Capillary melting point apparatus with heat-free hysteresis effect of uniform temperature field

A technology of thermal hysteresis and capillary, which is applied in the direction of instruments, thermometers, scientific instruments, etc., can solve the problems of large errors in the melting point determination system and errors in the melting point determination system, and achieve the effect of eliminating thermal hysteresis system errors and facilitating calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

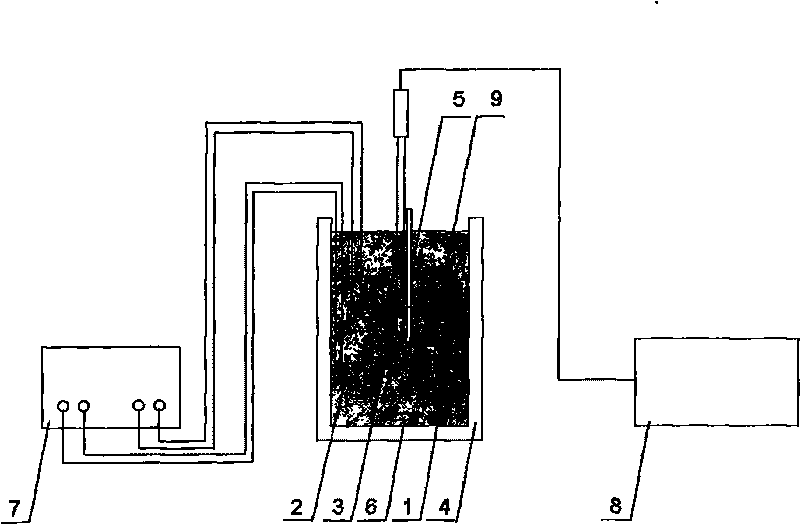

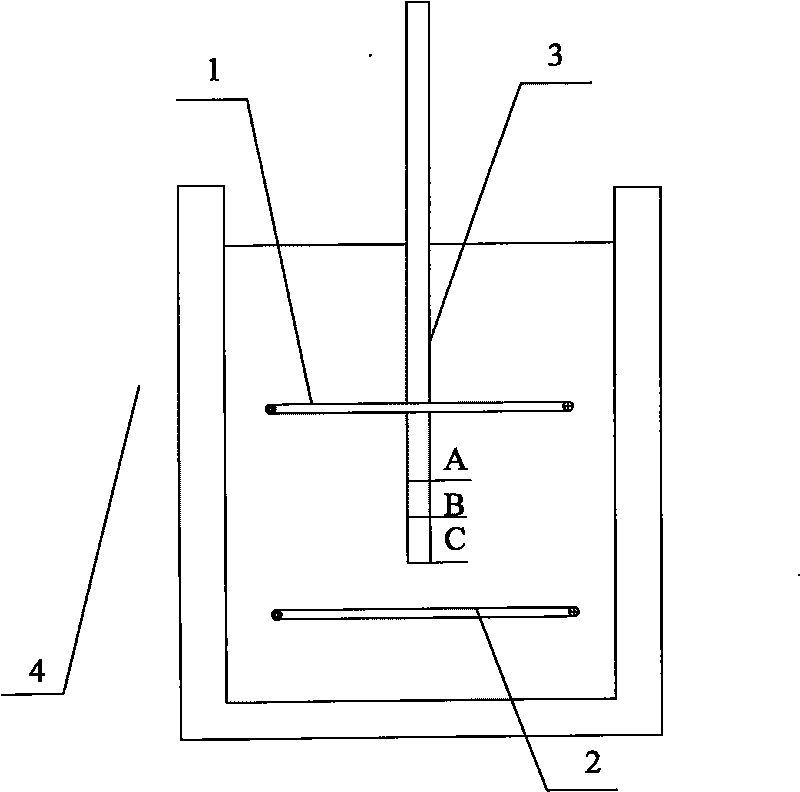

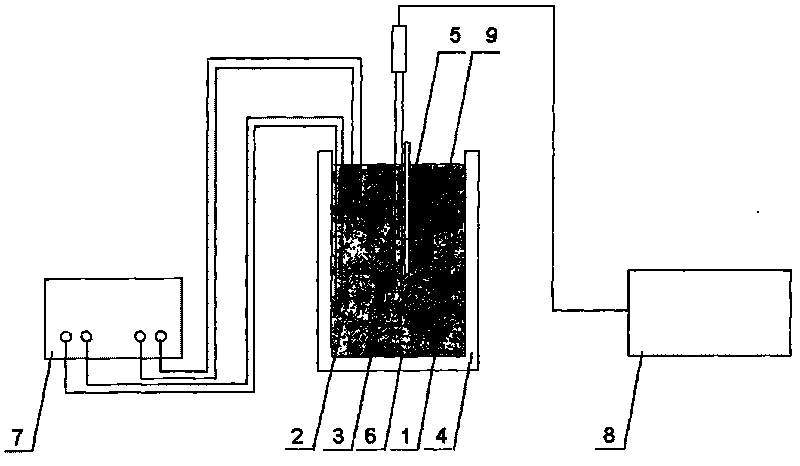

[0014] Such as figure 1 A capillary melting point apparatus with a uniform temperature field and no thermal hysteresis is shown, which includes two parts: a heating system and a temperature measuring system.

[0015] The heating system includes an upper heating wire 1 and a lower heating wire 2 for heating, and a DC stabilized voltage power supply 7 that provides current to the heating wire; a vacuum insulated cup 4 made of quartz as a heating system container is used as a heating medium The methyl silicone oil 9, and the stirring bar 6 for stirring to make the temperature of the system uniform.

[0016] The temperature measurement system includes a Pt100 industrial platinum resistance thermometer 3 for temperature measurement, and a high-precision digital voltmeter 8 for measuring the resistance of the platinum resistance thermometer. The glass capillary 5 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com