Casting method of transformer or inductor

A casting method and inductor technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of magnetic core cracking, magnetic core cracking, inductance drop, etc., and achieve the effect of reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] a. Submerge the magnetic core completely in the silica gel primer treatment agent (model ZR2100), then take out the magnetic core and put it in an oven for drying at a temperature of 135°C for 25 minutes, then cool naturally after drying;

[0017] b. Submerge all the magnetic cores in organic potting silica gel (model ZR340), and air dry naturally after taking them out;

[0018] c. Repeat the process of step a once;

[0019] d, repeat the process of step b once;

[0020] e. After tightening the outer glass ribbon coil and magnetic core, adjust the inductance of the transformer or inductor to the upper limit, and then put it in the oven to preheat until the surface temperature reaches 75°C, and dry it at this temperature for 6 minutes. After natural cooling, wrap the glass ribbon as a whole for potting.

[0021] Before potting, fill the four corners of the transformer or inductor with glass ribbon, and ensure that the minimum distance between the magnetic core and the ...

Embodiment 2

[0030] a. Immerse the magnetic core completely in the silica gel primer treatment agent, then take out the magnetic core and put it in an oven for drying at a temperature of 140°C. The drying time is 30 minutes, and then naturally cool after drying;

[0031] b. Submerge all the magnetic cores in the organic potting silica gel, take them out and air dry them naturally;

[0032] c. Repeat the process of step a once;

[0033] d, repeat the process of step b once;

[0034] e. After tightening the outer glass ribbon coil and magnetic core, adjust the inductance of the transformer or inductor to the upper limit, then put it in the oven to preheat until the surface temperature reaches 80°C, and dry it at this temperature for 8 minutes. After natural cooling, wrap the glass ribbon as a whole for potting.

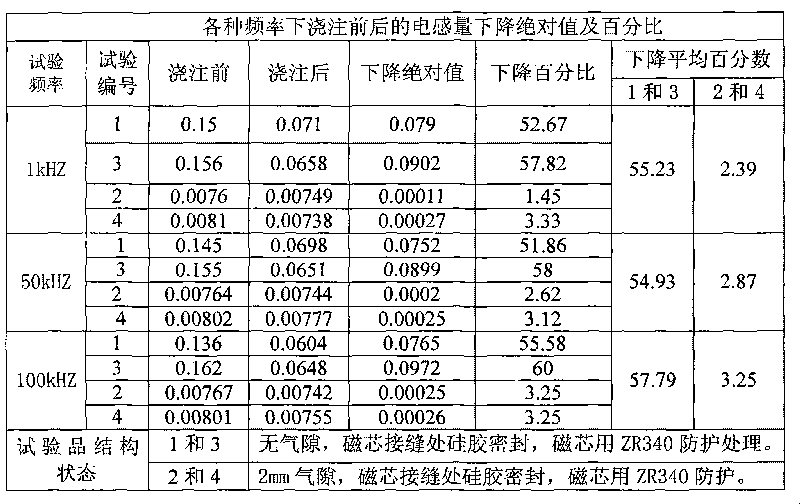

[0035] The silica gel bottom coating treatment agent used in the specific embodiment of the present invention adopts the product of Wuxi Lily Flower Adhesive Factory, and the freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com