Leak-detecting method for cooling system of blast furnace

A cooling system and leak detection technology, applied in cooling devices, inspection devices, etc., can solve the problems of not being able to accurately indicate the exact location of cooling wall leakage, difficulty in leak detection, and wrong judgments, and achieve strong operability, easy mastery, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

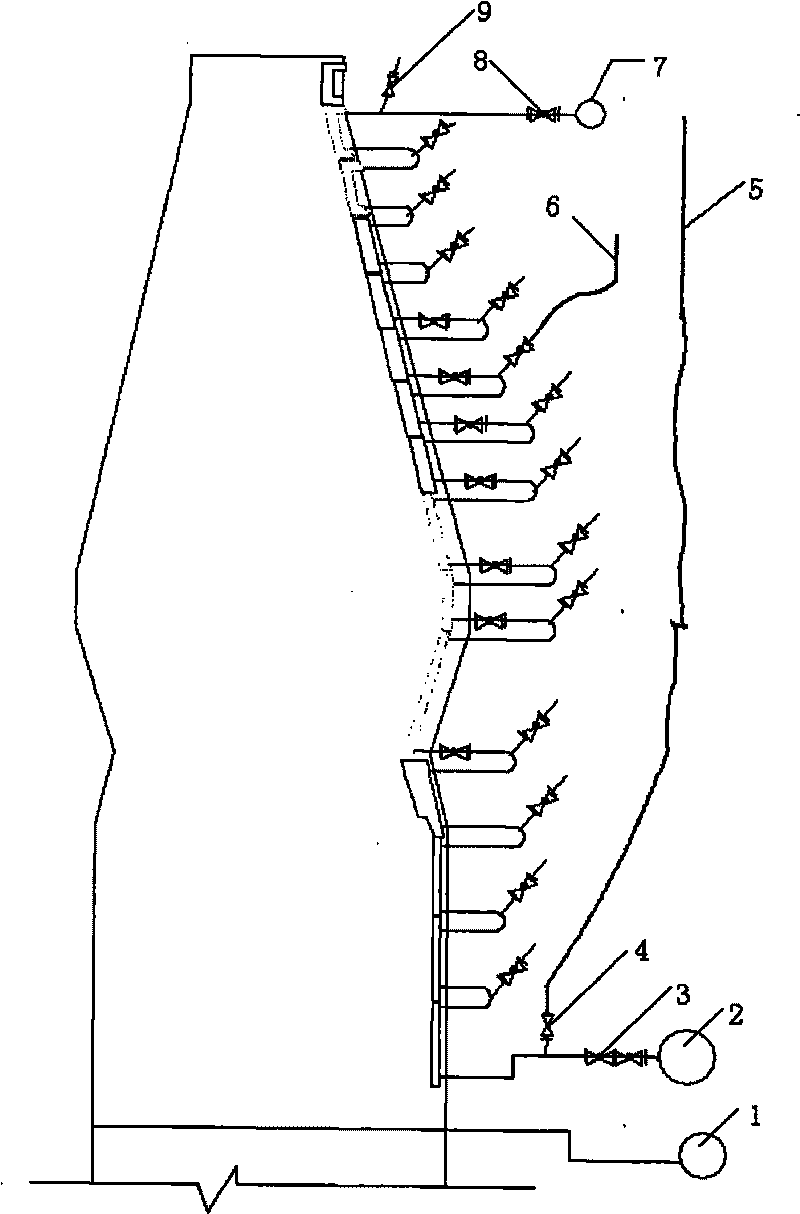

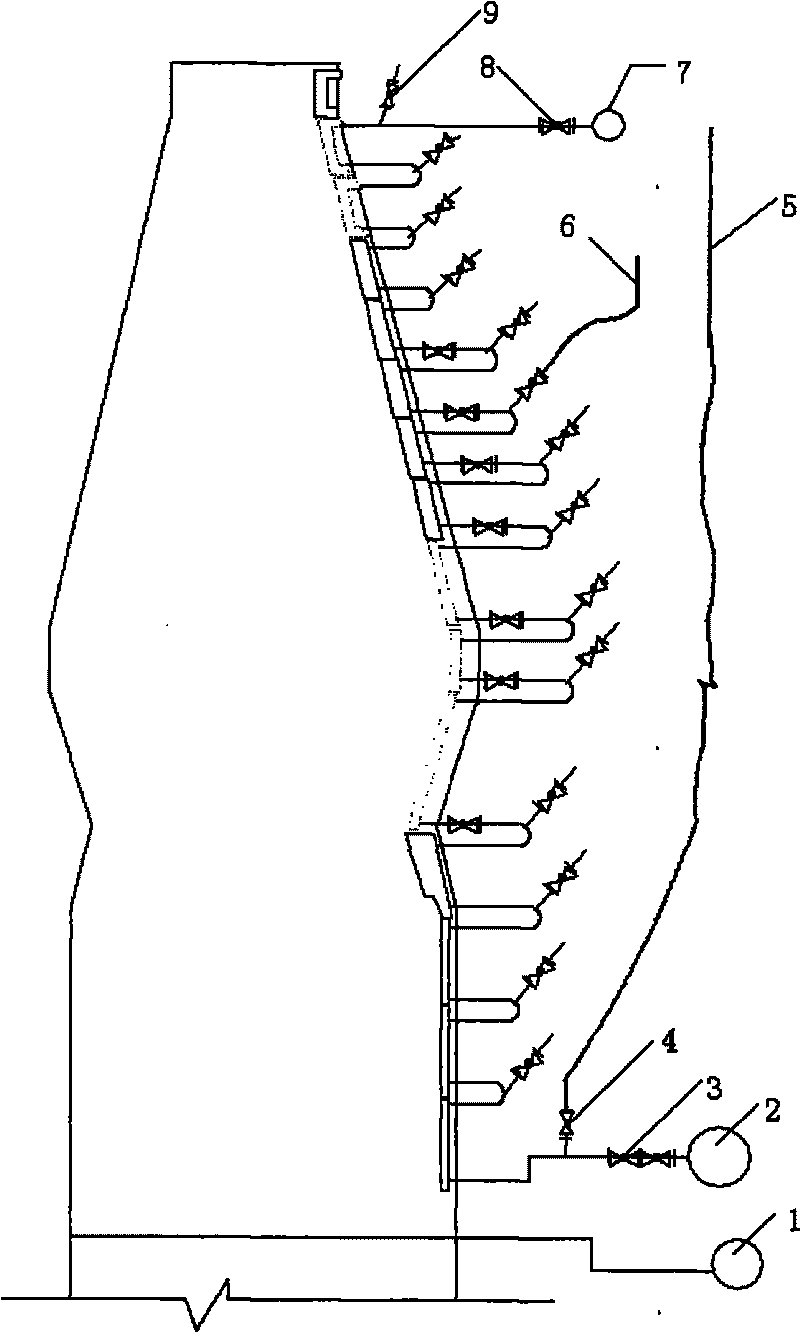

[0017] The present invention will be further described below with reference to the drawings and embodiments.

[0018] As shown in the figure, the bottom of the blast furnace has a bottom water supply pipe 1, the cooling pipe of the blast furnace is connected to the water supply loop 2, and the highest section of the cooling pipe of the blast furnace is connected to the return water collection pipe 7. The scheme of the present invention is: After the leaking cooling pipe, first connect a transparent pipe 5 to the exhaust valve 4 of one of the cooling pipes in the middle of the cooling pipe, and then close the lower communicating valve 3 of the cooling pipe to ensure that it is completely cut off from the lower cooling pipe. And fill the upper cooling pipe with water, then close the return valve 8 of the cooling pipe, open the exhaust valve 9 of the highest section of the cooling pipe, and then raise the end of the transparent tube 5 to the highest section of the cooling pipe. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com