Method for preparing magnesium hexaborate

A technology of magnesium hexaborate and boric acid is applied in the field of preparation of inorganic chemical raw materials, which can solve the problems of slow reaction speed and low hydration rate, and achieve the effects of improving yield, improving reaction rate and simple process.

Inactive Publication Date: 2011-01-05

HENAN POLYTECHNIC UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, magnesium borate can be synthesized by boric acid and unactivated magnesium oxide. Due to the low hydration rate of unactivated magnesium oxide, boric acid reacts with it very slowly at room temperature, and there are a large amount of unreacted magnesium oxide in the product.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

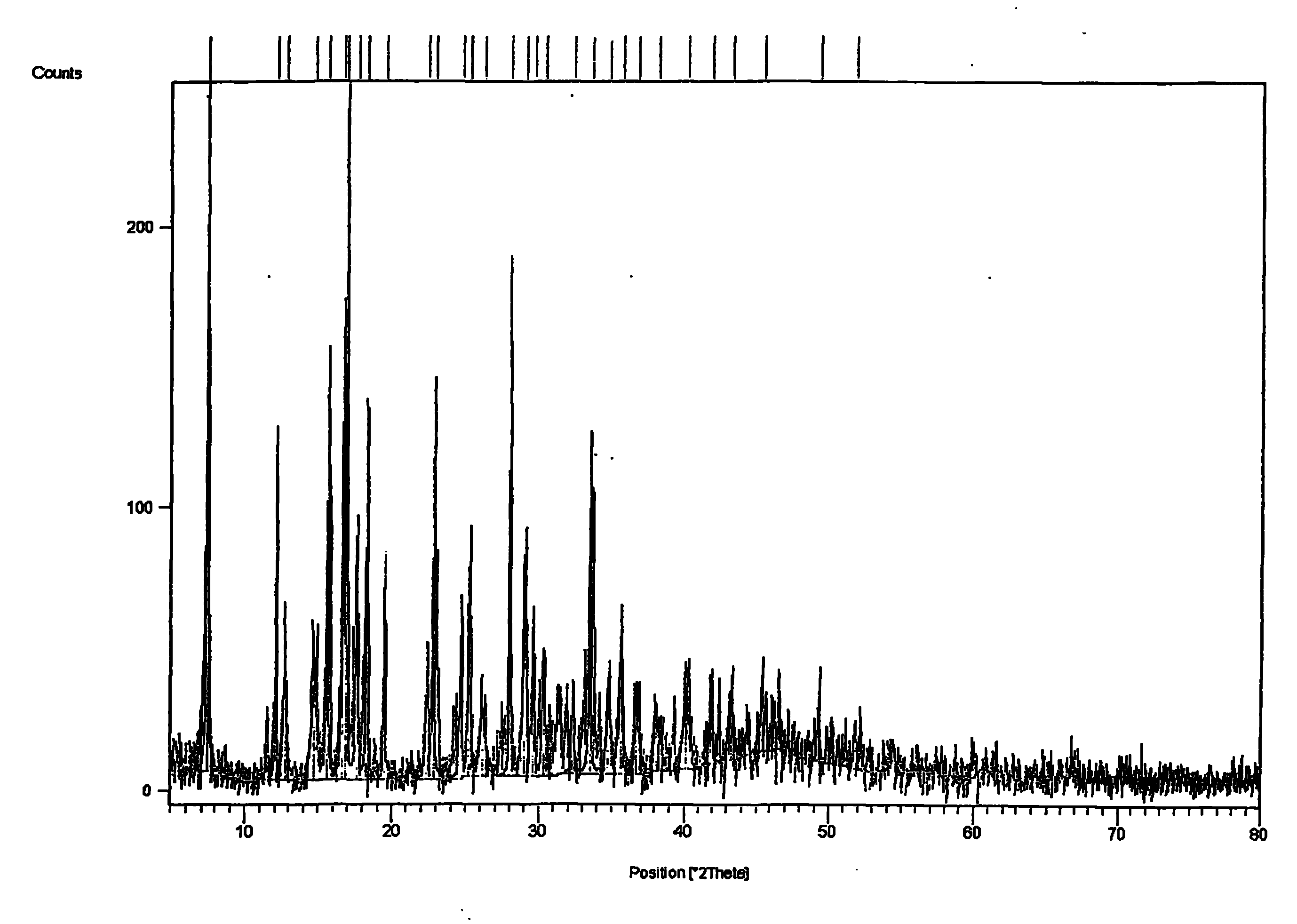

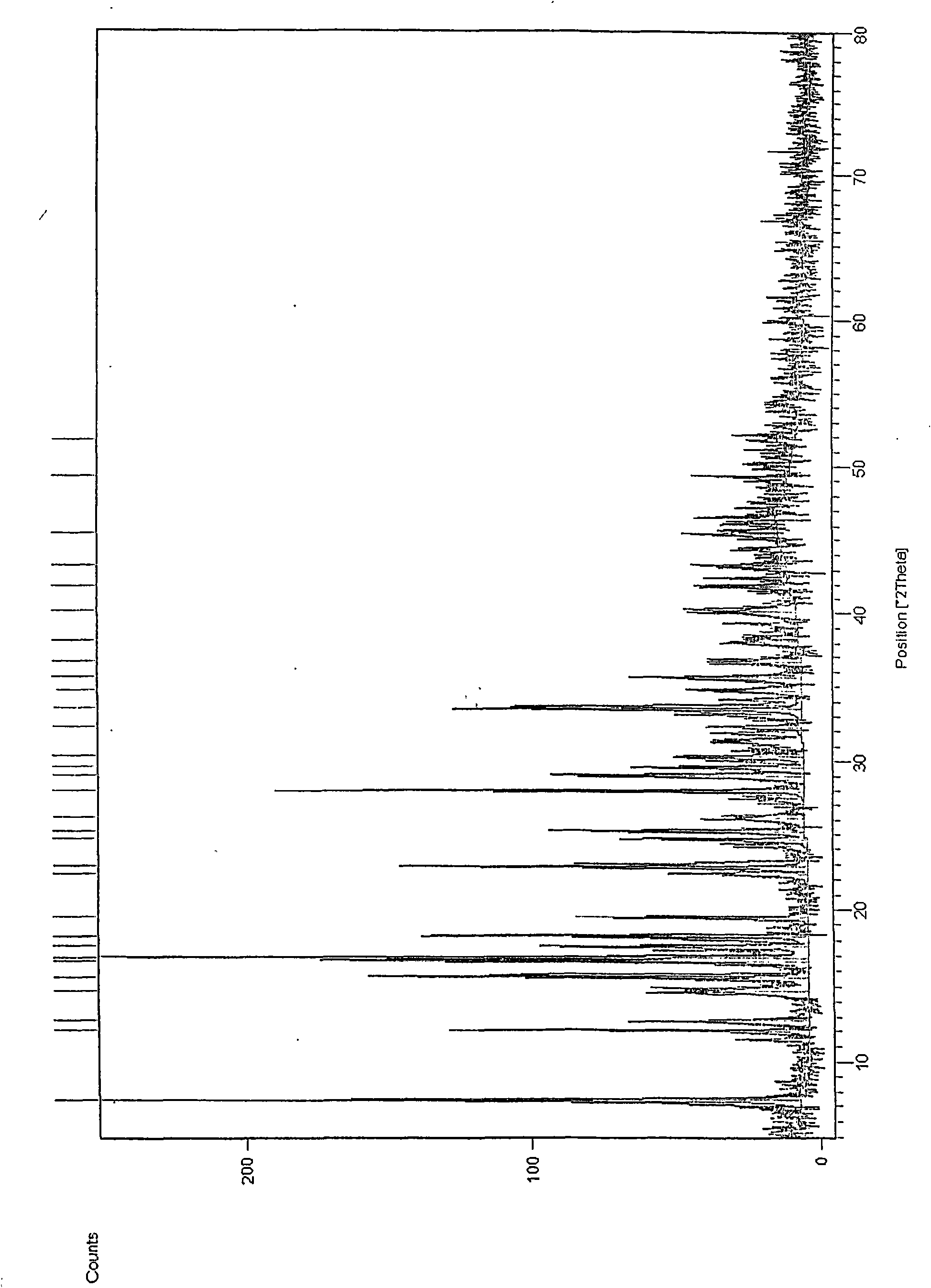

The invention relates to a method for preparing an inorganic chemical raw material, in particular to a method for preparing magnesium hexaborate, which particularly comprises the following steps: (2) burning basic magnesium carbonate or magnesium oxide for 2.5 to 6 hours at a temperature of between 600 and 1,000 DEG C to obtain activated magnesium oxide; (2) mixing the activated magnesium oxide with boric acid and water in a mass ratio of 1:3-9:60-165, stirring the mixture for 3 to 7 hours, standing the mixture for 1 to 6 hours, and filtering the mixture to obtain a clear filtrate; (3) standing the clear filtrate for 10 to 22 hours, then stirring, heating and concentrating the clear filtrate, and cooling the clear filtrate for crystallization; and (4) filtering the mixture of crystalline precipitates generated in the step (3), washing a crystal mass, and drying the crystal mass for 1 to 3 hours at a temperature of between 100 and 160 DEG C to obtain the magnesium hexaborate. The method has the advantages that: 1, the activated magnesium oxide is used as the raw material to improve the reaction rate and the yield and avoid a large amount of unreacted magnesium oxide; and 2, becausethe process is simple, the method can be used for large-scale industrial production.

Description

A kind of preparation method of magnesium hexaborate Technical field: The invention relates to a preparation method of inorganic chemical raw materials, in particular to a preparation method of magnesium hexaborate. Background technique: Boron ore is an important resource in our country, and it has a wide range of uses in the fields of industry, agriculture, metallurgy, medicine, national defense, textiles and high-tech. It is used as micro-fertilizer and pesticide in agriculture; it is used as a metal additive in metallurgy to improve the performance of steel and alloys; in the defense industry, boron fibers made of element boron have high strength and are used as aerospace materials, borohydride compounds It can also be used as a high-energy material for rockets and missiles; in the field of medicine, boron compounds can selectively destroy and inhibit cancer cells and treat brain tumors. At the same time, boron compounds are widely used as nonlinear optical materials, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B35/12

Inventor 张爱芸郑娟白玉花

Owner HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com