Rigid integral dropper of overhead contact line equipment of electrified railway

An electrified railway and catenary technology, applied in the direction of overhead lines, etc., can solve the problems of hanging string ablation, poor current-carrying state, burning loss, etc., to prevent electrical corrosion, overcome the contact line dancing with the wind, and eliminate potential poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

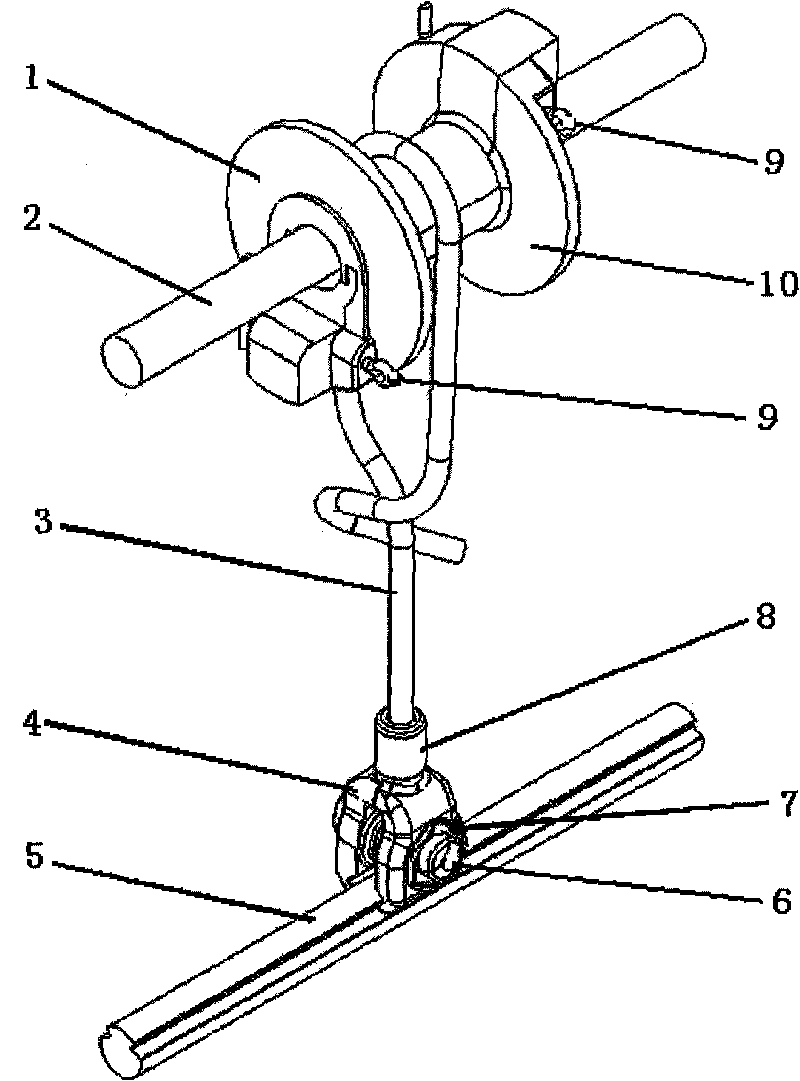

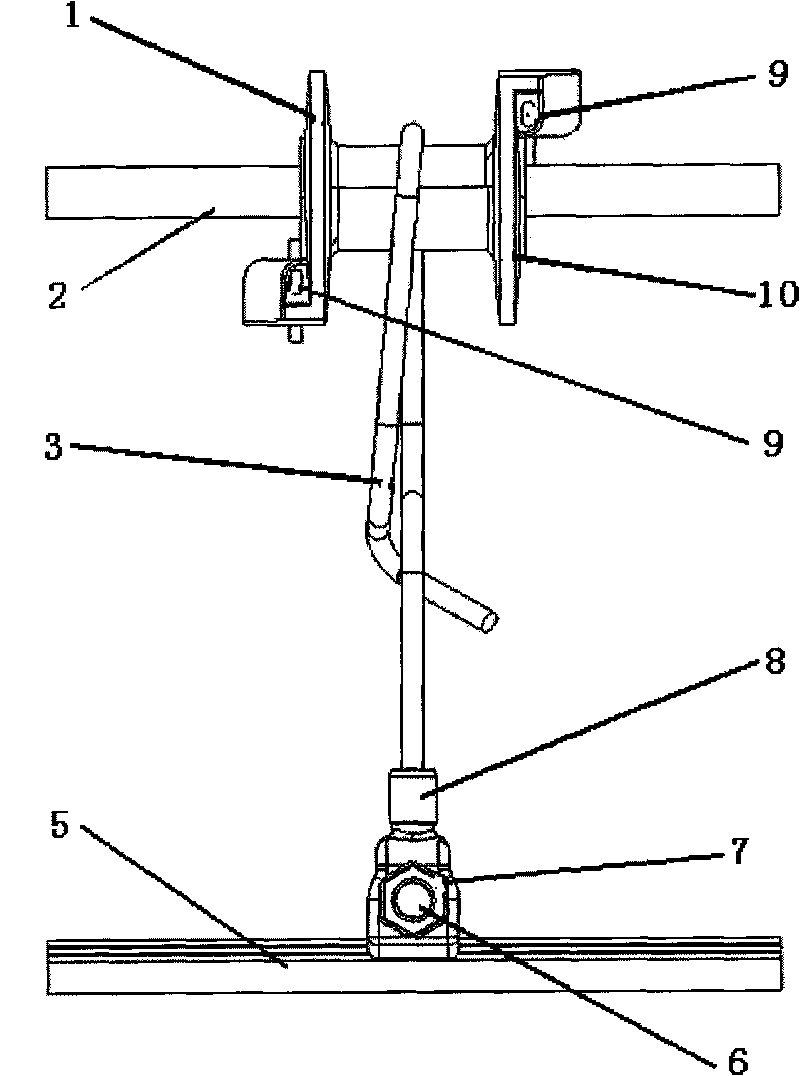

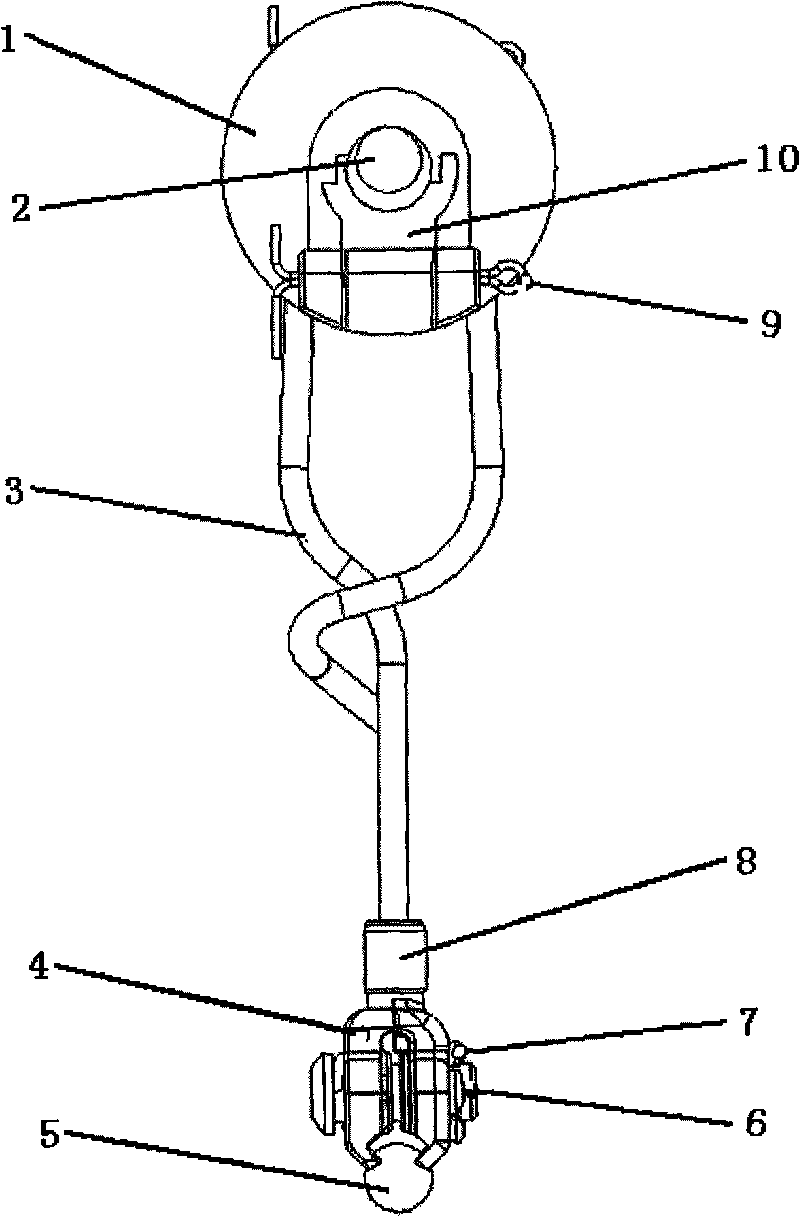

[0018] The structure of the rigid integral hanging string of the present invention, such as figure 1 , figure 2 and image 3 shown. It includes an "I"-shaped sleeve assembled from the sleeve A piece 1 and the sleeve B piece 10. Sleeve A piece 1 and sleeve B piece 10 are saddle-shaped structures, with semicircular grooves along the axial direction, discs are respectively arranged at one end, and a groove is respectively opened on the discs along the radial direction. They respectively communicate with the semicircular grooves in the axial direction of sleeve A piece 1 and sleeve B piece 10. Two protrusions are respectively arranged on the outer surfaces of the discs on both sides of the groove, and there are holes on the protrusions. Two circular through holes, the two circular through holes are located on the same axis, forming a one-to-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com