Multifunctional triaxial core clamping device

A core clamping, multi-functional technology, applied in the field of oilfield exploration and development, can solve the problems of ineffective utilization, single function, high cost, etc., and achieve the effects of saving test costs, reliable technical conditions, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

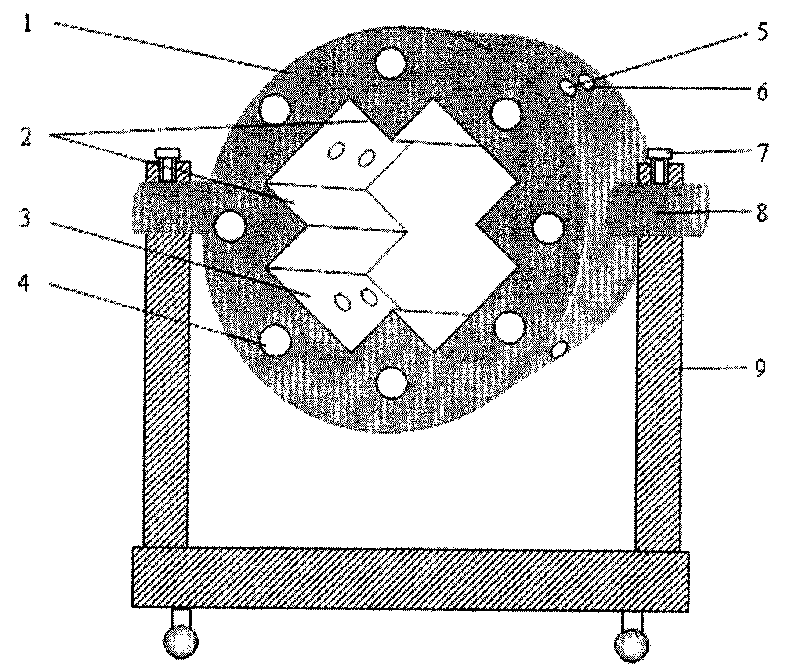

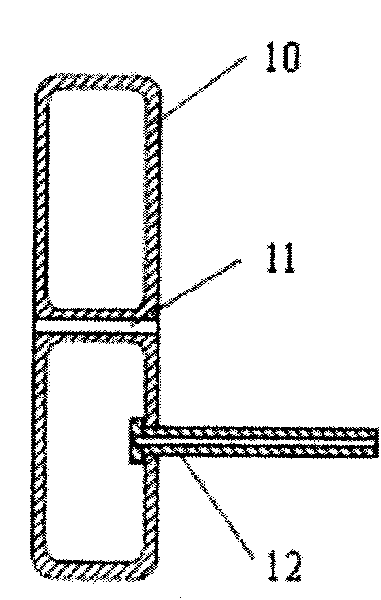

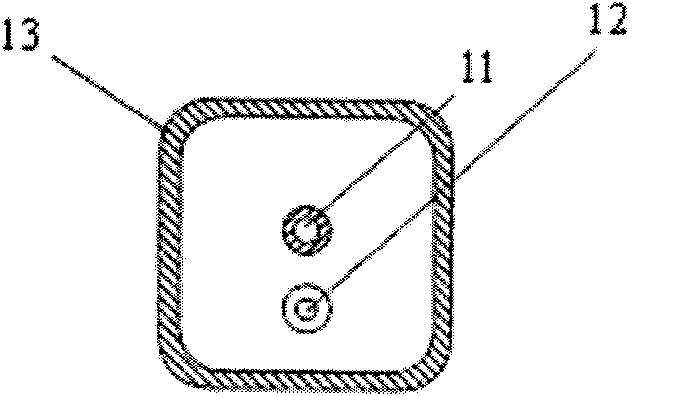

[0028] refer to figure 1 The main body 1 is a metal cylinder with a through hole in the middle along the axial direction. The cross section of the through hole is in the shape of a "ten" as a whole, and four opposite grooves 2 are formed in space for placing the side hydraulic bladder 10. , the depth of the groove 2 is consistent with the thickness of the hydraulic bladder 10 . There are two through holes on the bottom surface 3 of the groove 2, one is located at the center of the bottom surface, which is the test hole 5, and the other is located at the center of the lower half, which is the hydraulic joint hole 6 of the hydraulic bladder. The top surface and bottom surface of the main body are processed with evenly distributed threaded holes 4, and there are two rotating shafts 8 relatively distributed on both sides of the outer cylindrical surface of the main body 1. The axes of the two rotating shafts 8 are on the same line. The axes intersect vertically and form an includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com