Shockproof corrugated tube sight glass

A technology of bellows and sight glass, applied in the direction of pipe components, pipes/pipe joints/fittings, expansion compensation devices for pipelines, etc., can solve problems such as crushing, improve performance, avoid glass breakage, and improve shock absorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

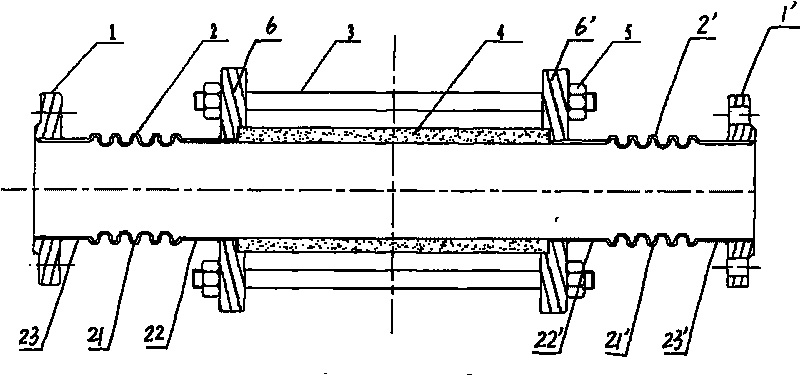

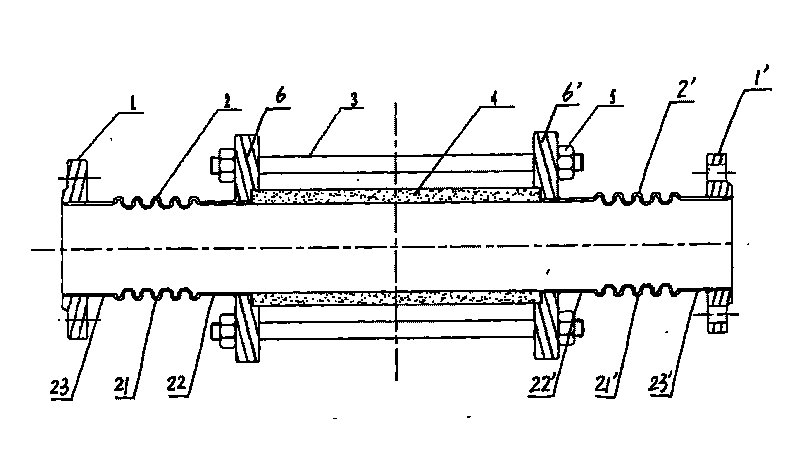

[0020] see figure 1 As shown in the schematic cross-sectional structure of the present invention, a shock-proof bellows sight glass is used in pharmaceutical equipment with high vibration frequency. It consists of two outer flanges 1, 1', two inner flanges 6, 6 ' and a transparent sight glass 4, and the inner flanges 6, 6' and the outer flanges 1, 1' are welded and fixed by metal pipe fittings, wherein:

[0021] The two ends of the transparent sight glass 4 are fixed between two inner flanges 6, 6', the two inner flanges are connected by four parallel studs, the two ends of the studs 3 are fastened by nuts 5, and the The sight glass is fastened between the two inner flanges 6 and 6';

[0022] The metal pipe fittings are bellows 2, 2', which are composed of a corrugated section 21 (21') in the middle and straight pipe sections 22, 23 (22', 23') at both ends, and the straight section at one end of the bellows 2 (2') The pipe section 22 ( 22 ′) is welded and fixed to the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com