Assembly machine for mechanical seal of rubber bellows

A technology of mechanical seals and bellows, which is applied in the field of rubber bellows mechanical seal assembly machines, can solve the problems that are not conducive to mass assembly of rubber bellows mechanical seals, consume a lot of effort, and have low assembly efficiency, achieving high assembly efficiency, The effect of simple assembly and high assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

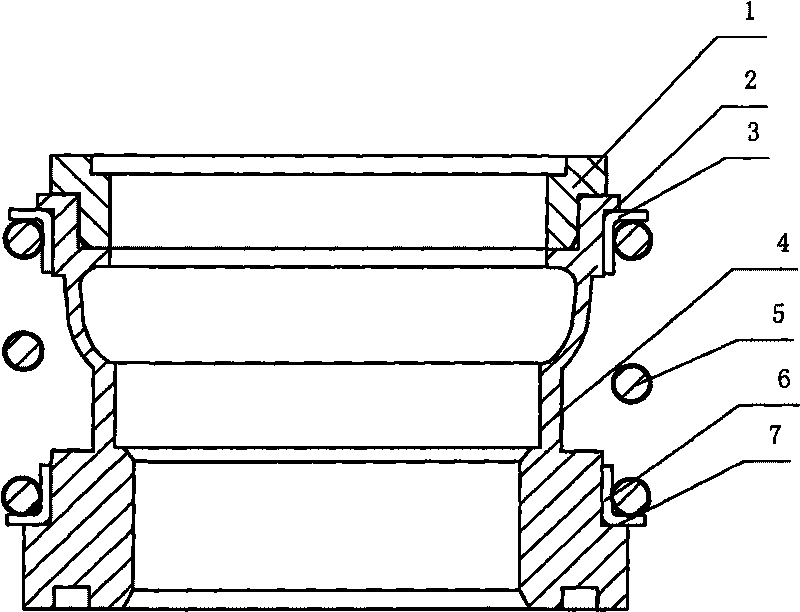

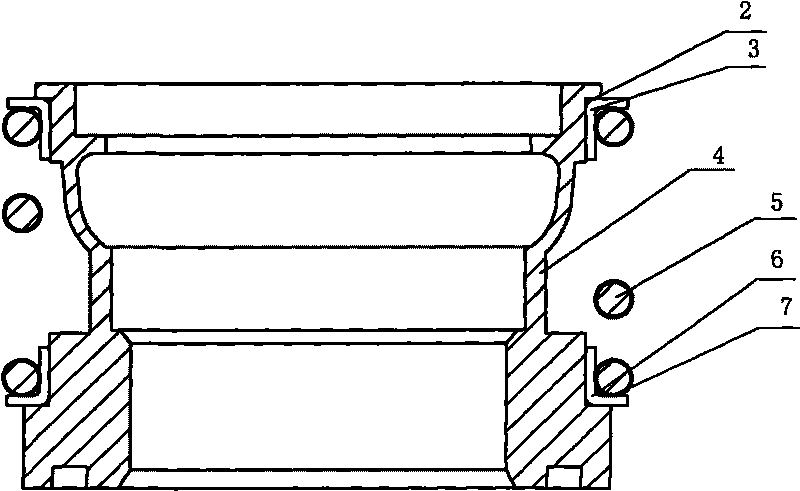

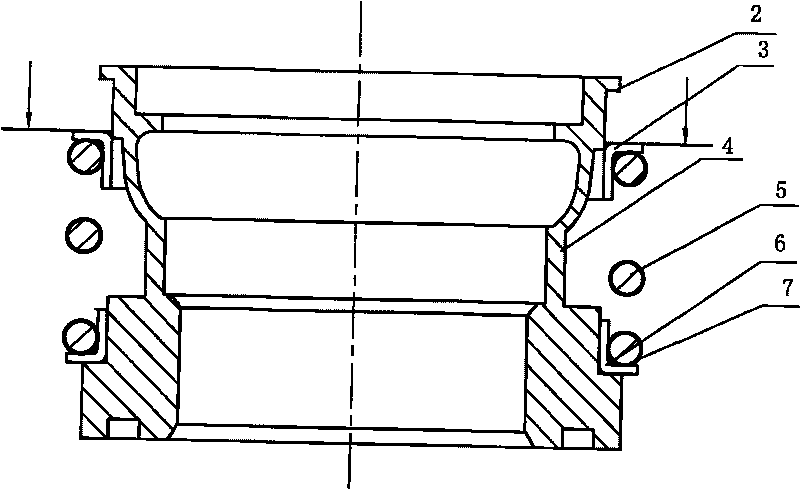

[0033] Such as image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Picture 8 Shown.

[0034] The rubber bellows mechanical seal assembly machine of the present invention includes a working panel 8 and a pressure head device. A positioning mandrel 16 capable of placing the rubber bellows mechanical seal is fixedly installed on the working panel 8 and the pressure head device is located at the positioning Above the mandrel 16, and the axis of the positioning mandrel 16 coincides with the center line of the indenter 13 in the indenter device, and the frame under the indenter device is also provided with a pressure that can move the indenter device vertically. Tightening the cylinder 17; the working panel 8 is also provided with a straight sliding groove 26 centered on the axis of the positioning mandrel 16, and the straight sliding groove 26 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com