenon tooth also adopts point positioning, and two tower positioning points are made on the tenon tooth extension section, and the point contact type is adopted; the positioning method of the co...

Embodiment 3

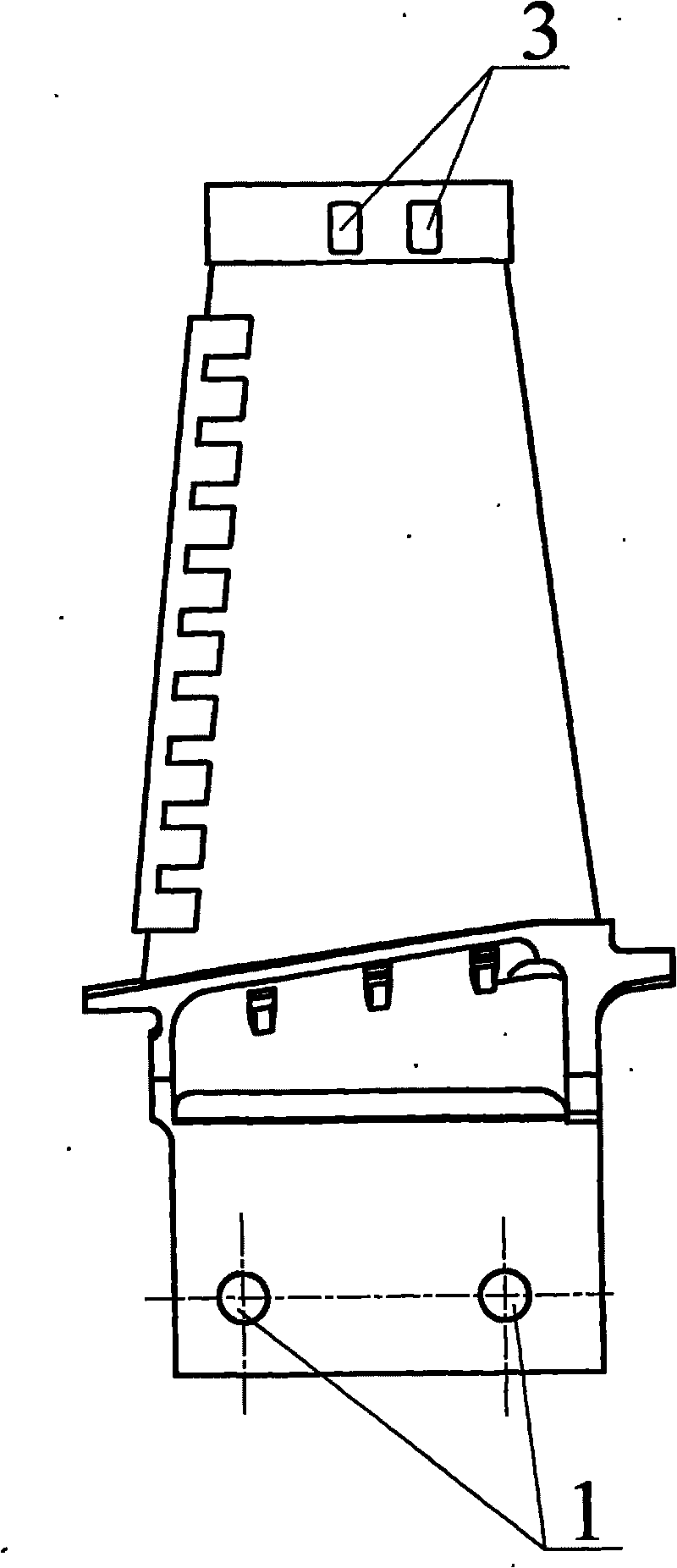

[0043] According to the temperature field distribution characteristics of the high-turbulence blade ceramic core and shell during the directional solidification process, as well as the analysis of physical characteristics such as the linear expansion of the core and the shell itself, the point and surface direct contact method is adopted for the positioning of the ceramic core.

[0044]The blade tip extension section is provided with a blade tip positioning point, and the blade tip extension section where the blade tip positioning point is located is used as a fixed end, which adopts a direct surface contact type; the exhaust side is coated with a free end, and two positioning points are made on the free end, here The core and the shell adopt the point contact type; the extension of the tenon tooth also adopts point positioning, and two tower positioning points are made on the tenon tooth extension section, and the point contact type is adopted; the positioning method of the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com