Pore channel cooling method of damaged cooling wall of blast furnace and device thereof

A cooling method and technology of cooling wall, applied in the direction of cooling device, etc., can solve the problem of small passage, achieve the effect of stable airflow, conducive to maintenance, and avoid enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

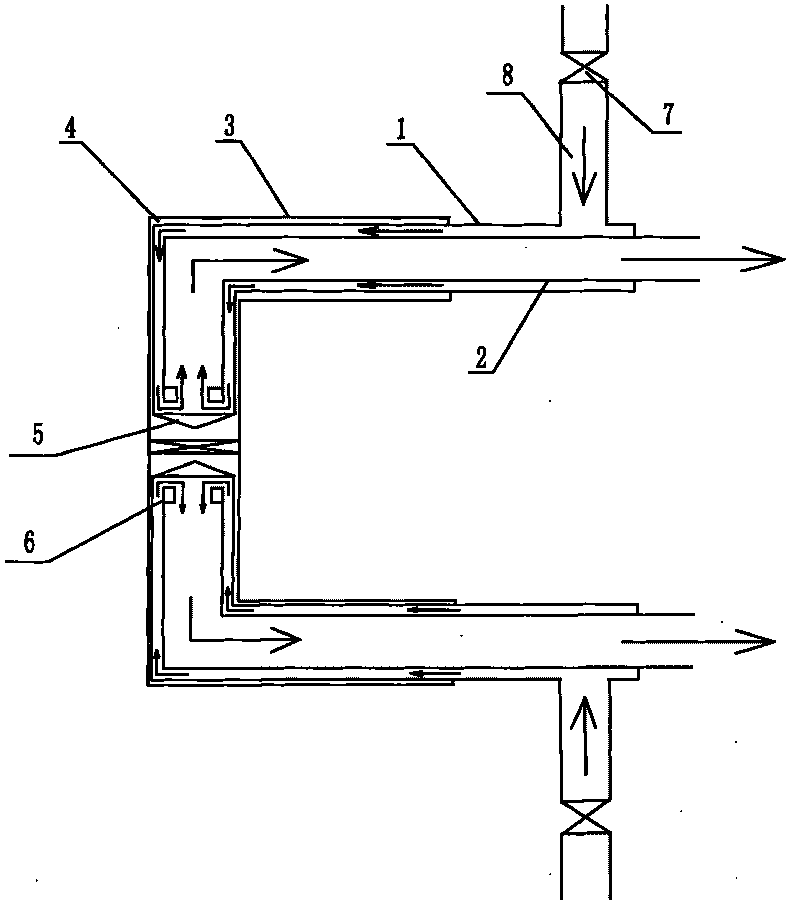

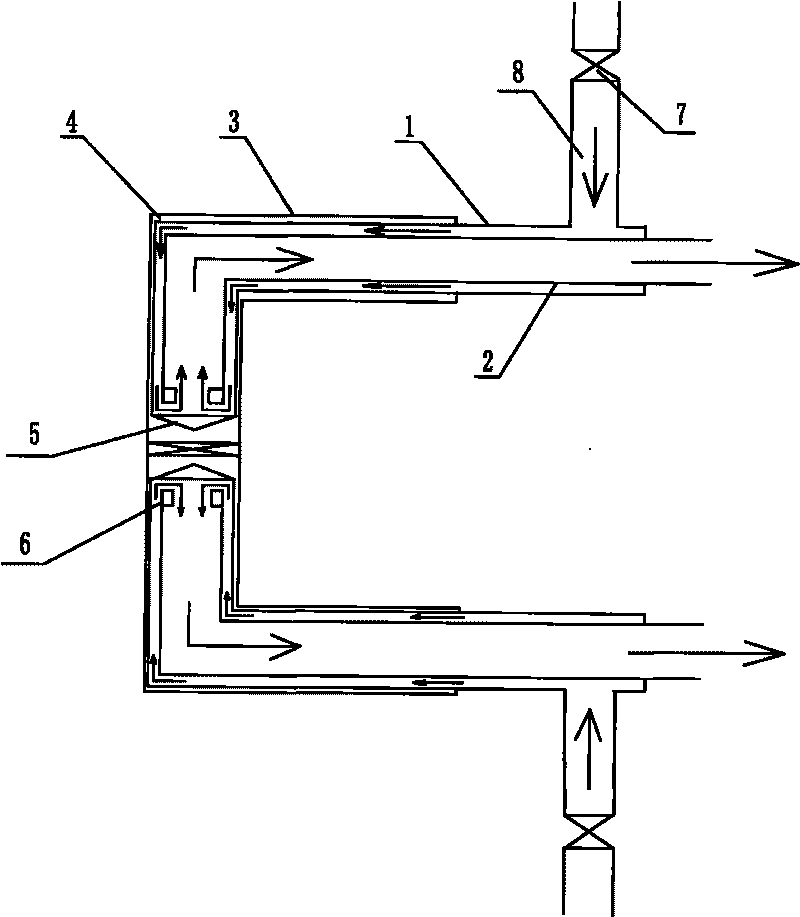

[0017] The cooling method of the blast furnace damaged stave channel is carried out according to the following steps:

[0018] (1) Separate the damaged cooling wall for the cooling wall that is blocked or close to blocking the cooling channel;

[0019] (2) Insert a metal corrugated hose into the water inlet pipe and outlet pipe of the cooling wall, and plug the front end of the metal corrugated hose with a plug;

[0020] (3) Insert a metal corrugated hose with a smaller diameter into the metal corrugated hose, plug the front end of the hose with a plug, and open several small holes on the plug;

[0021] (4) Fill the slurry with high thermal conductivity between the cooling wall and the large metal corrugated hose. The slurry with high thermal conductivity can be silicon carbide, silicon nitride or carbon material.

[0022] (5) The water supply pipe is connected to the rear end of the large metal corrugated hose, and the cooling water passes through the cavity formed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com