Combined semi-directly driven wind-powered speed increasing box

A combined, semi-direct drive technology, applied in wind power generation, transmission boxes, wind turbines, etc., can solve the problem of maintenance. The entire wind power speed-up box must be disassembled from the top of the tower before repairing and increasing the speed-up box. The burden of the manufacturer, the difficulty of equipment transportation and installation, etc., to achieve the effect of shortening the mechanical transmission chain, improving the overall performance, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

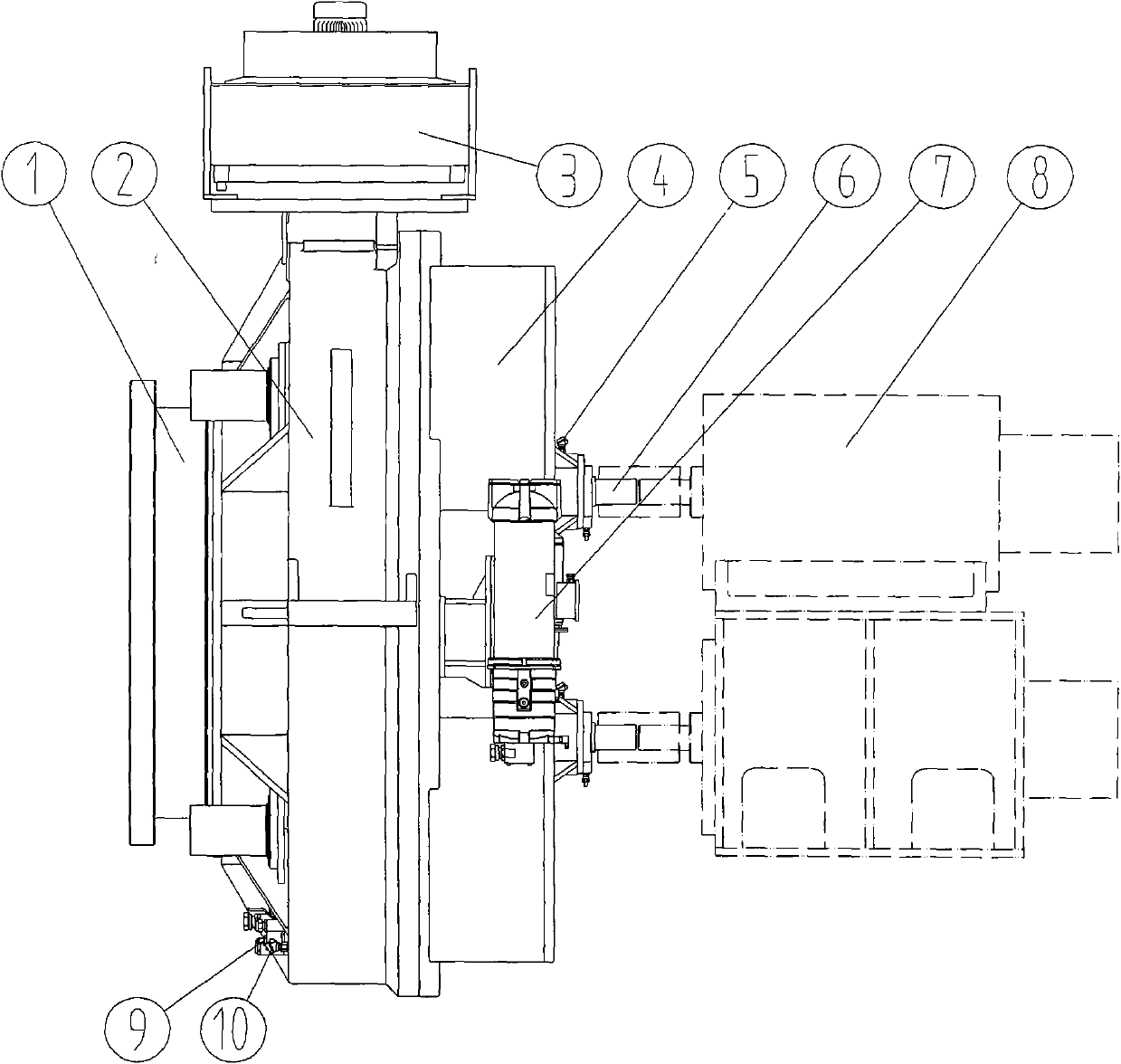

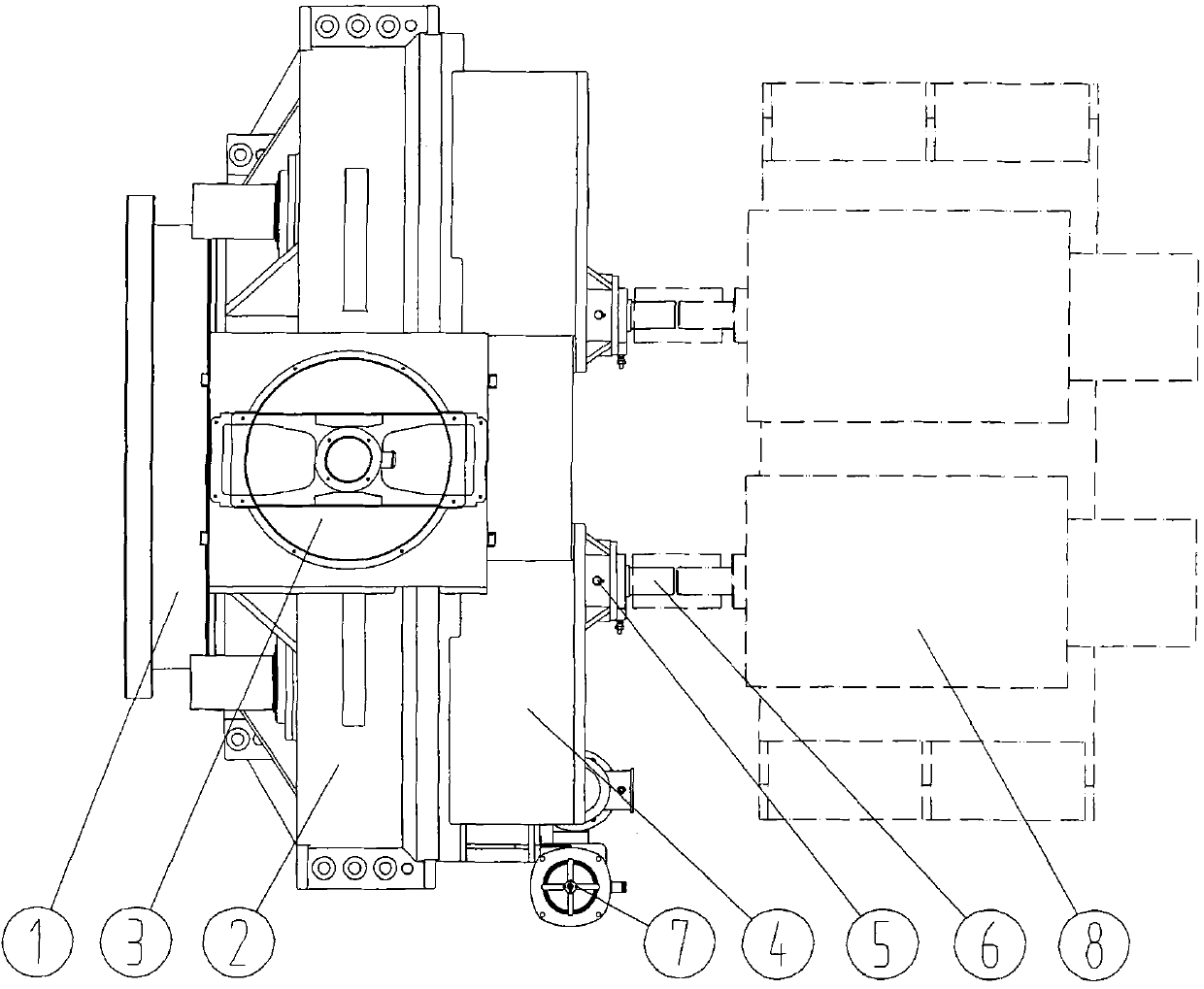

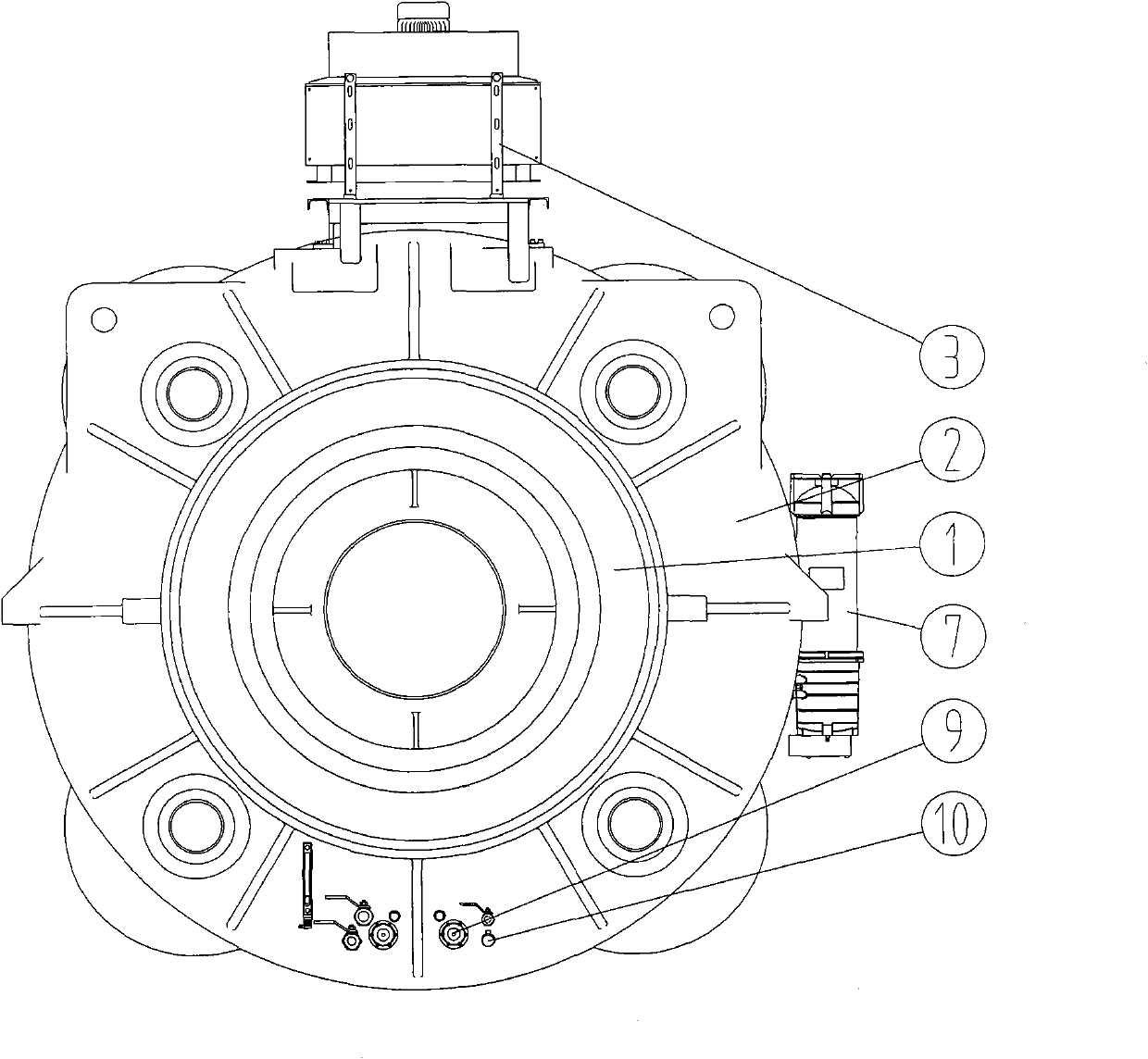

[0037] see Figure 1 to Figure 5 , the combined semi-direct drive wind power gearbox in this embodiment is composed of an air cooling device 3, an oil supply filter device 7, a temperature control device, a primary speed-up body and a secondary speed-up body, wherein the temperature control device includes a bearing Temperature sensor 5, electric heater 9 and oil temperature sensor 10.

[0038] The first-stage speed-increasing body in this embodiment includes a coupling body 1, a primary box body 2, a combined tapered roller bearing 11, a large ring gear 13 and four gear shafts 14 with brake discs 12, wherein the coupling body 1 It is a hollow barrel structure, which greatly reduces the overall weight of the primary speed-increasing body. The combined tapered roller bearing 11 in this embodiment is installed in the primary box 2, the inner ring of the combined tapered roller bearing 11 can rotate, the large ring gear 13 is located in the primary box 2, and the connecting body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com