Method for measuring thermal expansion coefficient of concrete

A technology of thermal expansion coefficient and measurement method, applied in the direction of material thermal expansion coefficient, etc., can solve the problems of large uncertainty and low accuracy, achieve good repeatability, meet the accuracy requirements, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

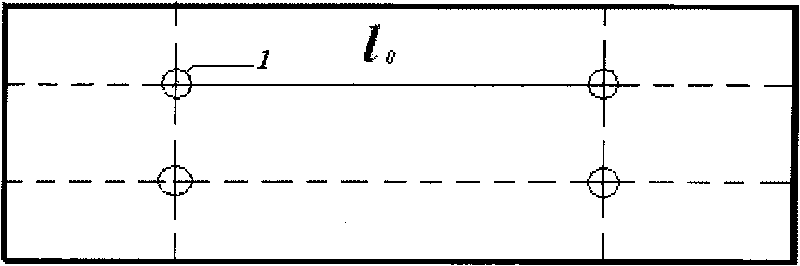

[0027] (1) Form 100mm×100mm×400mm prismatic concrete specimens, form 3 specimens for each concrete mix ratio, and pre-embed 4 copper heads parallel to the surface of the specimen during molding on each specimen as the end point of the measurement length Such as figure 1 As shown, the distance between the two copper heads along the length of the specimen is about 250mm. The concrete specimens were demolished one day after forming, placed in a standard curing room for curing, and the coefficient of thermal expansion was measured at the predetermined age.

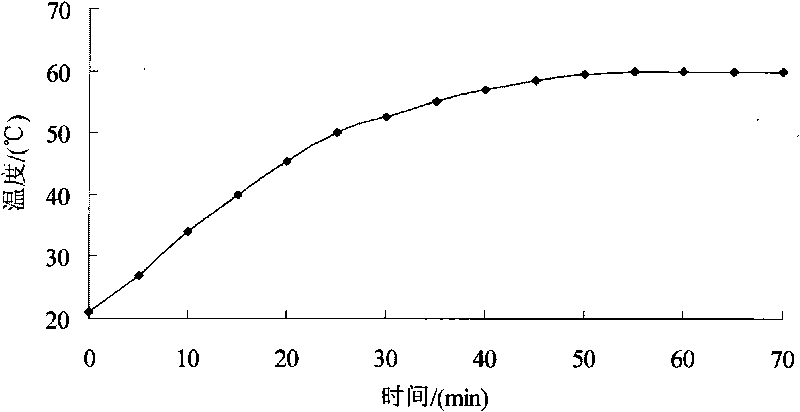

[0028] (2) When the set curing age is reached, first put the concrete specimen into 20°C water and soak it completely. Put the handheld strain gauge into the standard curing room half an hour before the measurement, so that the specimen and the handheld strain gauge have the same temperature. After the concrete specimen is fully immersed in water for 1.5h, measure and record the length between the corresponding two copper he...

Embodiment 2

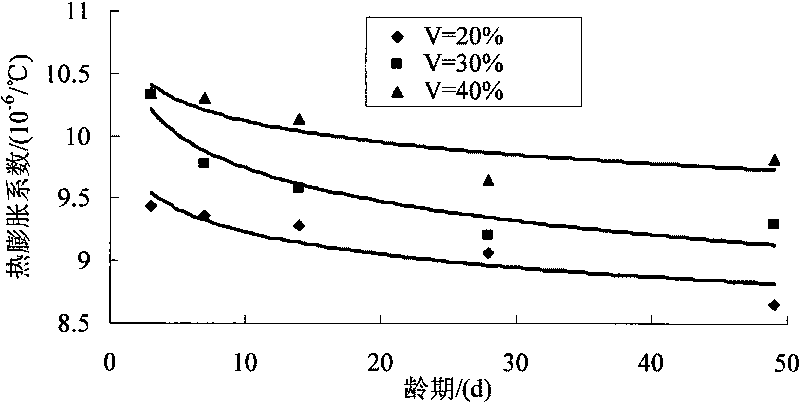

[0047] Under the experimental conditions of slurry water-binder ratio of 0.42, fly ash replacement amount of 25%wt, and sand ratio of 38%wt, the volume fraction V of slurry in concrete is 20%, 30%, and 40% respectively. Respectively form 3 test pieces under the condition, after forming, according to the method for embodiment 1, measure the coefficient of thermal expansion of concrete at different ages, test result is as follows image 3 shown. Because the thermal expansion coefficient of the hardened cement paste is higher than that of the aggregate, as the volume fraction of the paste increases, so does the thermal expansion coefficient of the concrete. This is the same as image 3 The trend of the detection results shown is consistent.

Embodiment 3

[0049] The total amount of cementitious material is 400kg / m 3 , the water-binder ratio is 0.42, the sand rate is 38%wt, and the mass fraction of fly ash in the slurry is 0, 0.1, 0.2, 0.3, 0.4 respectively. After standard curing 28d, test the thermal expansion coefficient of different dosage fly ash concrete according to the method for embodiment 1, as Figure 4 shown. In the case of the same amount of cementitious material, as the amount of fly ash increases, the porosity of cement stone increases, resulting in a decrease in the thermal expansion coefficient of concrete. This is the same as Figure 4 The trend of the detection results shown is consistent.

[0050] It can be seen from the examples that the measuring method is simple, the repeatability of the measuring results is good, and the error is also small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com