Energy-saving oil filter with replaceable filter element

An oil filter and filter element replacement technology, applied in the field of filters, can solve the problems of easily affecting the filtration quality, difficult to remove, natural environment hazards, etc., saving oil and a large amount of steel, being conducive to environmental protection, and reducing use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

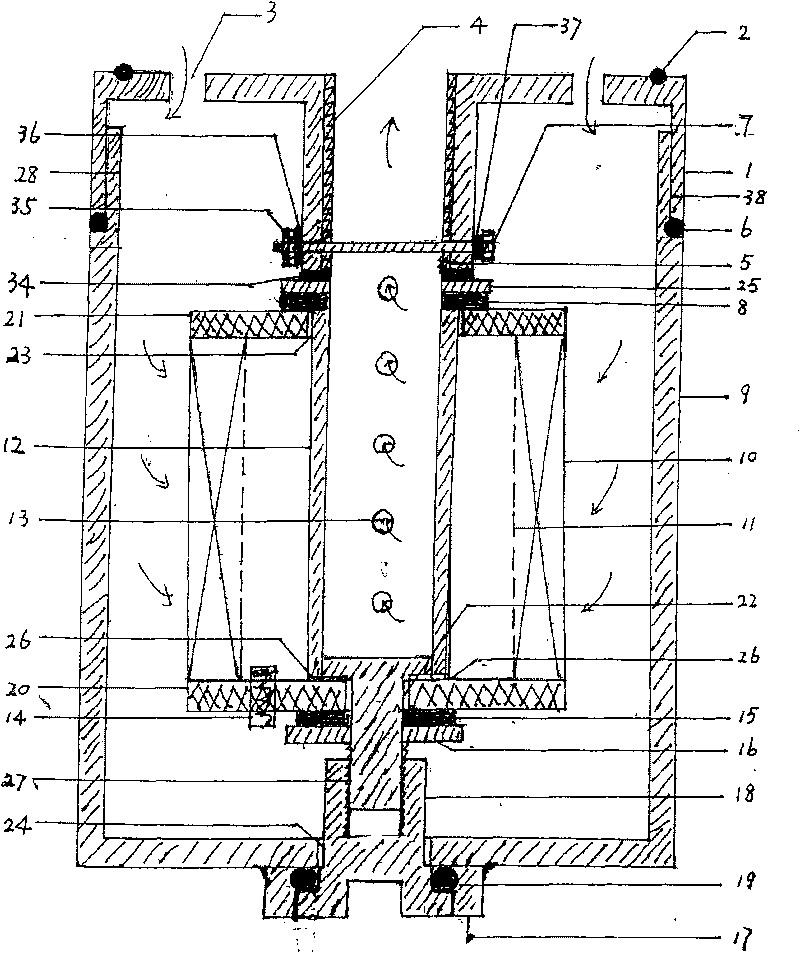

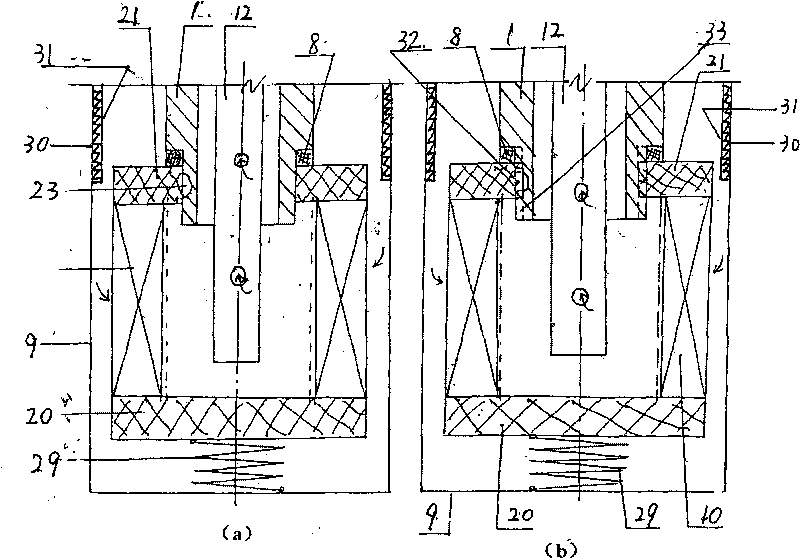

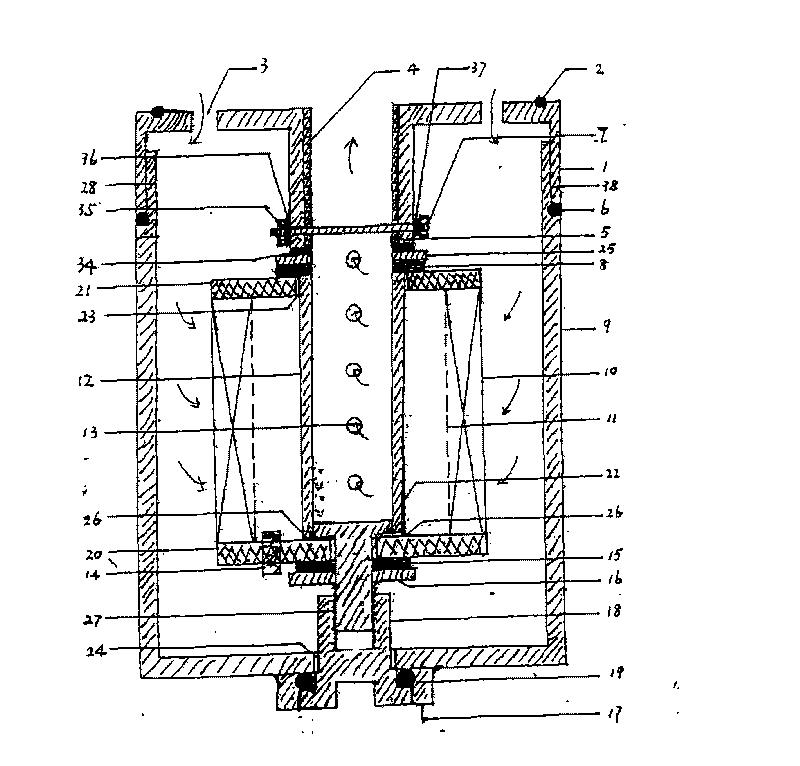

[0012] Further detailed description in conjunction with the accompanying drawings: the arrows in the attached drawings indicate the flow direction of the medium; There is an external spline step (28) on the outer cylinder at the front end, and the thread (27) at the lower end of the oil return pipe of the tubular cylinder is fixed through the special inner square nut (18) and the center hole (24) of the outer cylinder to fix the filter element assembly. Make the outer cylinder assembly (9) and the connecting seat shell (1) close; the connection structure of the detachable connection between the filter element assembly and the related connecting seat shell assembly is the positioning column as follows: the upper and lower parts of the filter element assembly The sealing caps (20) and (21) have upper and lower connection holes (22) and (23) respectively; at the upper threaded part of the connecting seat shell (1) and the thread (4) of the oil seat, the tubular cylinder is returne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com