Carbon nano tube-doped ferric oxide three-dimensional nanometer material and preparation method thereof

A three-dimensional nanometer and carbon nanotube technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of poor crystallinity of nanomaterials, increased cost, difficult template removal, etc., to achieve the effect of broadening the field of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

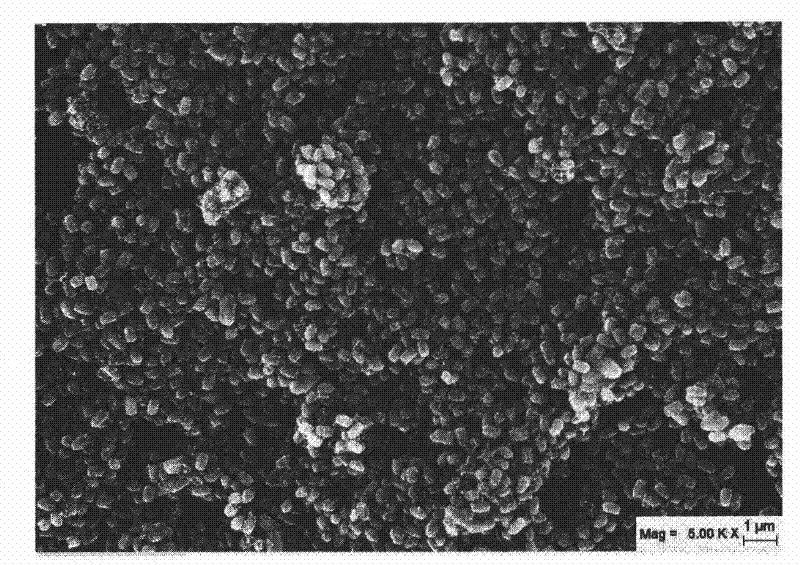

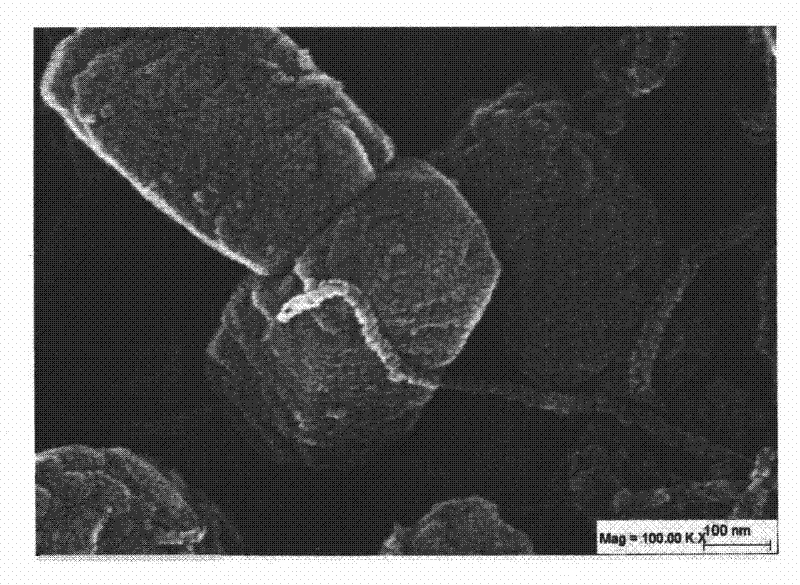

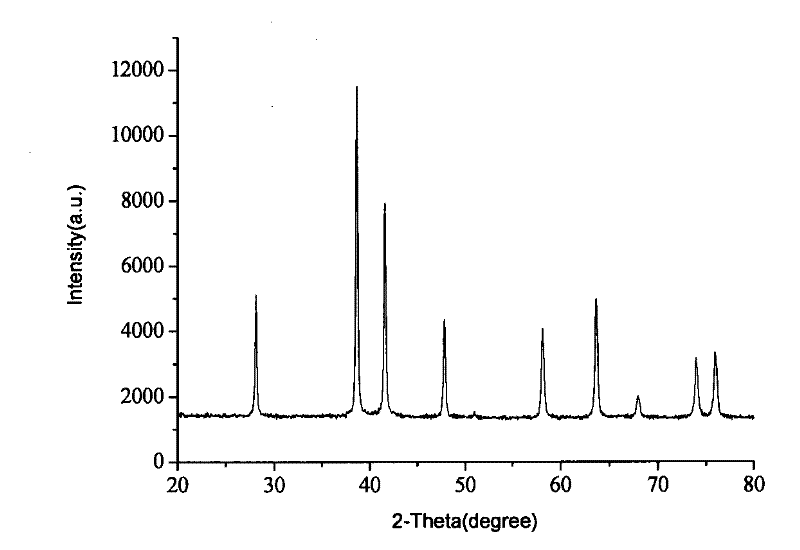

[0014] Add 0.05g of acidified carbon nanotubes to 24ml of 0.3M ferric nitrate solution in 1,4 butanediol and 24ml of 0.5M ethylenediamine in 1,4 butanediol solution, mix well and pour into 60ml In the polytetrafluoroethylene bushing, the filling degree is 80%. Put the sealed polytetrafluoroethylene bushing into a hydrothermal kettle at 200°C for 12 hours. After cooling to room temperature, filter and dry to obtain a length of about 0.25 μm, cuboid carbon nanotubes with a width of about 0.15 μm doped with iron oxide.

Embodiment 2

[0016] Add 0.01g of acidified carbon nanotubes to 24ml of 0.4M ferric chloride in 1,4 butanediol solution and 24ml of 0.7M ethylenediamine in 1,4 butanediol solution, after uniform mixing, pour into the In a 60ml polytetrafluoroethylene bushing, the filling degree is 80%. Put the sealed polytetrafluoroethylene bushing into a hydrothermal kettle at 200°C for 10 hours. After cooling to room temperature, filter and dry to obtain a length approx. 0.3 μm, cuboid-shaped carbon nanotubes with a width of approximately 0.1 μm doped with iron oxide.

Embodiment 3

[0018] Add 0.01g of acidified carbon nanotubes to 24ml of 0.5M ferric sulfate in 1,4 butanediol solution and 24ml of 0.8M ethylenediamine in 1,4 butanediol solution, mix well and pour into 60ml In the polytetrafluoroethylene bushing, the filling degree is 80%, put the sealed polytetrafluoroethylene bushing into a hydrothermal kettle at 180°C for 15 hours, cool to room temperature, filter, and dry to obtain a length of about 0.1 μm, cuboid-shaped carbon nanotubes with a width of approximately 0.08 μm doped with iron oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com