Device for automatic counting and pin checking of tube circuit

A technology of pins and circuits, applied in the field of equipment for automatic counting and pin inspection of integrated circuits mounted in tubes, can solve the problems of points and inspection errors, increase in IC points and inspection costs, and easy fatigue, etc., to achieve a simple structure , easy maintenance, automatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

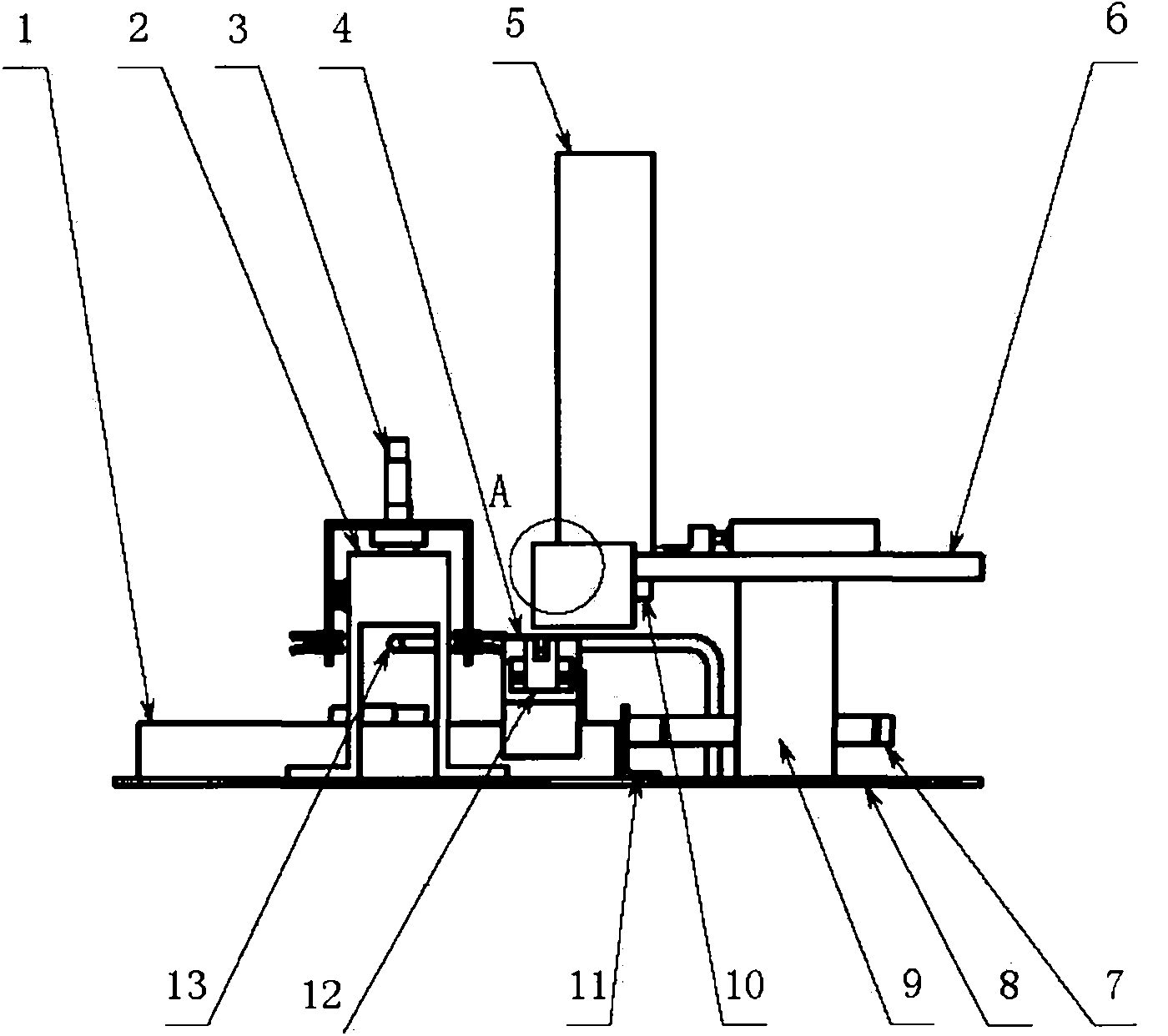

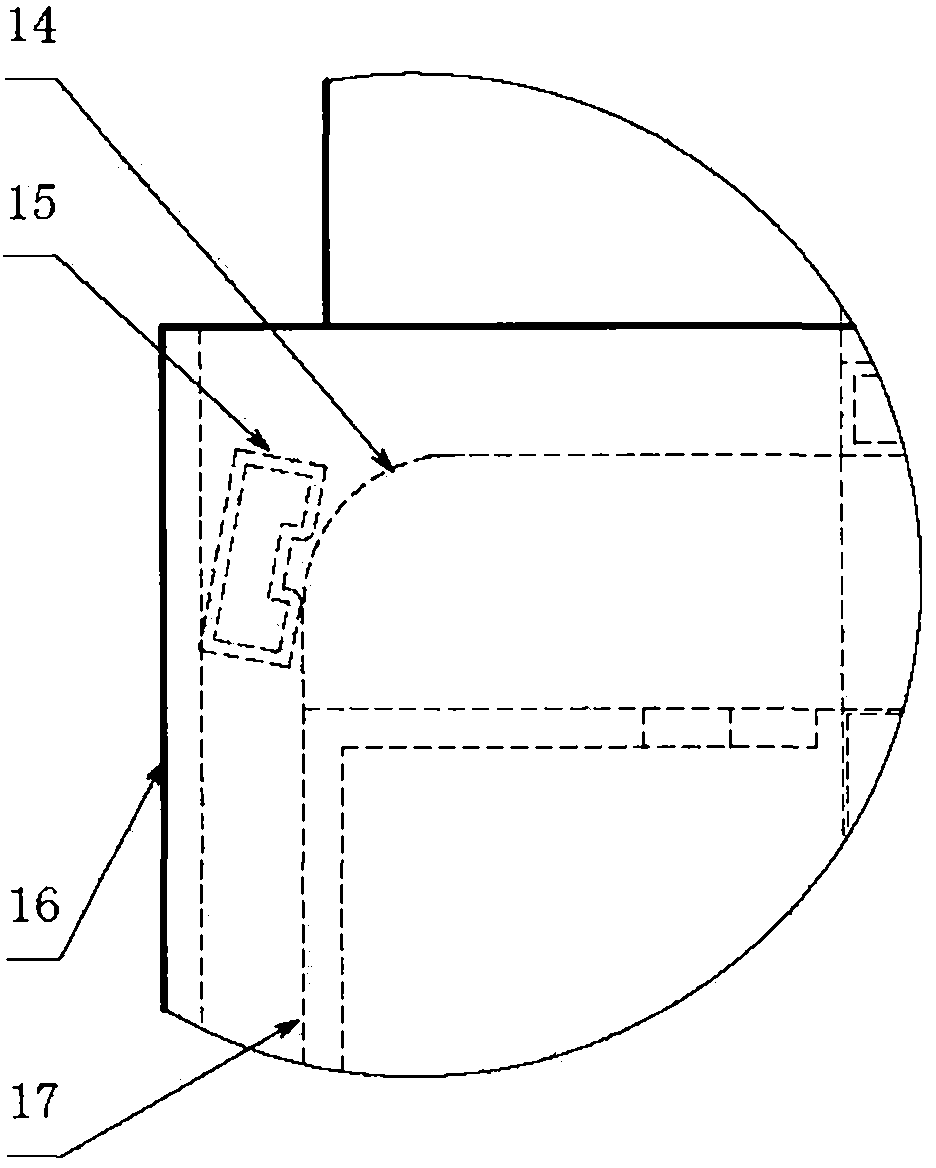

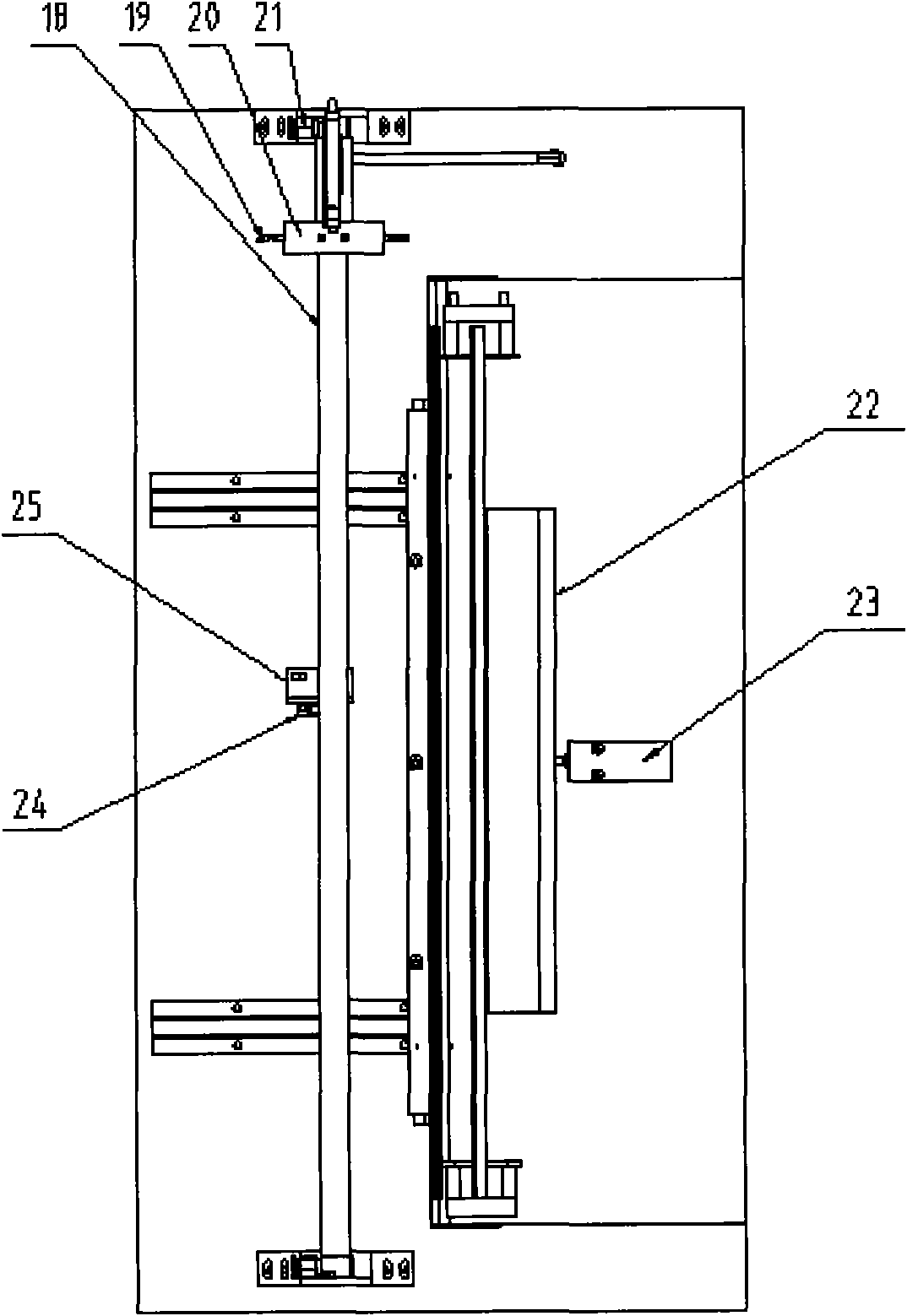

[0016] Such as Figure 1~6 Shown: The automatic counting and pin inspection machine for the material tube circuit includes linear slide rail 1, pneumatic slide table support frame 2, pin detection sensor amplifier 3, card material chute 4, feeding chute frame 5, feeding base 6, the first A pushing cylinder 7, a worktable panel 8, a support frame 9, a trough sensor 10, a pushing cylinder fixing frame 11, a material jam sensor 12, an air blowing pipe 13, a guide arc groove 14, a circuit material pipe 15, a first limiter Position plate 16, second limit plate 17, pneumatic slide table 18, pin detection sensor 19, pin detection sensor fixing frame 20, air pipe quick connector 21, pusher plate 22, second pusher cylinder 23, in-position sensor 24 And sensor bracket 25 etc. in place.

[0017] The support plate 9 is connected to the workbench panel 8, the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com