rotary drive

A technology of rotating drive device and moving plate, which is applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc., and can solve problems such as easy wear and slipping, complex structure, multi-stage deceleration and gap in transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

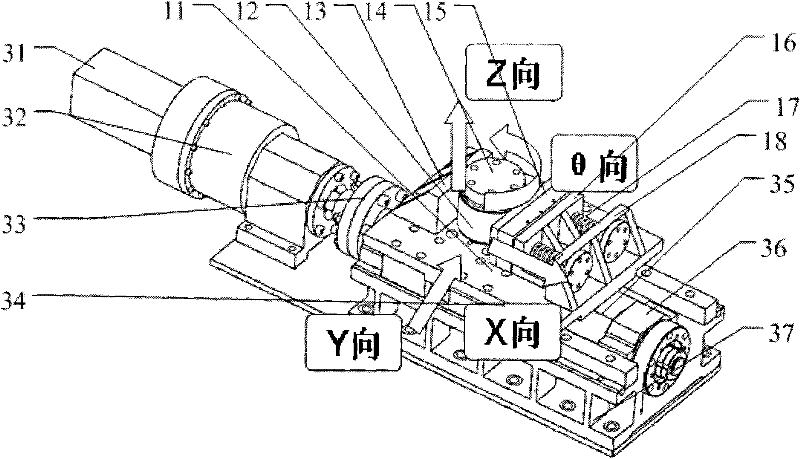

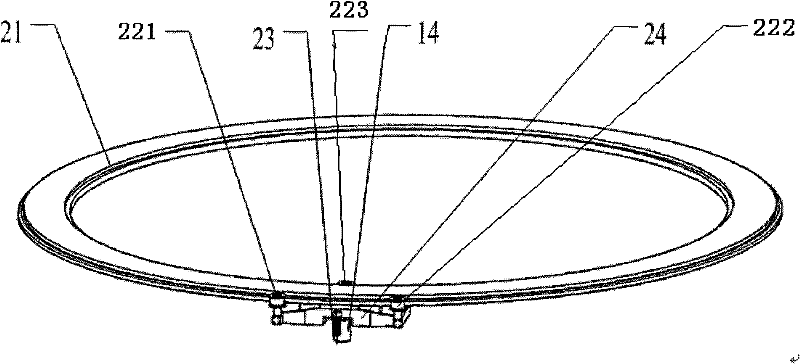

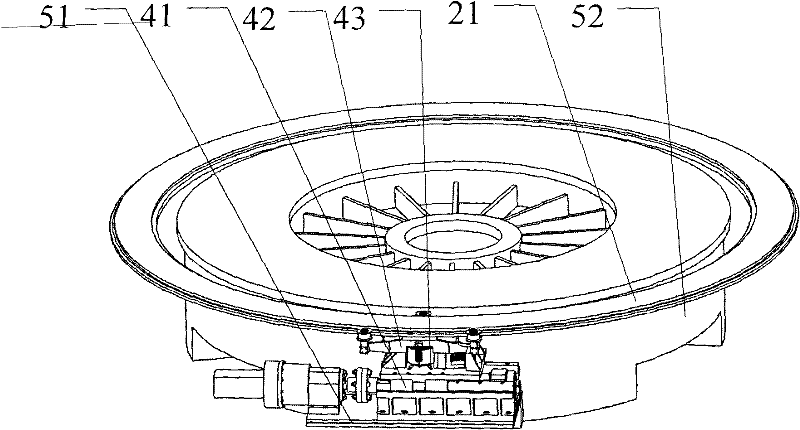

[0020] Such as figure 1 , 3 As shown, the rotary drive device of the present invention includes a linear micro-displacement mechanism 41, a moving plate 11, a push plate 13, a slide plate 15, and rolling elements. Wherein the moving plate 11 , the pushing plate 13 , the sliding plate 15 and the rolling bodies jointly constitute an angular displacement conversion mechanism 43 . The linear micro-displacement mechanism 41 includes a servo motor 31 , a harmonic reducer 32 , a shaft coupling 33 , a rolling guide rail 34 , a ball screw 35 , a bearing seat 36 and a fixed seat 37 . The rolling body adopts a shaft sleeve 12, and a roller or other rolling bodies that can roll can also be used. The moving plate 11 is connected with the linear micro-displacement mechanism 41 and can move linearly along the X direction driven by the linear micro-displacement mechanism 41 . The push plate 13 and the moving plate 11 are integrally structured. The push plate 13 can also be fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com