Liquid crystal display panel and manufacturing method thereof

A technology of a liquid crystal display panel and a manufacturing method, which are applied in directions such as static indicators, can solve the problems affecting the reaction speed performance of the liquid crystal display panel, etc., and achieve the effects of improving display quality, low light leakage, and good display characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0034] Figure 3A to Figure 3D It is a schematic cross-sectional flow diagram of a manufacturing method of a liquid crystal display panel according to the first embodiment of the present invention.

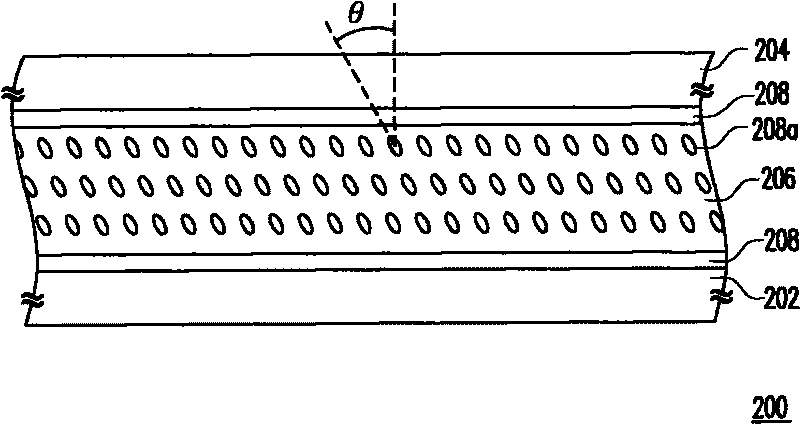

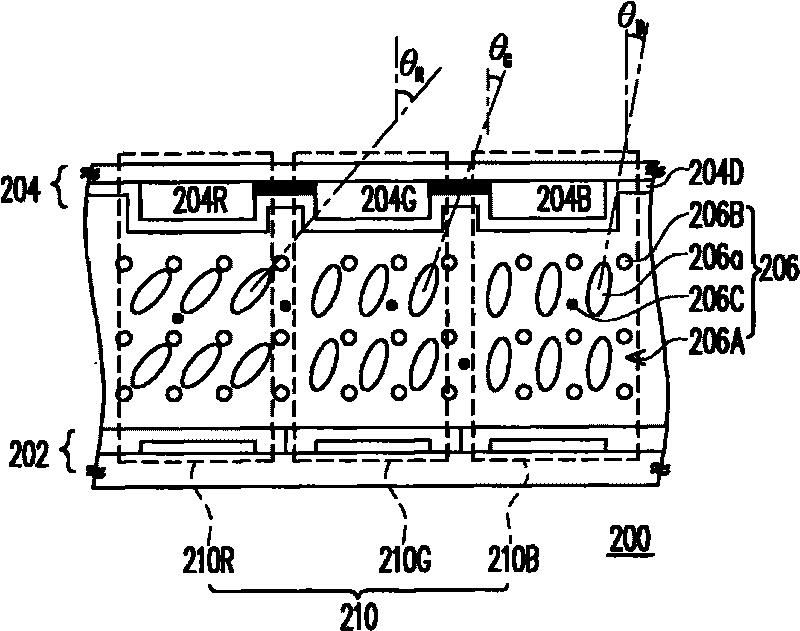

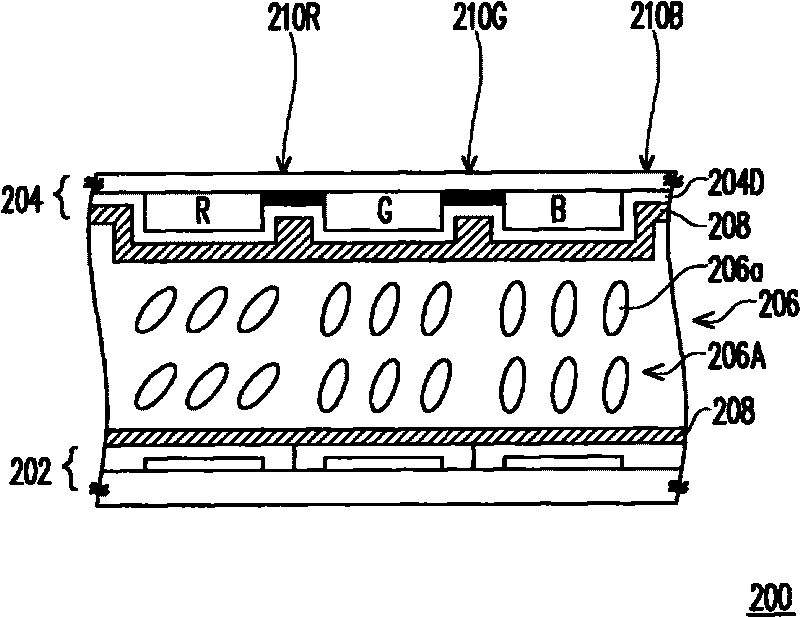

[0035] Please refer to Figure 3A Firstly, a first substrate 202 , a second substrate 204 and a liquid crystal layer 206 sealed between the first substrate 202 and the second substrate 204 are provided. The first substrate 202 is, for example, an active device array substrate, and the second substrate 204 is, for example, a color filter substrate. The first substrate 202 includes a substrate 202A, an active layer 202B and a pixel electrode layer 202C. The second substrate 204 includes a red filter layer 204R, a green filter layer 204G, a blue filter layer 204B and a common electrode 204D. The liquid crystal layer 206 includes a liquid crystal composition 206A, a photosensitive molecular monomer 206B and a photoinitiator 206C. In this way, the first substrate 202, the second su...

no. 2 example

[0041] Figure 4A to Figure 4D It is a schematic cross-sectional flow diagram of a manufacturing method of a liquid crystal display panel according to the second embodiment of the present invention. Wherein, the flow of the manufacturing method of the liquid crystal display panel 200B of this embodiment is similar to that of the first embodiment, but in the manufacturing method of the liquid crystal display panel 200A of this embodiment, it is used to drive the red sub-pixel 210R and the green sub-pixel 210G And the voltage relationship of the blue sub-pixel 210B is different.

[0042] Specifically, Figure 4A with the first embodiment Figure 3A Similar, no more details. Please refer to Figure 4B , in this embodiment, the first voltage V R , the second voltage V G , the third voltage V B For example, the following relationship is satisfied: V R >V G =V B , where the first voltage V R , the second voltage V G , the third voltage V B The range is preferably 8 volt...

no. 3 example

[0046] Figure 5A to Figure 5D It is a schematic cross-sectional flow diagram of a manufacturing method of a liquid crystal display panel according to the third embodiment of the present invention. Wherein, the flow of the manufacturing method of the liquid crystal display panel 200C of this embodiment is similar to that of the first embodiment of the liquid crystal display panel 200A, but in the manufacturing method of the liquid crystal display panel 200C of this embodiment, it is used to drive the red sub-pixel 210R, The voltage relationship between the green sub-pixel 210G and the blue sub-pixel 210B is different.

[0047] Specifically, Figure 5A with the first embodiment Figure 3A Similar, no more details. Please refer to Figure 5B , in this embodiment, the first voltage V R , the second voltage V G , the third voltage V B For example, the following relationship is satisfied: V R =V G >V B , where the first voltage V R , the second voltage V G , the third v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com