Mechanical continuous variable valve lift driving device

A valve lift and driving device technology, applied in the direction of valve devices, mechanical equipment, machines/engines, etc., can solve the problems of increasing fuel consumption and pumping loss of the whole machine, so as to reduce fuel consumption, reduce pumping loss and improve power performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

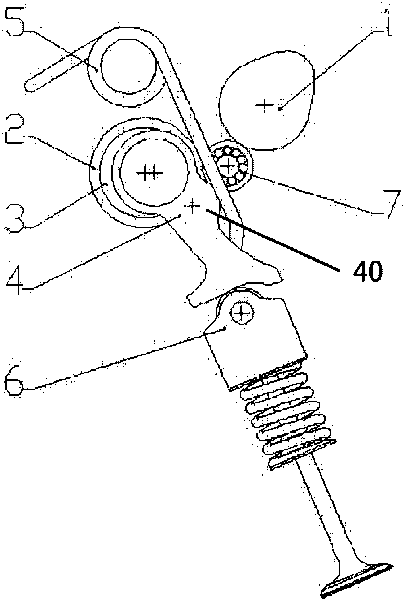

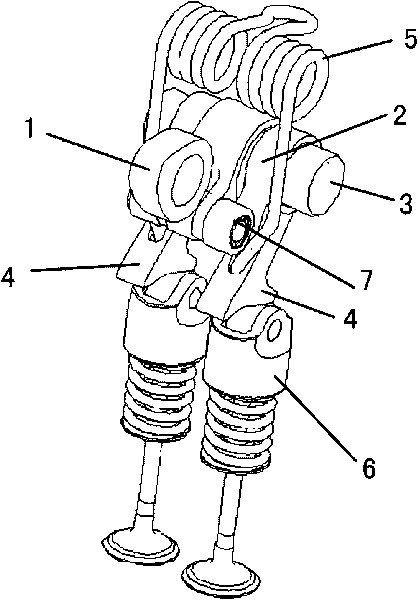

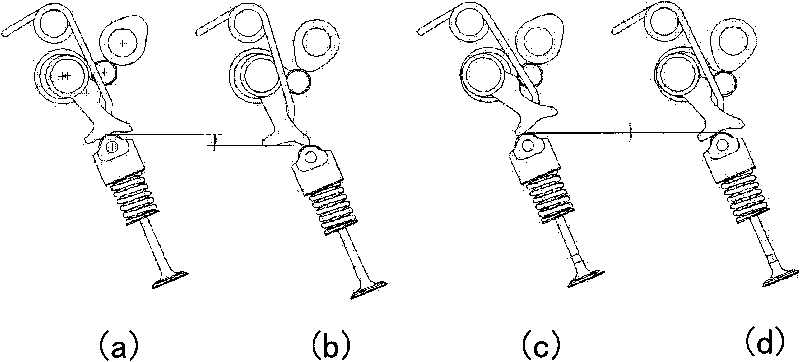

[0018] Such as figure 1 with figure 2 As shown, the mechanical continuously variable valve lift driving device of the present invention is used to drive a tappet type valve spring assembly or a rocker arm type valve spring assembly with a special profile as a valve lift-opening continuous continuously adjustable solution.

[0019] The mechanical continuously variable valve lift driving device of the present invention includes a swing arm 4, a rocker arm 2, a control shaft 3, a cam 1 and a return spring assembly 5. The swing arm 4 is installed on the control shaft 3 and can be wound around the control shaft 3 Reciprocating swing, the end face of the far end of the swing arm 4 relative to its swing fulcrum (i.e. the control shaft 3) is a cam profile, which is used to interact with the valve spring assembly 6. The arc surface of the center of the circle (the base circle segment) and at least one section of the function arc surface (working section), the function arc surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com