Crank pin angle control method for machining crankshaft sleeve of low-speed diesel engine for large-scale ship

An angle control and crank pin technology, applied in the direction of the crankshaft, etc., can solve the problems of affecting the accuracy of the angle control, the sliding displacement of the device, and being difficult to adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

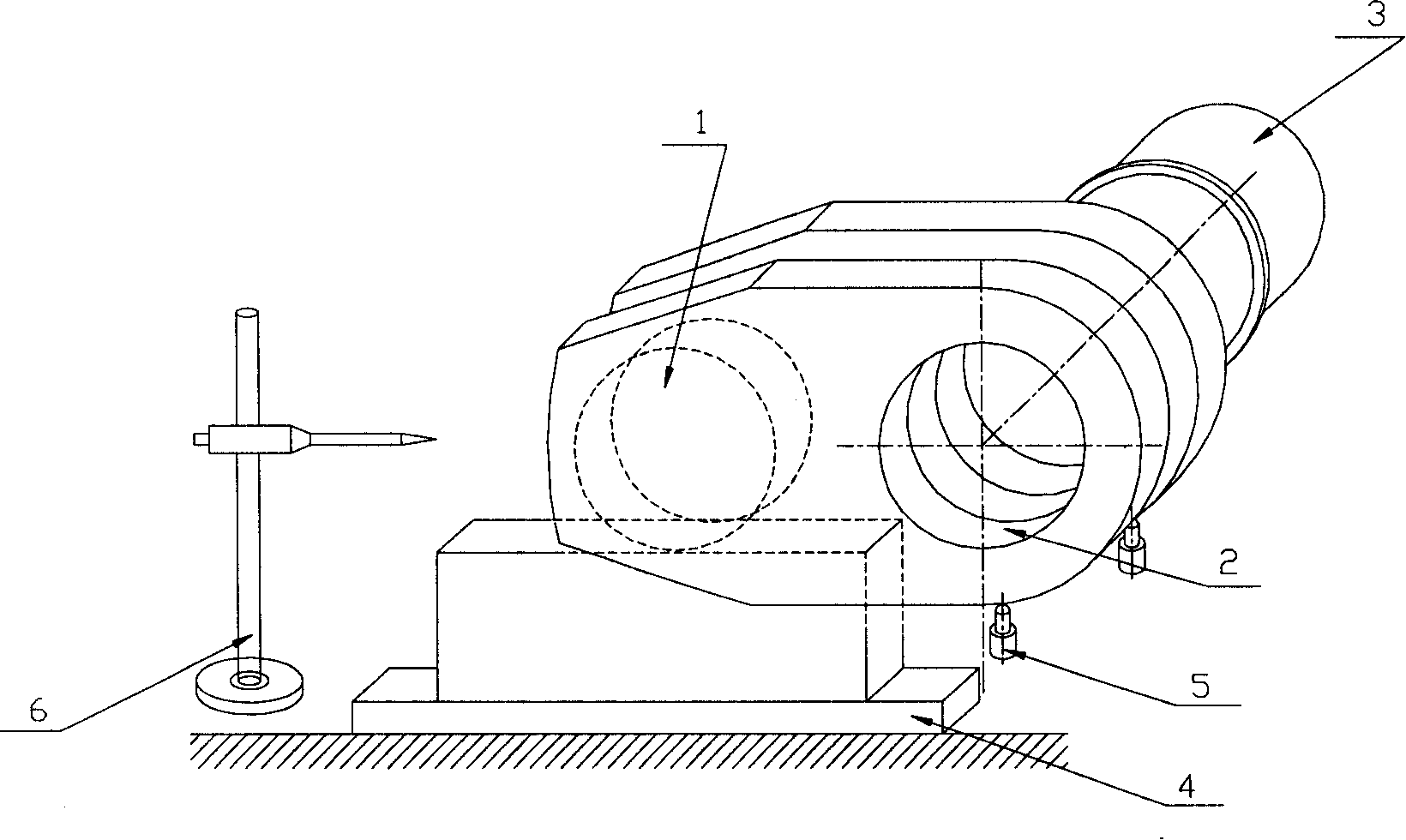

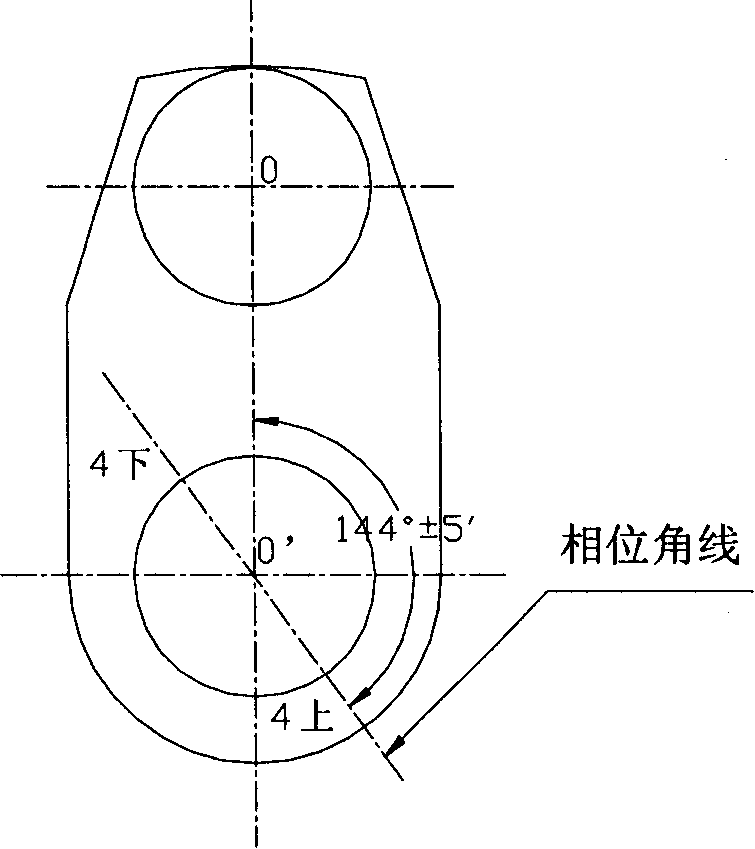

[0013] Such as figure 1 As shown, the present invention, that is, the crank pin angle control method in the processing of the crankshaft red sleeve of a large marine low-speed diesel engine, after the single set of crank throws is completed, the center of each single set of crank throw crank pins 1 is marked, and the crank arm red sleeve hole 2 The center of the main journal 3 and the center connection line and the crank phase angle positioning line of the set main journal 3.

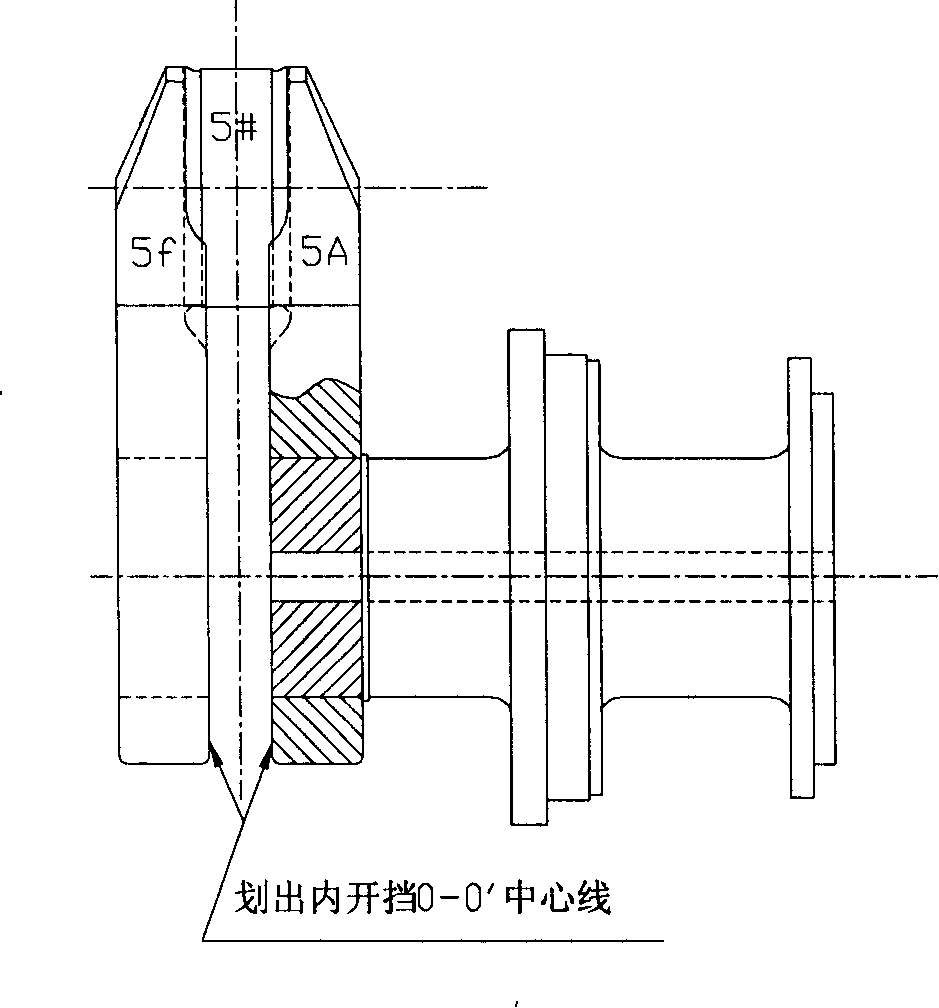

[0014] When drawing the center line, place the outer circle of the crank pin 1 on the pad iron 4 for marking the crank throw, with both sides facing down, and place two oil pump adjustment jacks 5 . The main journal that has been red-sleeved is well cushioned with wooden blocks or flat-top jacks at the outer circle of the non-red-sleeved end, and it is basically placed horizontally. Use the micrometer scale to mark the dial 6 and use the crank pin 1 diameter equal height block to flip up and down sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com