Fast measurement method for exhaust gas components and concentration and test instrument

A technology for testing instruments and components, applied in the direction of material electrochemical variables, etc., can solve the problems that cannot guarantee accuracy and cannot effectively solve the loss of sulfur dioxide, loss of gas dissolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

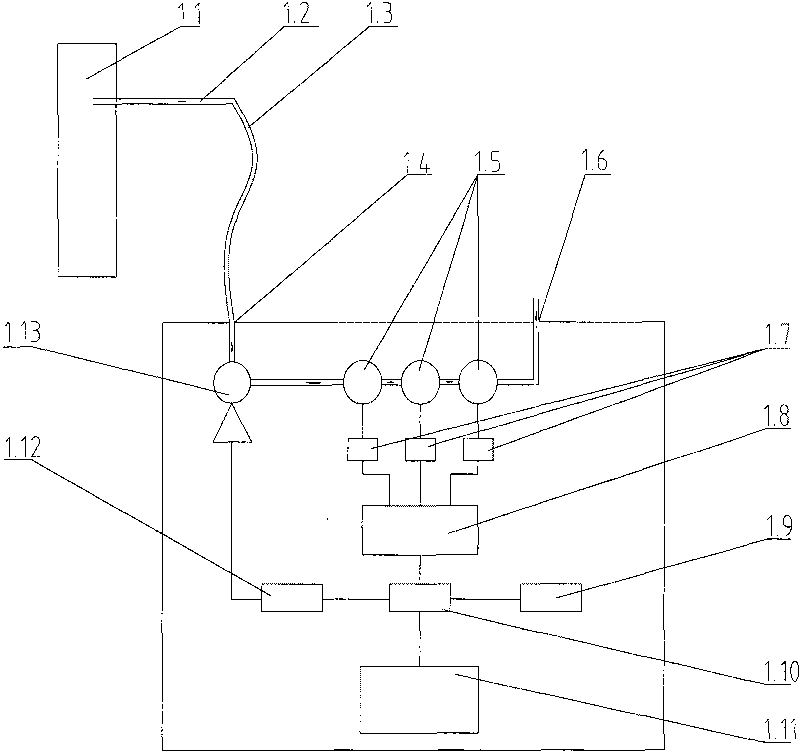

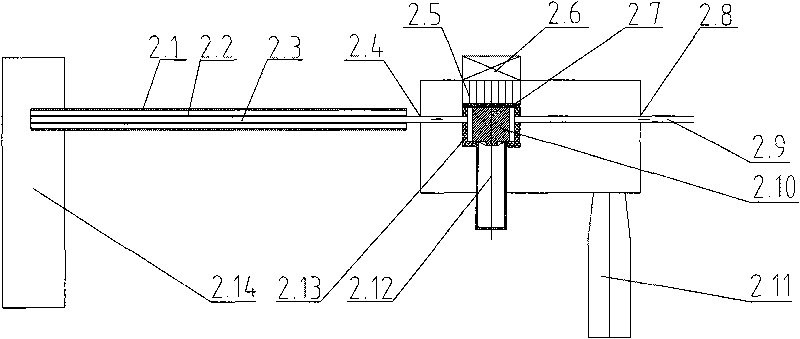

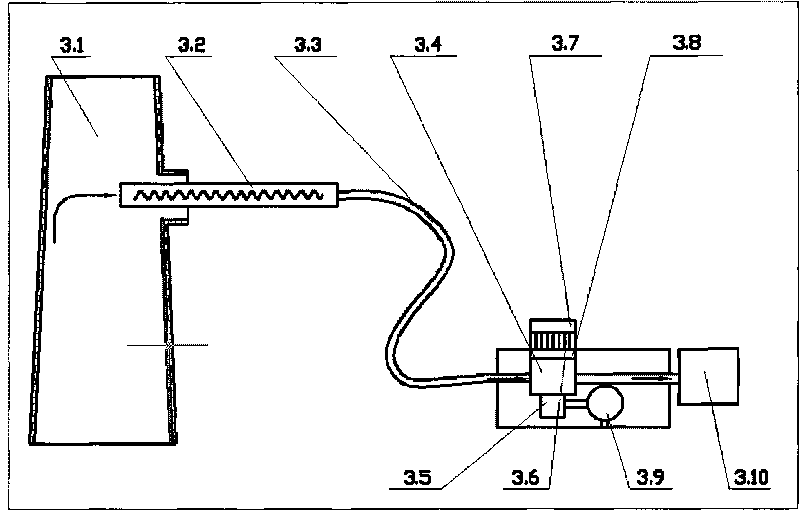

[0063] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0064] This method is based on the following studies:

[0065] To build a temperature control system in the laboratory, see attached Figure 7 , carry out the following experiments.

[0066] 1) SO with a concentration of 100ppm 2 Fill the air bag with standard gas, set the incubator to different temperatures, and test the output electrical signal of the sensor in the air bag, see Table 1:

[0067] Table 1. Effect of temperature change on sensor (sulfur dioxide) output

[0068]

[0069] Note: The measuring gas is a dry standard gas with zero humidity made up of 99.99% pure nitrogen and sulfur dioxide gas

[0070] 2) Set the temperature of the incubator to any temperature within 0-80°C, fill the air bag with 100ppm standard gas with different humidity, and measure the output electrical signal of the sensor, see Table 2:

[0071] Table 2. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com