Channel MOS P-N junction Schottky diode structure and manufacturing method thereof

A technology of Schottky diode and channel structure, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low forward voltage drop value, consumption of conductive area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

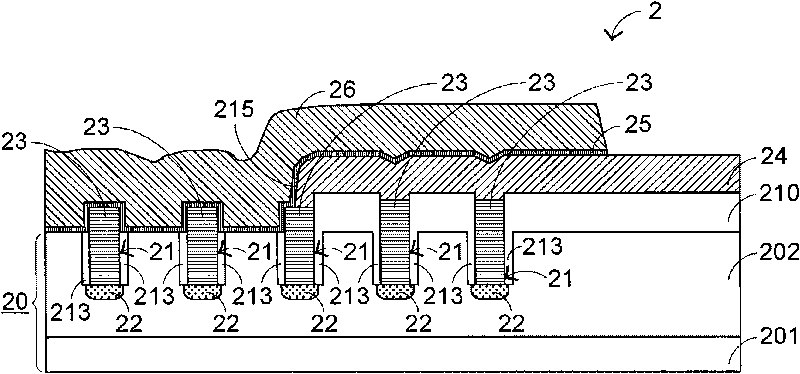

[0101] See figure 2 , which is a schematic diagram of a first preferred embodiment of a trenched metal-oxide-semiconductor P-N junction Schottky diode structure developed by the present invention to improve defects caused by known technical means. We can clearly see from the figure that the trench metal oxide semiconductor P-N junction Schottky diode structure 2 mainly includes a substrate 20, a channel structure 21, an ion implantation region 22, a polysilicon layer 23, an oxide Object layers 213, 210, 24 and metal layers 25, 26, wherein the substrate 20 is composed of a high doping concentration N-type silicon substrate (N+ silicon substrate) 201 and a low doping concentration N-type epitaxial layer (N- epitaxial layer) 202; the channel structure 21 is formed in the substrate 20 and the oxide layer 210, 213; the ion implantation region 22 is formed in the low doping concentration N-type epitaxial layer 202, and is formed in the channel The polysilicon layer 23 in the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com